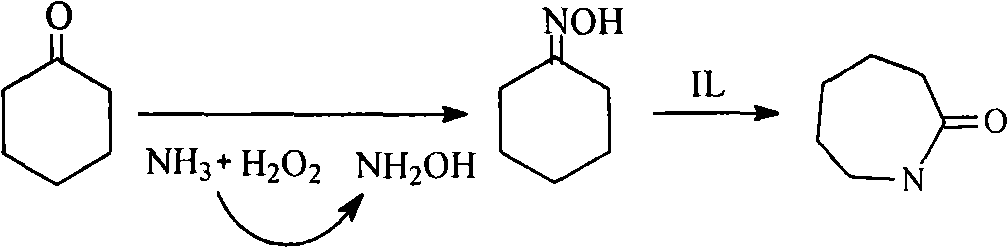

Process for directly synthesizing caprolactam by using cyclohexanone

A technology of caprolactam and cyclohexanone, which is applied in the field of organic chemical synthesis, can solve the problems of intermediate product separation and energy consumption, and achieve the effects of avoiding repeated installation of equipment, no corrosion of equipment, and mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Synthesis of room temperature ionic liquid N,N,N-trimethyl-N-sulfobutyl-ammonium bisulfate (Chinese patent, application number 200710151000.1):

[0025] In the first step, take an aqueous solution of trimethylamine containing 0.5 mol of trimethylamine and 0.5 mol of 1,4-butane sultone, put them in a 250 ml three-necked flask, and stir and react at room temperature for 12 hours.

[0026] In the second step, the reaction solution obtained in the first step is taken out and subjected to rotary evaporation to remove water to obtain a white zwitterionic solid.

[0027] In the third step, the substance obtained in the second step is washed successively with absolute ethanol, toluene and anhydrous ether, and then vacuum-dried to constant weight at 80 ° C to obtain the zwitterion N, N, N-trimethyl-N- sulfobutyl ammonium.

[0028] In the fourth step, take 0.5 mol of the white zwitterionic solid obtained in the third step and put it into a four-necked flask, slowly add 0.5 mol o...

Embodiment 2

[0030] With 0.01mol (1.0g) cyclohexanone and 0.5gTS-1 (Hunan Jianchang Petrochemical Co., Ltd., the specific surface area is 390m 2 / g,TiO 2 The content is 5-10%, SiO 2 The content is 90-95% (mol%)) is placed in a 100ml three-necked flask, and placed in a water bath at 50° C. for magnetic stirring reaction. Slowly add 1.3g mass concentration of 25% ammonia (NH 3 : 0.02mol) and 1.7g mass concentration of 30% hydrogen peroxide (H 2 o 2 : 0.015mol), after reacting for 1.5 hours, add 0.03mol (8.8g) by the room temperature ionic liquid N that embodiment 1 makes, N, N-trimethyl-N-sulfobutyl-ammonium bisulfate, after 10 minutes Stop responding. Extract twice with 5ml of dichloromethane, combine the extracts, and analyze the extracts directly on a gas chromatograph. The result of the reaction is that the conversion rate of cyclohexanone is 39.4%, the selectivity of caprolactam is 91.3%, and the selectivity of by-product cyclohexanone oxime is 8.7%.

Embodiment 3

[0032] The steps are the same as in Example 2, except that 0.01 mol (2.9 g) of the room temperature ionic liquid N,N,N-trimethyl-N-sulfobutyl-ammonium hydrogen sulfate prepared in Example 1 is added. The result of the reaction is that the conversion rate of cyclohexanone is 56.8%, the selectivity of caprolactam is 91.2%, and the selectivity of by-product cyclohexanone oxime is 8.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com