Toner for electrostatic development, image forming appratus

A technology of toner and electrostatic charge, which is applied in the field of toner for electrostatic charge development and image forming devices, which can solve problems such as image defects and achieve a good effect of maintaining chargeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

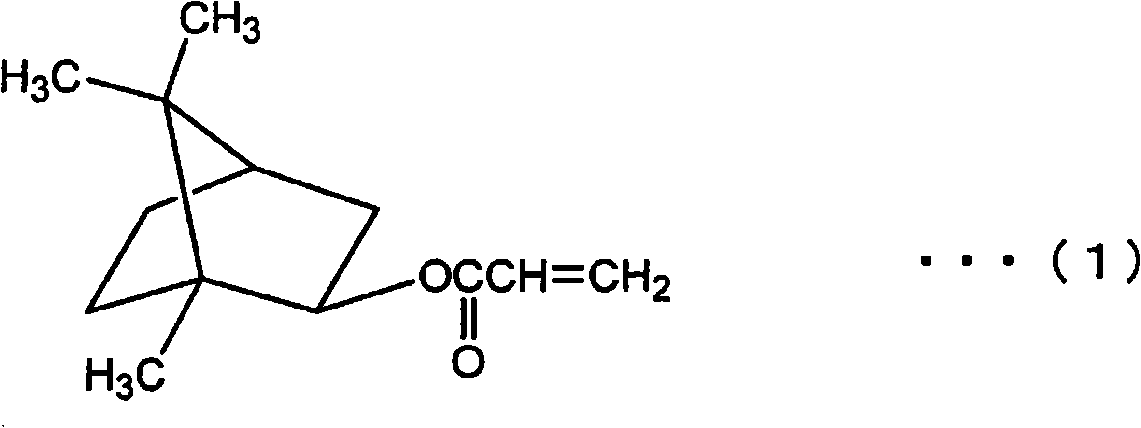

Method used

Image

Examples

preparation example Construction

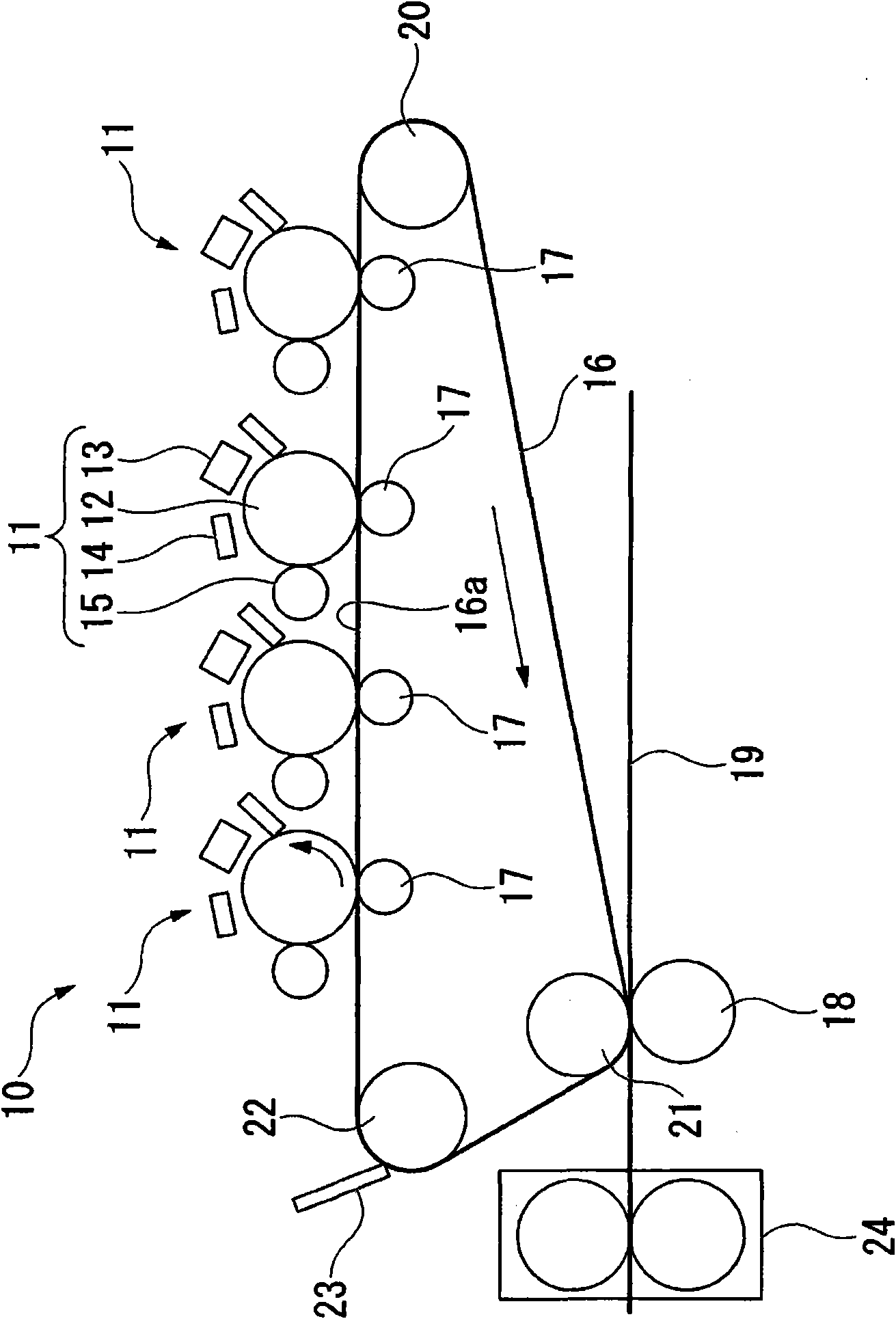

[0038] (Preparation method of toner mother particles)

[0039] The toner base particles can be prepared by known kneading and pulverization methods, polymerization methods, spinning methods, and the like. For example, when a kneading and pulverization method is used, the preparation is carried out in the following procedure. First, necessary raw materials such as the above-mentioned binder resin, a colorant according to the color of the toner, a charge control agent, and wax are mixed with a mixer such as a Henschel mixer. Then, after melting and mixing with a twin screw extruder or the like, it is pulverized with a crusher such as a hammer crusher. Then, the toner base particles can be obtained by performing classification with a classifier such as an airflow classifier.

[0040] The volume-based average particle diameter of the toner core particles thus obtained is preferably 3.0 μm to 10.0 μm.

[0041] In addition, the volume-based average particle diameter of the toner base pa...

Embodiment 1

[0116]

[0117] To 100 parts of a polyester resin (manufactured by Mitsui Chemicals, Almadex P645) obtained by condensing bisphenol and fumaric acid as a binder resin, a copper phthalocyanine pigment (pigment blue 15-3 (manufactured by BASF, Heliogen Blue D7079)) 4 parts, 2 parts of a quaternary ammonium compound (manufactured by ORIENT CHEMICAL, "Bontron P-51") as a charge control agent, and Fischer-Tropsch synthetic wax as a wax (manufactured by NIPPON SEIRO, "FT- 100”) 3 copies. The mixture was put into a Henschel mixer (manufactured by Mitsui Mine Co., Ltd.) and mixed for 2 minutes. Then, it was melt-kneaded with a twin-screw extruder to prepare a toner kneaded product. The obtained toner kneaded product was finely pulverized with a jet mill, and classified with an air classifier to obtain toner mother particles with a volume-based average particle size of 8 μm.

[0118] In addition, the volume-based average particle size of the toner base particles was measured with a part...

