Chemical mechanical polishing solution

A chemical mechanical and polishing liquid technology, applied in the field of polishing liquid, can solve problems such as material defects and erosion, multi-particle pollutants, surface step depth, etc., and achieve the effects of reducing impact, improving removal rate, and good surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~25

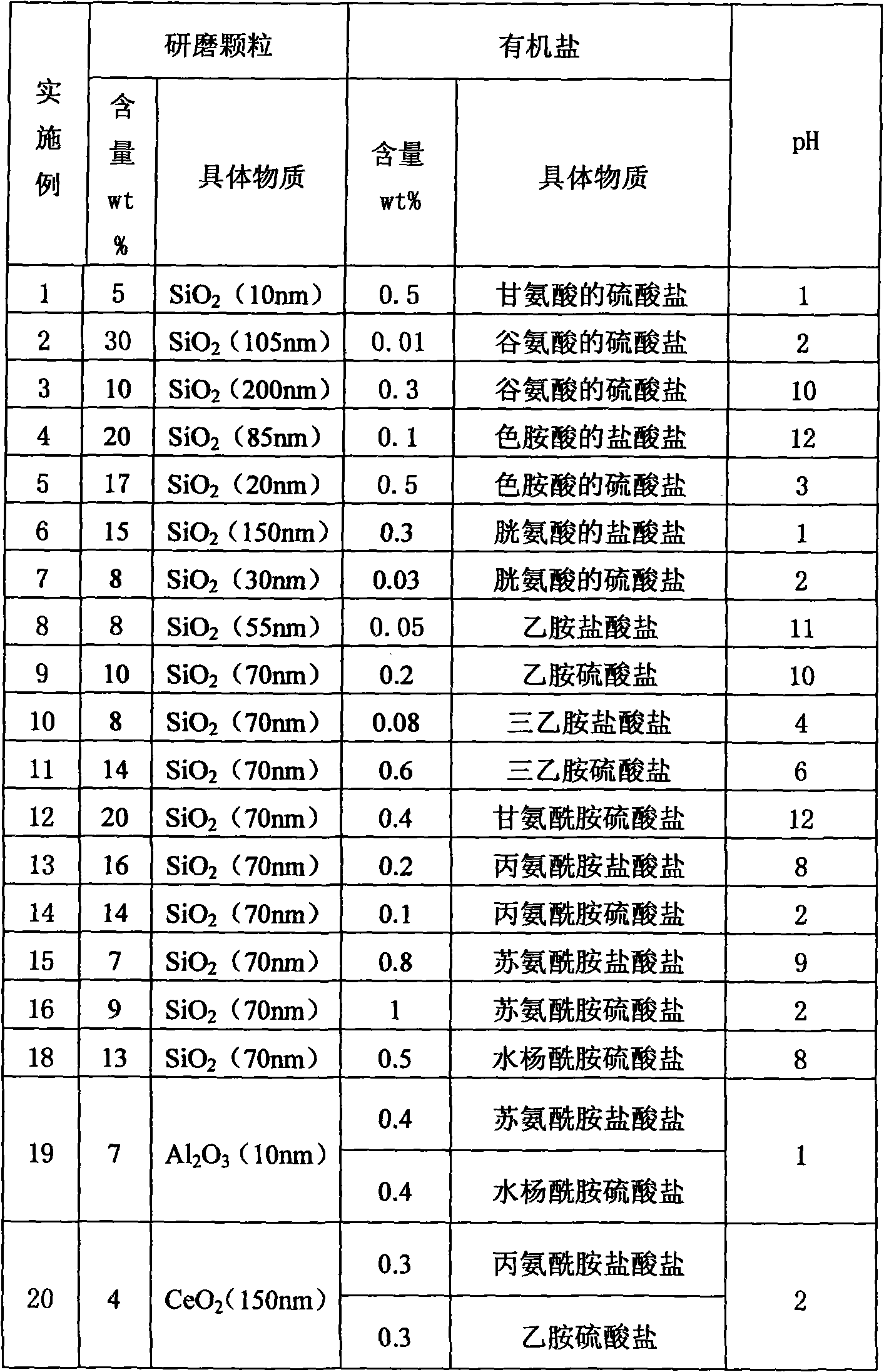

[0022] Table 1 provides chemical mechanical polishing liquid embodiment 1~25 of the present invention, according to the formula in the table, each component is mixed simply and evenly, the mass percent of polishing liquid is supplemented with water 100%, adopts potassium hydroxide, ammoniacal liquor and nitric acid to adjust afterwards To a suitable pH value, the polishing liquid of each embodiment can be prepared. SO 2 All are sol particles.

[0023] Table 1 chemical mechanical polishing fluid 1~25 of the present invention

[0024]

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com