Modular and standardized small LNG gasifying station and design method thereof

A gasification station and modularization technology, applied in the field of LNG gasification station, can solve the problems of complicated design work and many factors to be considered in the design, and achieve the effect of facilitating subsequent planning and construction, optimizing valve settings, and avoiding repeated settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

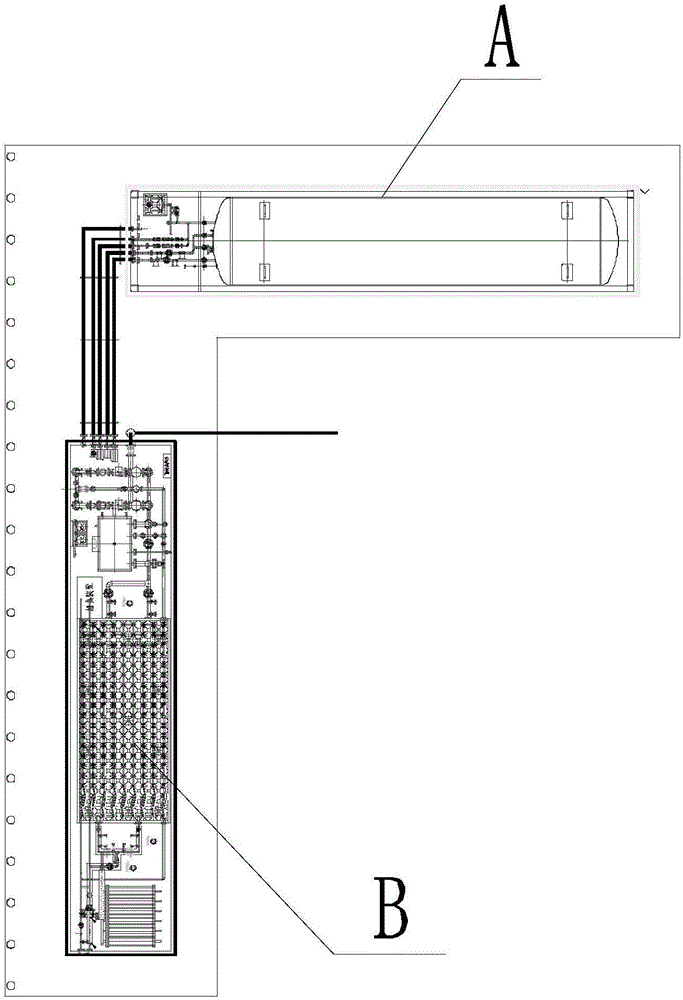

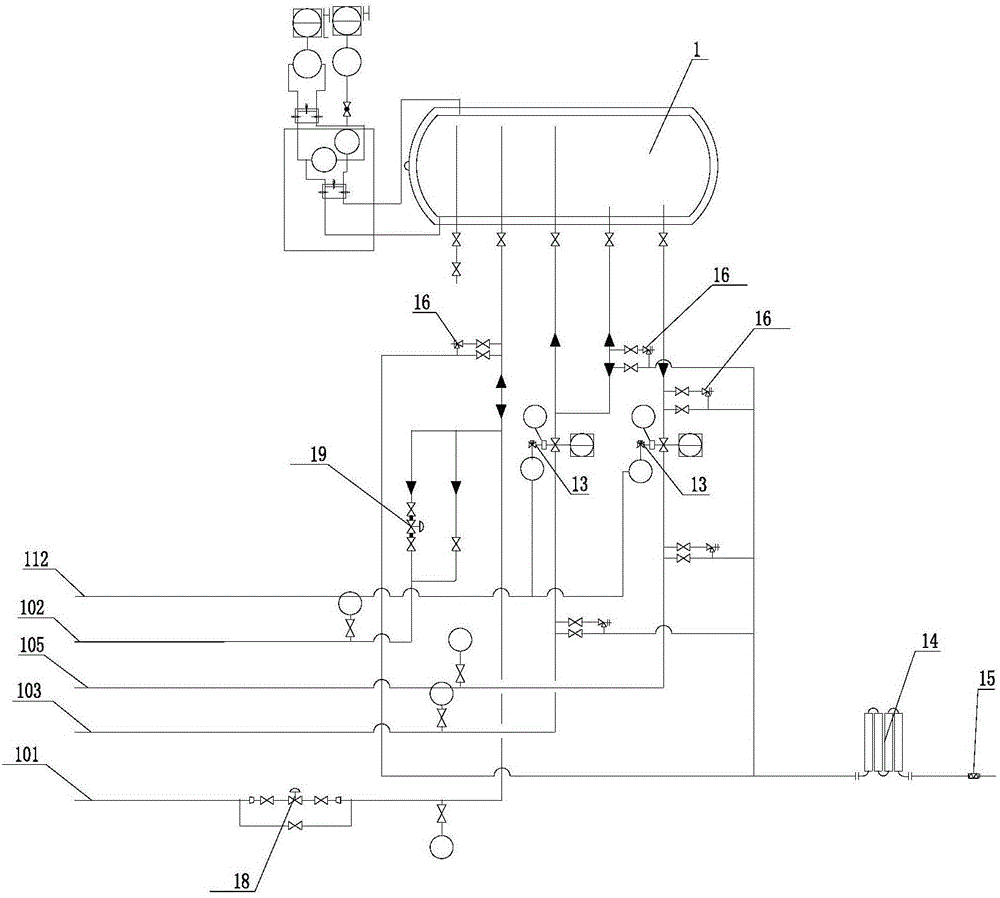

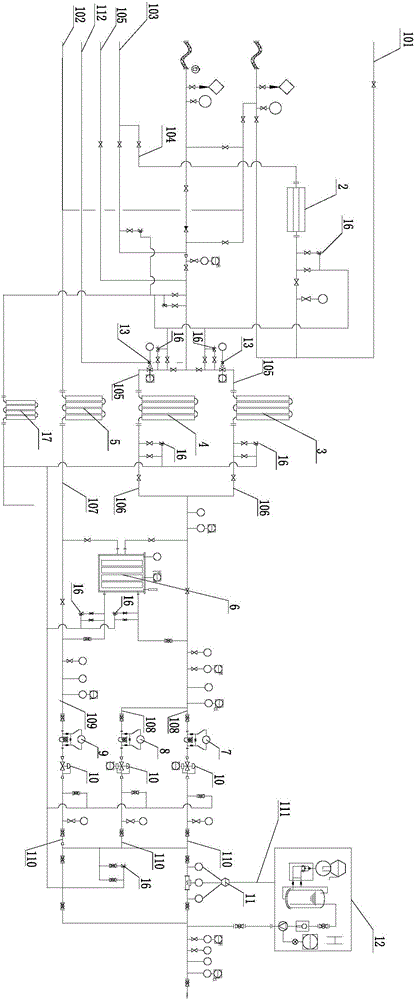

[0062] combine Figure 1 to Figure 3 , which describes a specific embodiment of the present invention in detail, but does not limit the claims of the present invention in any way.

[0063] Design a modular and standardized small-scale LNG gasification station, whose technical index is that the volume of a single LNG storage tank is 20m 3 , The gasification capacity is 800m 3 / h. The specific design steps are:

[0064] (1) Design the LNG gasification process flow. According to the LNG gasification process flow, the gasification station is divided into 4 modules for design. The 4 modules are: control system module, LNG storage tank skid module, unloading gasification pressure regulation measurement Skid module and connecting pipeline module, the LNG gasification process is:

[0065] A. Tanker unloading, the liquid outlet pipe of the tanker passes through the pipeline to the upper liquid inlet pipe and the lower liquid inlet pipe of the LNG storage tank, and the LNG liquid en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com