Hybrid current collector used for lead storage batteries

A lead-acid battery and current collector technology, applied in electrode carriers/current collectors, battery pack components, circuits, etc., can solve problems such as large overload current on the interface surface, hydrogen evolution and capacity loss, insufficient mechanical strength, etc., and achieve material cost. Low, high weight-to-energy, light-weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

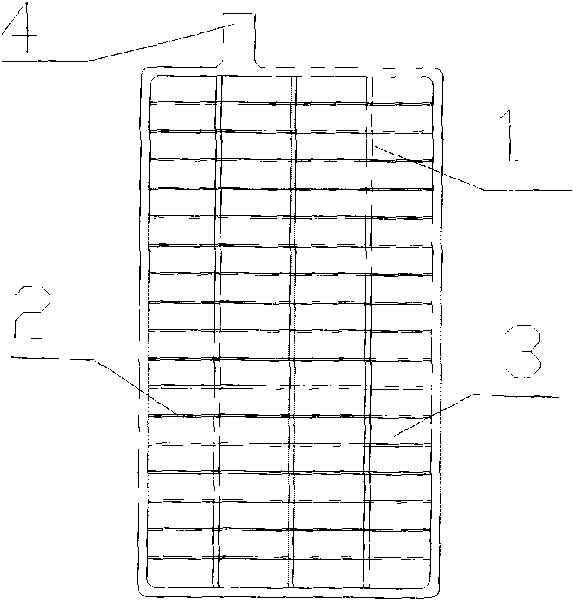

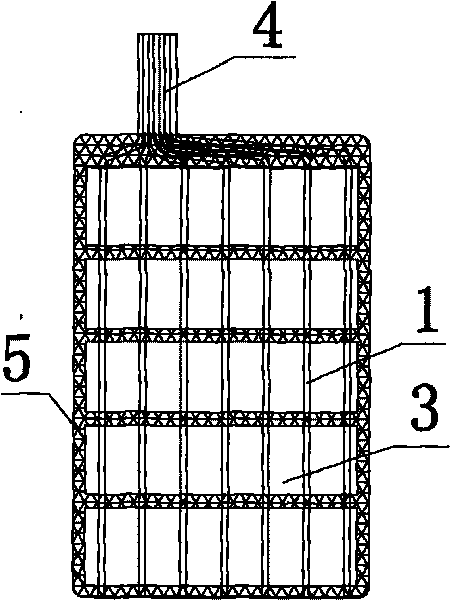

[0056] A hybrid current collector with a shape similar to a conventional grid was produced, and the current collector was designed as a rectangle with a width of 50 mm and a length of 72 mm, and a thickness of 2.5 mm. Firstly, the lead alloy skeleton is made by cold rolling or hot casting, and the side structure of the skeleton is as follows: image 3 As shown, 6 vertical ribs 1 are set, and the vertical ribs are circular with a diameter of 2mm, without horizontal bars 2, and the extension shape of the vertical ribs is also used as a pole ear 4, and the height of the pole ears is 12mm. The lead alloy skeleton is thermoformed with ABS plastic 5 in a special mold. The plastic frame includes four frames and four horizontal bars in the frame. The frame width of the four frames is 1.5mm, the width of the horizontal bars is 1.2mm, and the thickness is 2.5mm. Figure 6 As shown, the shape and structure of the current collector after thermoplastic molding is shown in FIG. 2 . The wei...

Embodiment 2

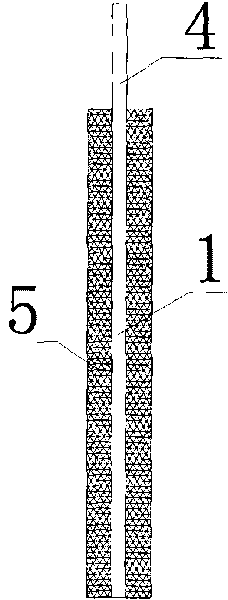

[0058] The pole lug described in embodiment 1 and the lead alloy skeleton are deformed, and the pole lug 4 is made as an attached Figure 4 The integrated structure shown is similar to the lead alloy skeleton, only the vertical rib 1 is designed, and there is no horizontal bar 2, which is similar to the thermoplastic molding method of ABS plastic 5. The shape and structure of the current collector after thermoplastic molding are as follows: Except for the integrated structure, the implementation effect is similar to that of Embodiment 1.

[0059] Since the thermoplastic molding of the four frames of the grid in Embodiment 1 and Embodiment 2 is ABS plastic, the auxiliary current collection capacity of the left and right vertical frames is lost. To strengthen the current collection capacity of the current collector, lead The surface area of the vertical rib 1 of the alloy skeleton is increased, or further technical improvement is implemented.

Embodiment 3

[0061] The frame surface of the ABS plastic 5 described in embodiment 2 and the lead alloy skeleton thermoplastic molding is processed into a regular concave-convex surface, and the thickness (maximum value) between the convex surfaces on both sides is 2.5mm, and the two sides are electroplated and dipped. , spraying and other conventional industrial methods cover a layer of lead on the plastic surfaces on both sides, so that the surface of the hard plastic 5 is changed into a lead-coated layer. In this embodiment, because the surface of the ordinary hard plastic is changed to lead-coated, the contact area between the current collector and the electroactive material is increased, the current collection capacity of the current collector is strengthened, and the large current charge and discharge capacity of the plate is improved. improve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com