Embodiment 2~9

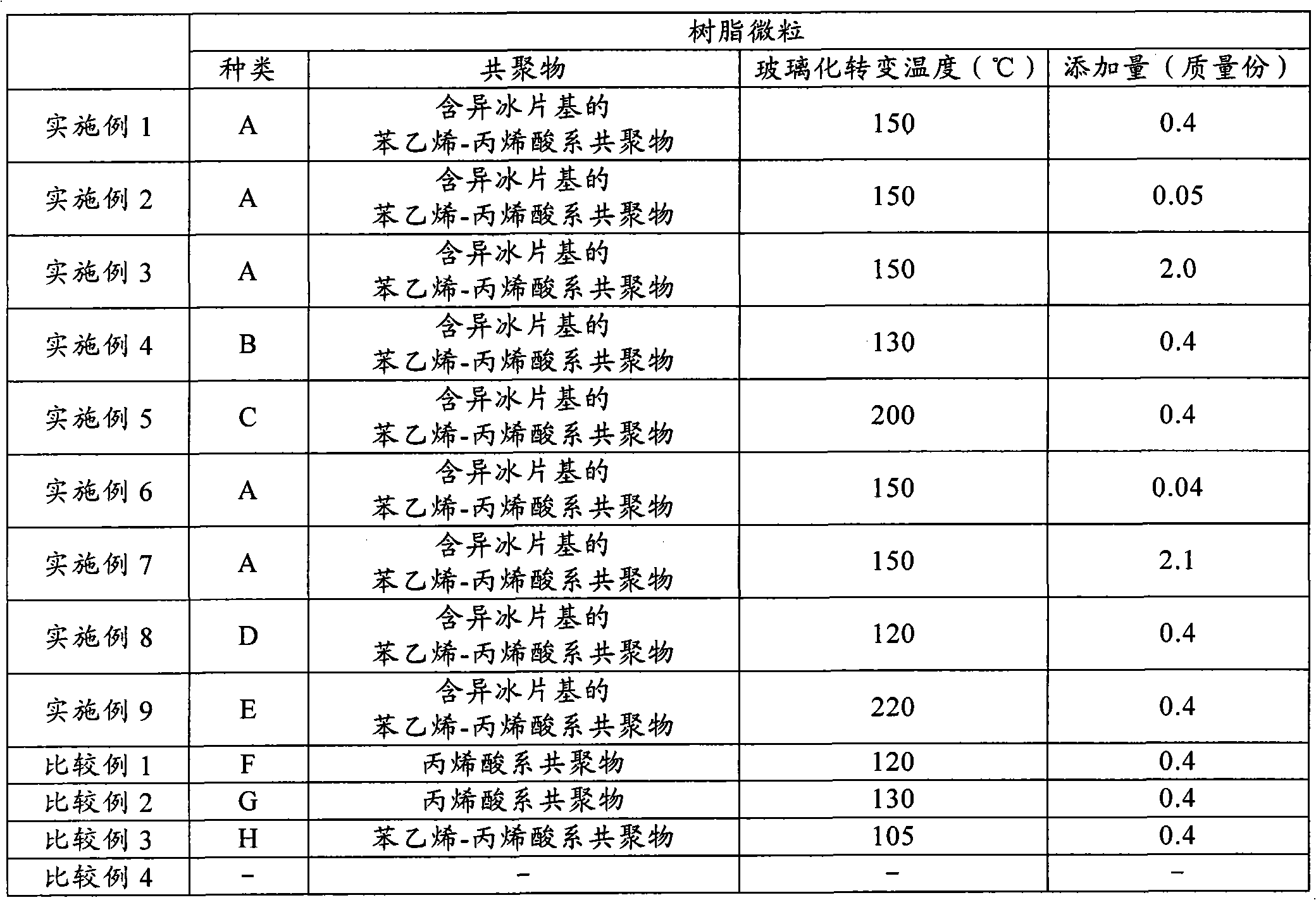

[0132] A two-component developer was prepared in the same manner as in Example 1 except that the type and amount of the resin fine particles were changed as shown in Table 1, and various evaluations were performed. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com