Bonding system of high-reliability thick-film mixed integrated circuit and manufacturing method thereof

A thick-film hybrid and integrated circuit technology, which is applied in circuits, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of no high-reliability thick-film hybrid integrated circuit bonding system reports, difficult compatibility, and bond strength decline, etc. problems, to achieve the effect of improving the ability to work fully and reliably for a long time, high safety and reliability, and improving bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

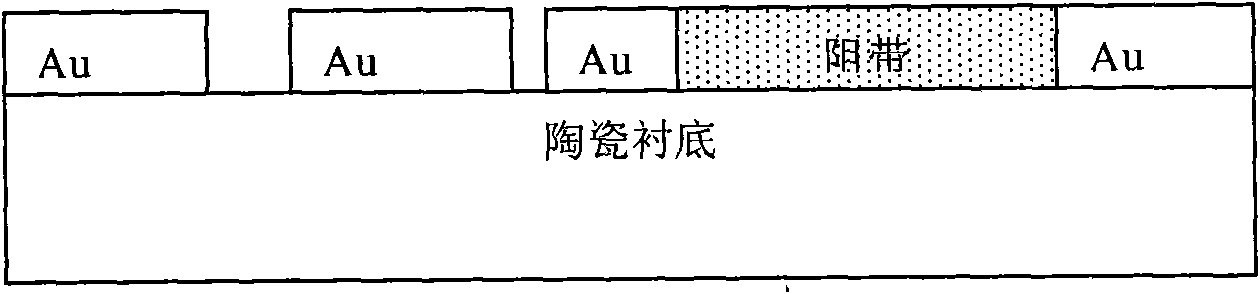

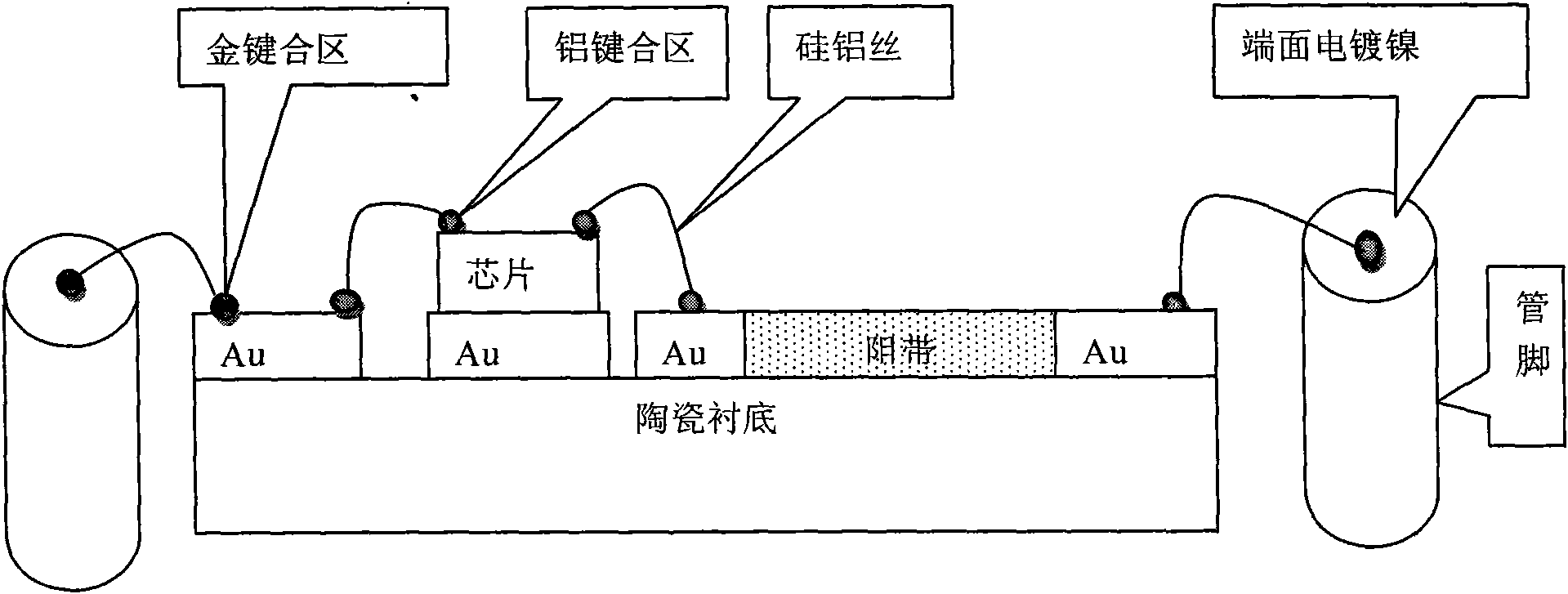

[0023] The FH0186 power operational amplifier developed by Guizhou Zhenhua Fengguang Semiconductor Co., Ltd. is a thick-film hybrid integrated circuit. The material of the conduction band and the bonding area is sintered at high temperature with conventional gold paste, and the bonding area of the end surface of the pin is gold-plated or plated. The bonding area on the surface of the semiconductor integrated circuit chip is formed by conventional aluminum materials. In the past, the selection of bonding wire was very difficult. Whether gold wire or silicon-aluminum wire was used, there would be a weak gold-aluminum (Au-Al) bonding system, and the entire bonding process could not be compatible. Can not meet the requirements of the relevant users.

[0024] After research, the company cleans and dries the original thick film substrate with ultrasonic waves, and then positions and aligns with the metal mask and fixes it with a special fixture. In the high vacuum magnetron sputte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com