Materials of electronic paper micro-cup and preparation method

An electronic paper and microcup technology, applied in coating, optics, instruments and other directions, can solve the problems of high difficulty of molding process, fragile structure of microcup, easy to react, etc., and achieves easy mass production, simple method, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

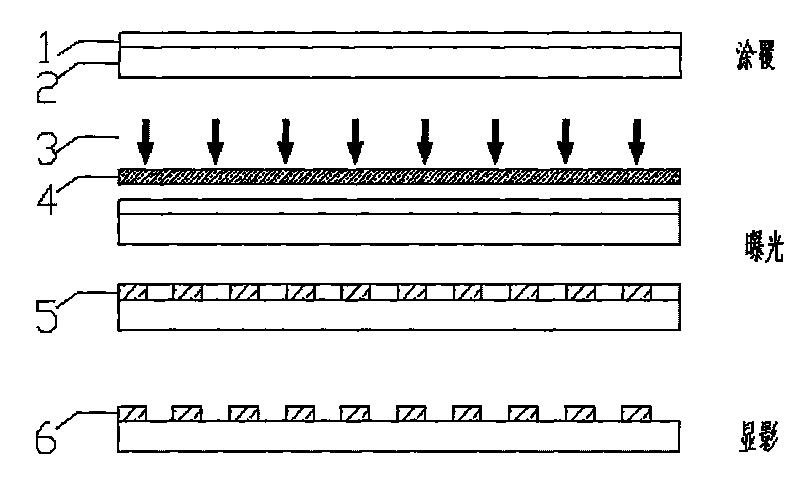

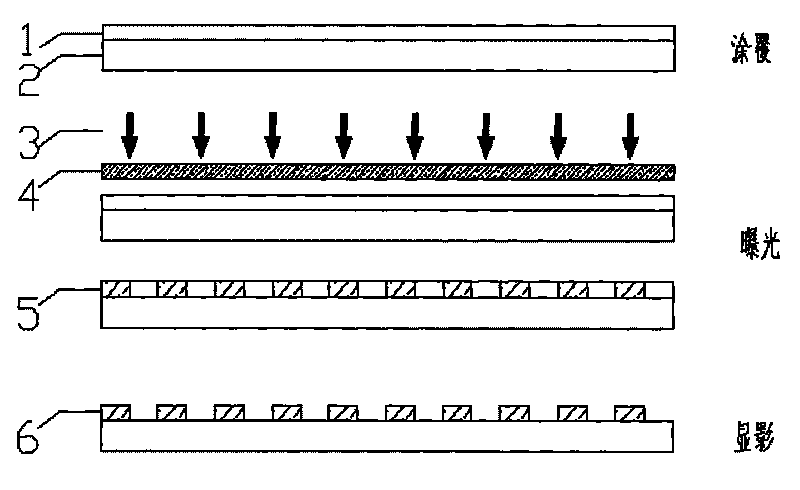

Method used

Image

Examples

Embodiment 1

[0027] The preparation of the photolithographic electronic paper microcup material adopts the following process: get 50 grams of glass powder barium oxide (BaO) and pour it into a mortar, add Texanol ester alcohol (2,2,4-trimethyl-1.3 pentanediol mono Isobutyrate) 20g, methyl methacrylate resin 25 grams, active ingredient photoinitiator 2-methyl-1-[4-methylthiophenyl]-2-morpholino-1-acetone 3g, disperse Agent BYK2025 2g, grind for 5-15 minutes.

[0028] The above-mentioned glass powder can be a granular body made by melting and pulverizing, and the glass powder whose particle size is less than 10 μm can also be prepared by using directly purchased glass powder. The same below.

[0029] The method for making a microcup pattern by using the above-mentioned photoetching type microcup material is as follows:

[0030] 1) Wash the polyethylene terephthalate (PET) substrate with deionized water and dry it at low temperature (baking at 60°C for 10 minutes);

[0031] 2) Print and co...

Embodiment 2

[0039] The preparation of photolithographic electronic paper microcup material adopts the following process: take glass powder boron oxide (B 2 o 3 ) 22 grams into the mortar, add Texanol ester alcohol (2,2,4-trimethyl-1.3 pentanediol monoisobutyrate) 30g, methyl methacrylate resin 40 grams, active ingredient photoinitiator 2-methyl-1-[4-methylthiophenyl]-2-morpholino-1-propanone 4g, dispersant BYK140 4g, grind for 5-15 minutes.

[0040] The method for making a microcup pattern by using the above-mentioned photoetching type microcup material is as follows:

[0041] 1) The glass substrate is cleaned with isopropanol after ultrasonication with clean water;

[0042]2) Print and coat the above-mentioned microcup material on the substrate with electrode pattern by inkjet method;

[0043] 3) After baking at 90°C for 30 minutes, the coating layer is cured to form a film with a thickness of 10 μm;

[0044] 4) Continue to spray a layer of microcup material on the baked film-forming...

Embodiment 3

[0051] The preparation of the photolithographic electronic paper microcup material adopts the following process: get 56 grams of glass powder zinc oxide (ZnO) and pour it into a mortar, add Texanol ester alcohol (2,2,4-trimethyl-1.3 pentanediol mono Isobutyrate) 10g, methyl methacrylate resin 15 grams, active ingredient photoinitiator 2-methyl-1-[4-methylthiophenyl]-2-morpholino-1-acetone 4g, disperse Agent BYK180 2g, antifoaming agent dimethyl polysiloxane 2g, grind for 5-15 minutes.

[0052] The method for making a microcup pattern by using the above-mentioned photoetching type microcup material is as follows:

[0053] 1) The glass substrate is cleaned with acetone after ultrasonication with clear water;

[0054] 2) Print and coat the above-mentioned microcup material on the substrate with electrode pattern by rolling coating;

[0055] 3) After baking at 100°C for 8 minutes, the coating layer is cured to form a film with a thickness of 5 μm;

[0056] 4) Continue to roll-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com