Dual side cooling integrated power device package and module and methods of manufacture

A technology for integrating power and molding materials, which is applied in semiconductor/solid-state device components, semiconductor devices, electrical components, etc., and can solve the problem that the module footprint is not the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

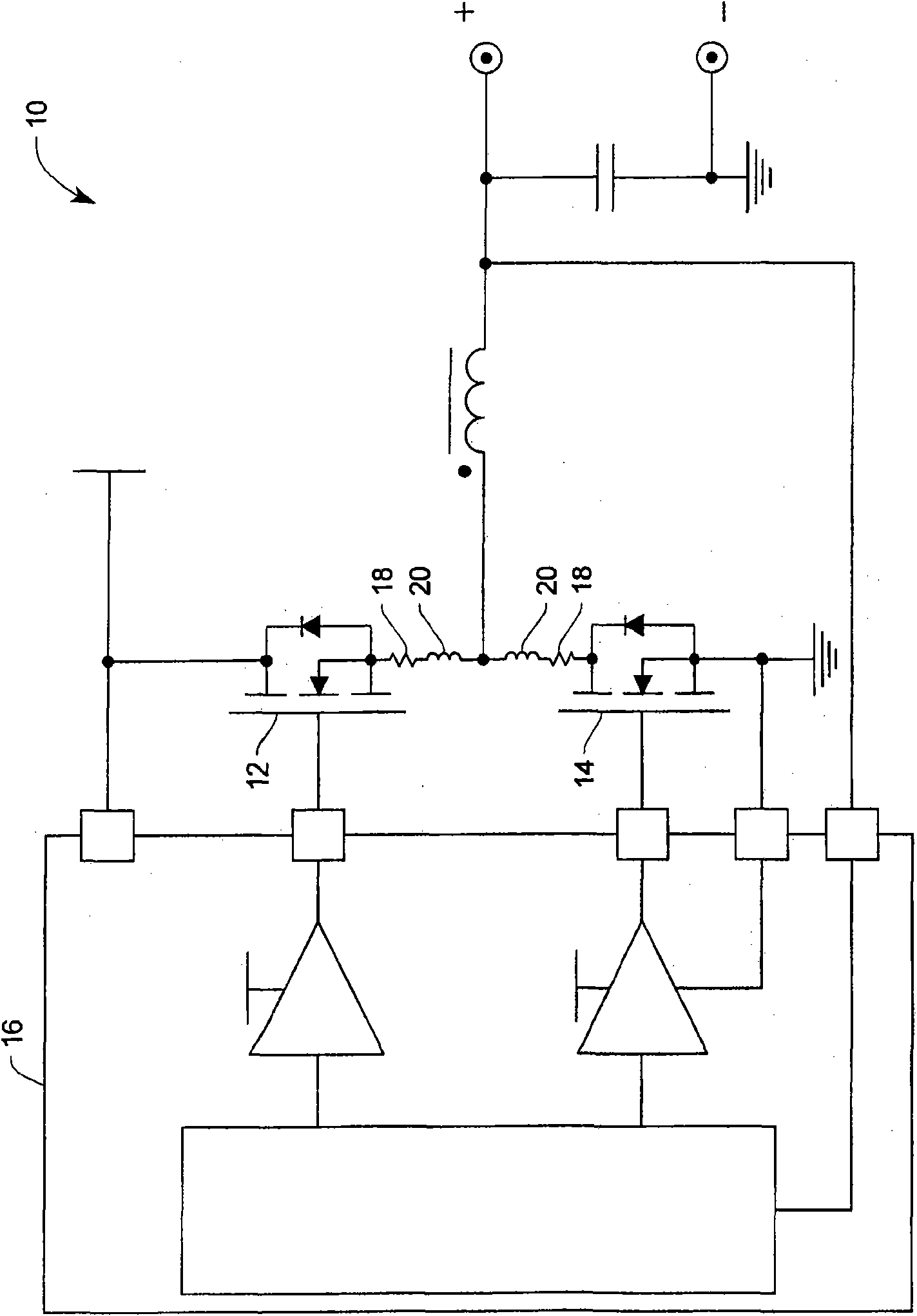

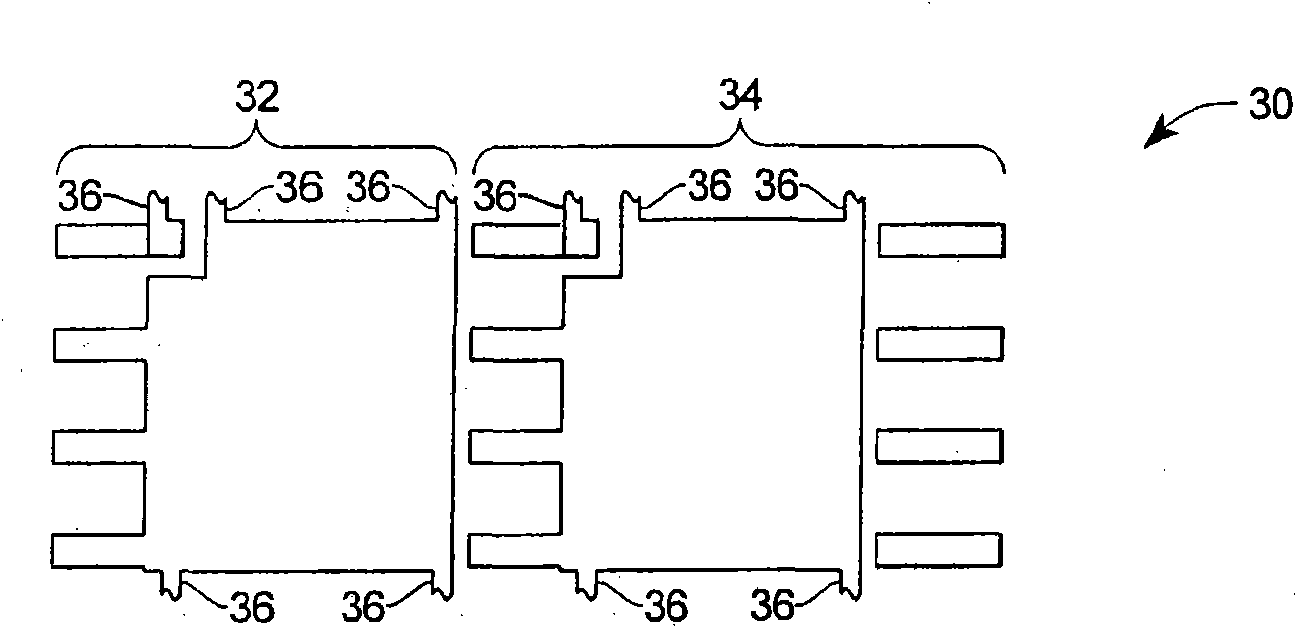

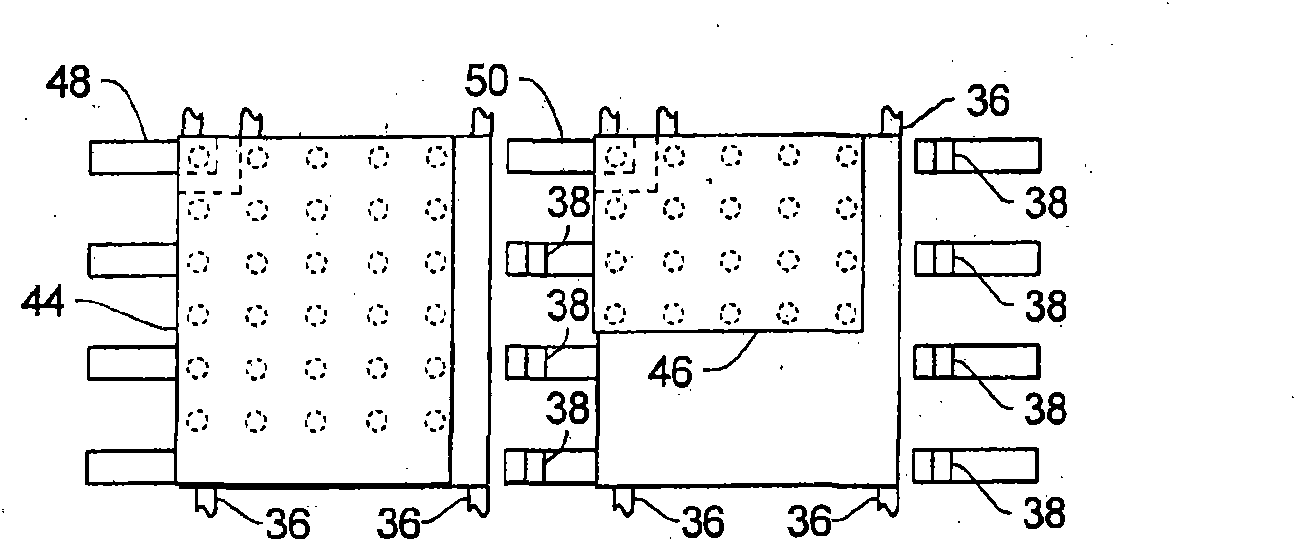

[0056] Embodiments of the invention are directed to semiconductor die packages and methods for manufacturing semiconductor die packages. A semiconductor die package according to an embodiment of the present invention includes a substrate and a semiconductor die mounted on the substrate. The semiconductor die may be attached to the substrate using an adhesive or any other suitable attachment material. In semiconductor die packaging, the bottom surface and / or the top surface of the semiconductor die may be electrically coupled to conductive regions of the substrate. The encapsulation material may encapsulate the semiconductor die. As will be explained in further detail below, substrates according to embodiments of the invention may have different configurations in different embodiments.

[0057] The substrate may have any suitable configuration. However, in a preferred embodiment of the invention said substrate comprises a lead frame structure and a molding material. Typical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com