Sample processing method for observing nuclear silver-indium-cadmium control rod metallographic structure

A technology for metallographic structure and sample processing, which is applied in the field of sample processing for observing the metallographic structure of nuclear-grade silver-indium-cadmium control rods, and achieves the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

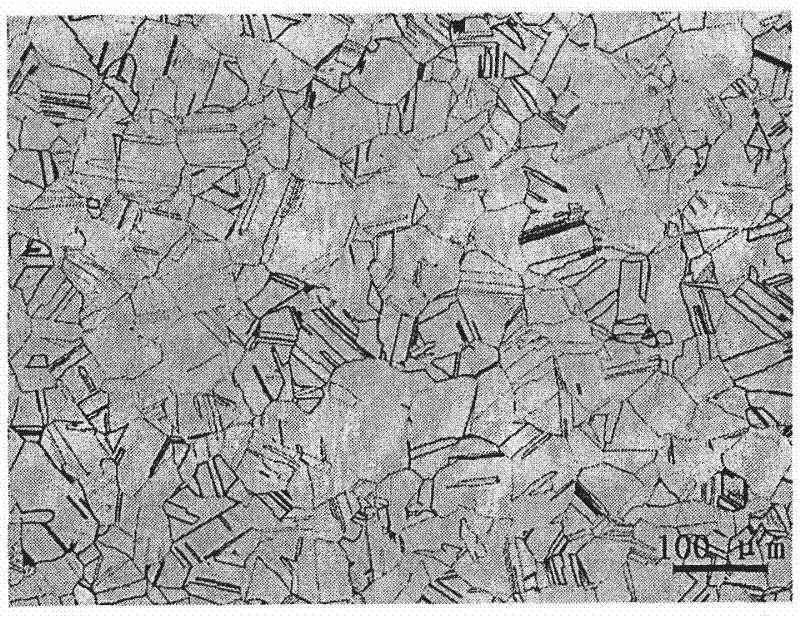

[0017] For nuclear-grade silver-indium-cadmium control rod material samples with a specification of Φ6, a plane is machined first, and then 150 # , 700 # , 1000 # The metallographic water sandpaper is used for grinding, and the ground sample is rinsed with clean water, and then polished on a polishing machine. The samples after polishing are selected from 100mlK 2 Cr 2 o 7 Saturated solution, 1mlH 2 SO 4 Reagent consisting of 1 ml saturated NaCl solution with H 2 After O is mixed, wipe the sample, the mixing volume ratio is 1:6, and the wiping time is 2S. After the erosion is completed, the NaOH solution with a mass percentage concentration of 5% is used to wipe the sample, and the wiping time is 2S. Finally, a clear metallographic structure of nuclear-grade silver-indium-cadmium control rod samples was observed, see figure 1 .

Embodiment 2

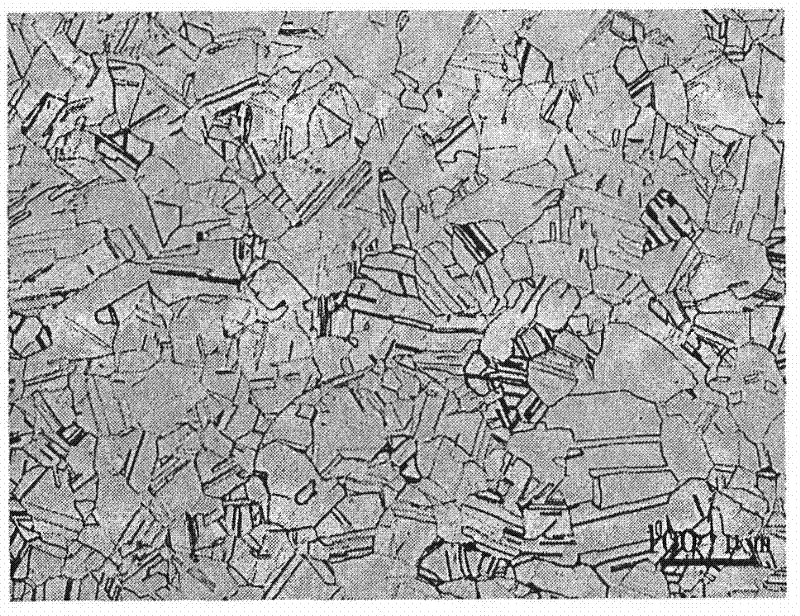

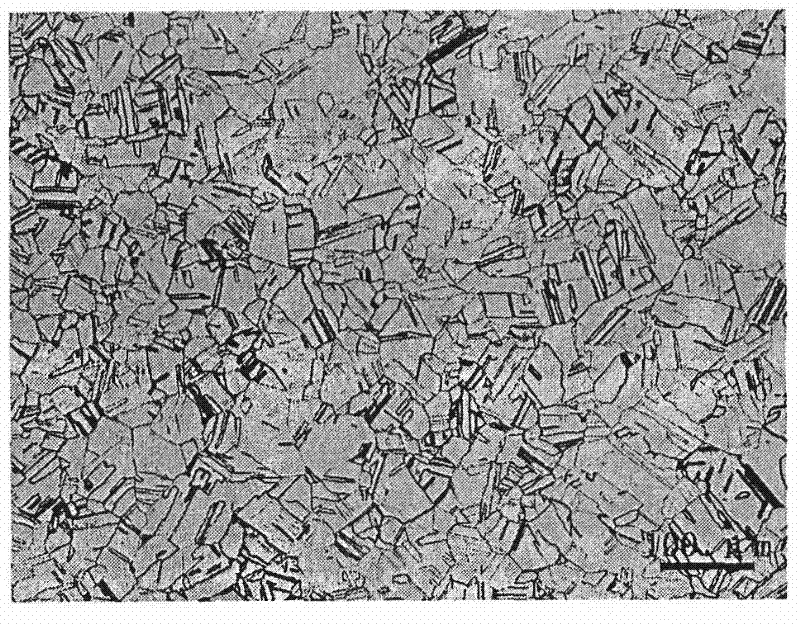

[0019] For nuclear-grade silver-indium-cadmium control rod material samples with a specification of Φ7, a plane is machined first, and then 150 # , 700 # , 1000 # Metallographic water sandpaper is used for grinding step by step, and the ground sample is rinsed with clean water, and then polished on a polishing machine. The sample after polishing is selected from 100mlK 2 Cr 2 o 7 Saturated solution, 3mlH 2 SO 4 Reagent consisting of 2 ml saturated NaCl solution with H 2 After O mixing, wipe the sample, the mixing volume ratio is 1:8, and the wiping time is 4S. After the erosion is completed, the NaOH solution with a mass percentage concentration of 6% is used to wipe the sample, and the wiping time is 3S. Finally, a clear metallographic structure of nuclear-grade silver-indium-cadmium control rod samples was observed, see figure 2 , image 3 .

Embodiment 3

[0021] For nuclear-grade silver-indium-cadmium control rod material samples with a specification of Φ10, a plane is machined first, and then 150 # , 700 # , 1000 # Metallographic water sandpaper is used for grinding step by step, and the ground sample is rinsed with clean water, and then polished on a polishing machine. The sample after polishing is selected from 100mlK 2 Cr 2 o 7 Saturated solution, 5mlH 2 SO 4 Reagent consisting of 3 ml saturated NaCl solution with H 2 After O mixing, wipe the sample, the mixing volume ratio is 1:10, and the wiping time is 5S. After the erosion is completed, the NaOH solution with a mass percentage concentration of 10% is used to wipe the sample, and the wiping time is 4S. Finally, a clear metallographic structure of nuclear-grade silver-indium-cadmium control rod samples was observed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com