Processing method for produced water for ultra-low permeable oil field reinjection

A treatment method and produced water technology, which are applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem that the suspended solids content and the median particle size of the effluent water quality cannot meet the requirements. , complex operation and high cost, to achieve the effect of prolonging service life, high biochemical reaction efficiency and reducing operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

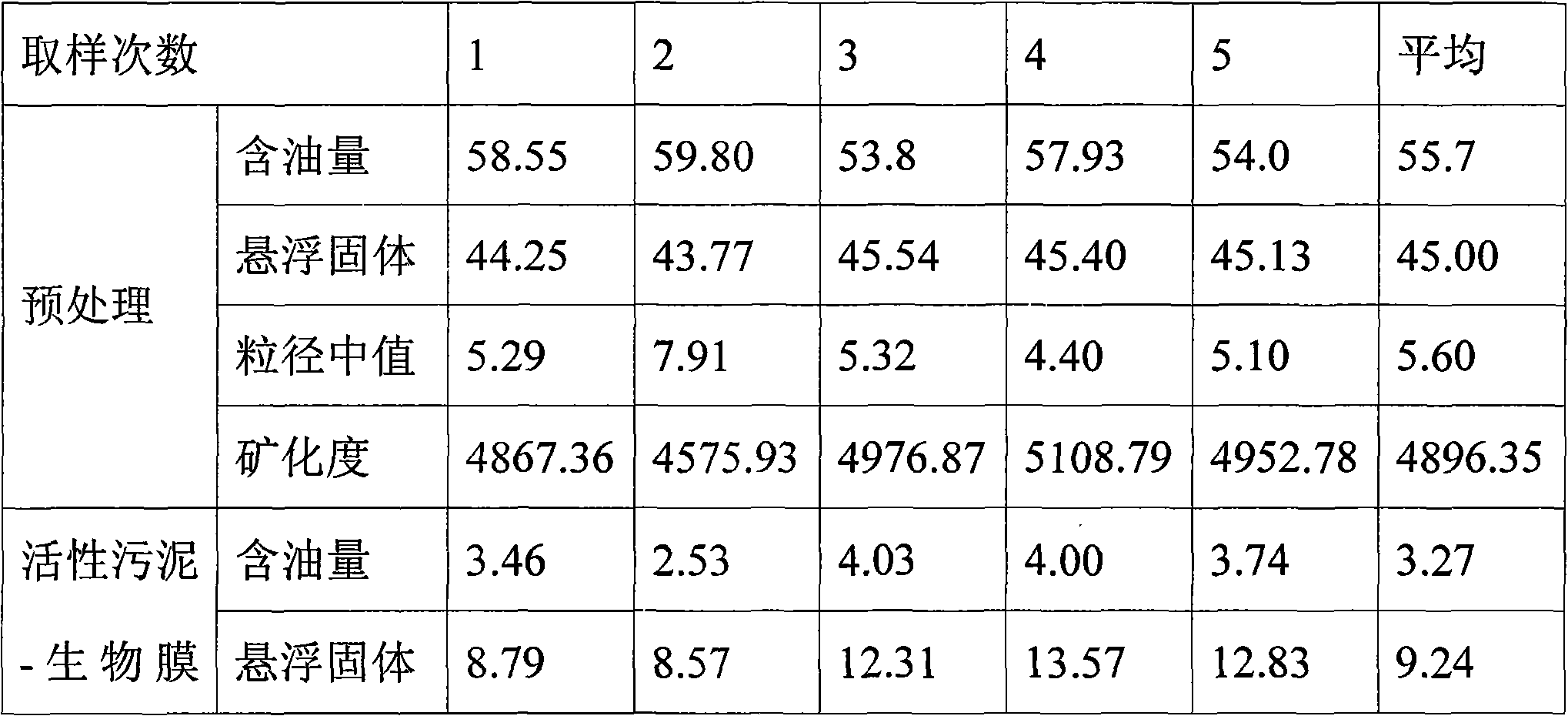

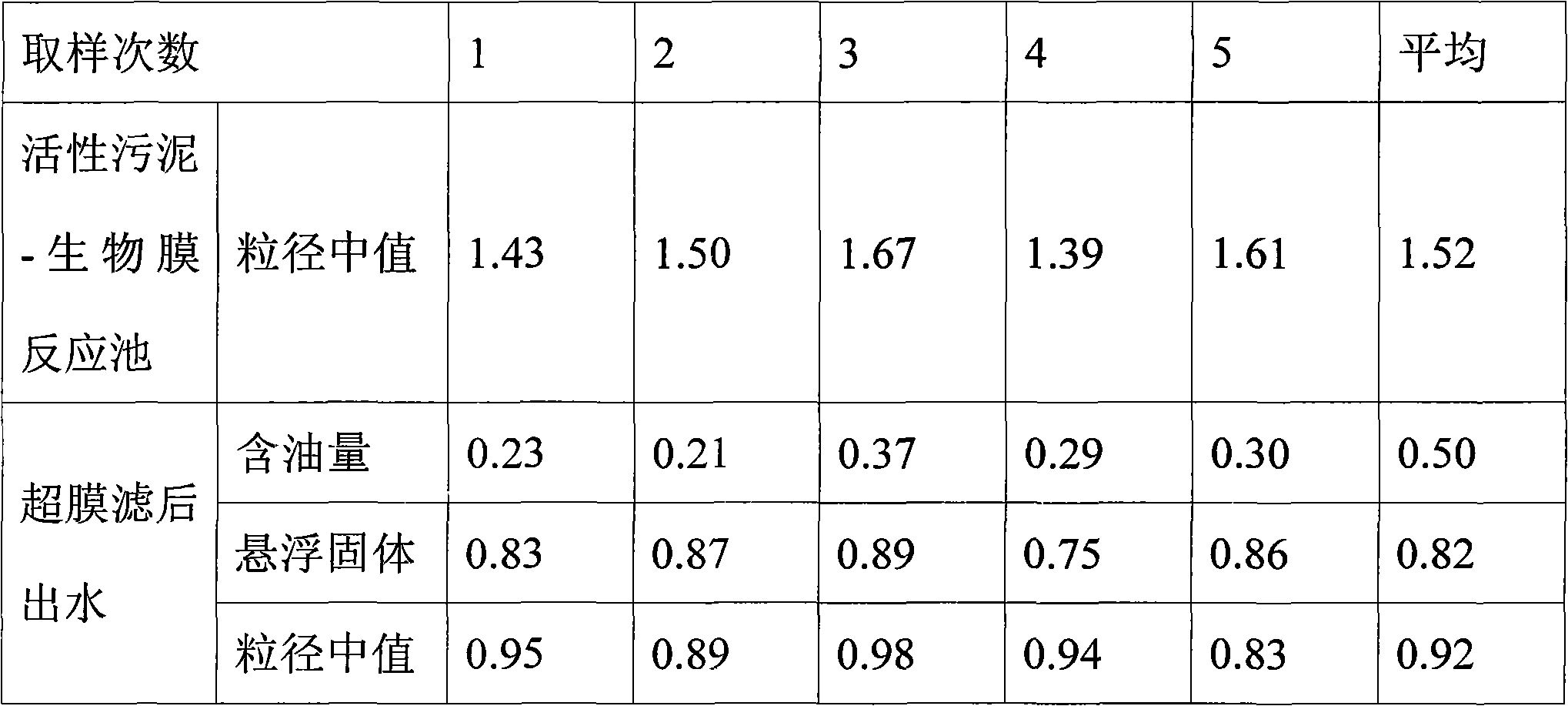

[0010] Specific embodiment one: the processing of the produced water for reinjection in the ultra-low permeability oil field in this embodiment is realized according to the following steps: 1. Add coagulant or flotation agent to the produced water of the oil field to be treated, and carry out coagulation and sedimentation treatment to obtain Supernatant; 2. The pH value of the supernatant is 6-9, the temperature is 15-40°C, the salinity is 4000-6000mg / L, the suspended solid content is 30-60mg / L, and the suspended solid particle size is 0.1~10μm, oil content 30~150mg / L, COD Cr Under the condition of 300-600mg / L, it is passed into the activated sludge-biofilm reaction tank, and the hydraulic retention time is 6-10h; 3. The oilfield produced water treated in step 2 is passed into the sedimentation tank for sedimentation treatment, and then After passing through a 0.001-0.02 μm ultrafiltration membrane, the treatment of the produced water for reinjection in the ultra-low permeabil...

specific Embodiment approach 2

[0011] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the activated sludge-biofilm in the step two activated sludge-biofilm reaction tank adopts the following methods to domesticate and obtain: a, to the activated sludge-biofilm reaction tank Add filler in the middle, the volume of filler is 18%~28% of the volume of activated sludge-biofilm reaction tank; b, sludge is added into activated sludge-biofilm reaction tank; c, domestication culture; Wherein step b uses The concentration of sludge in the activated sludge-biofilm reaction tank is 3000-5000mg / L. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0012] Specific embodiment 3: The difference between this embodiment and specific embodiment 2 is that the volume of the filler in step 1a is 24% of the volume of the activated sludge-biofilm reaction tank. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com