Hot-pressing system for manufacturing board by utilizing crop straws

A technology of crop straw and heating system is applied in the field of processing equipment to achieve the effects of eliminating constraints, high stability and reliability, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

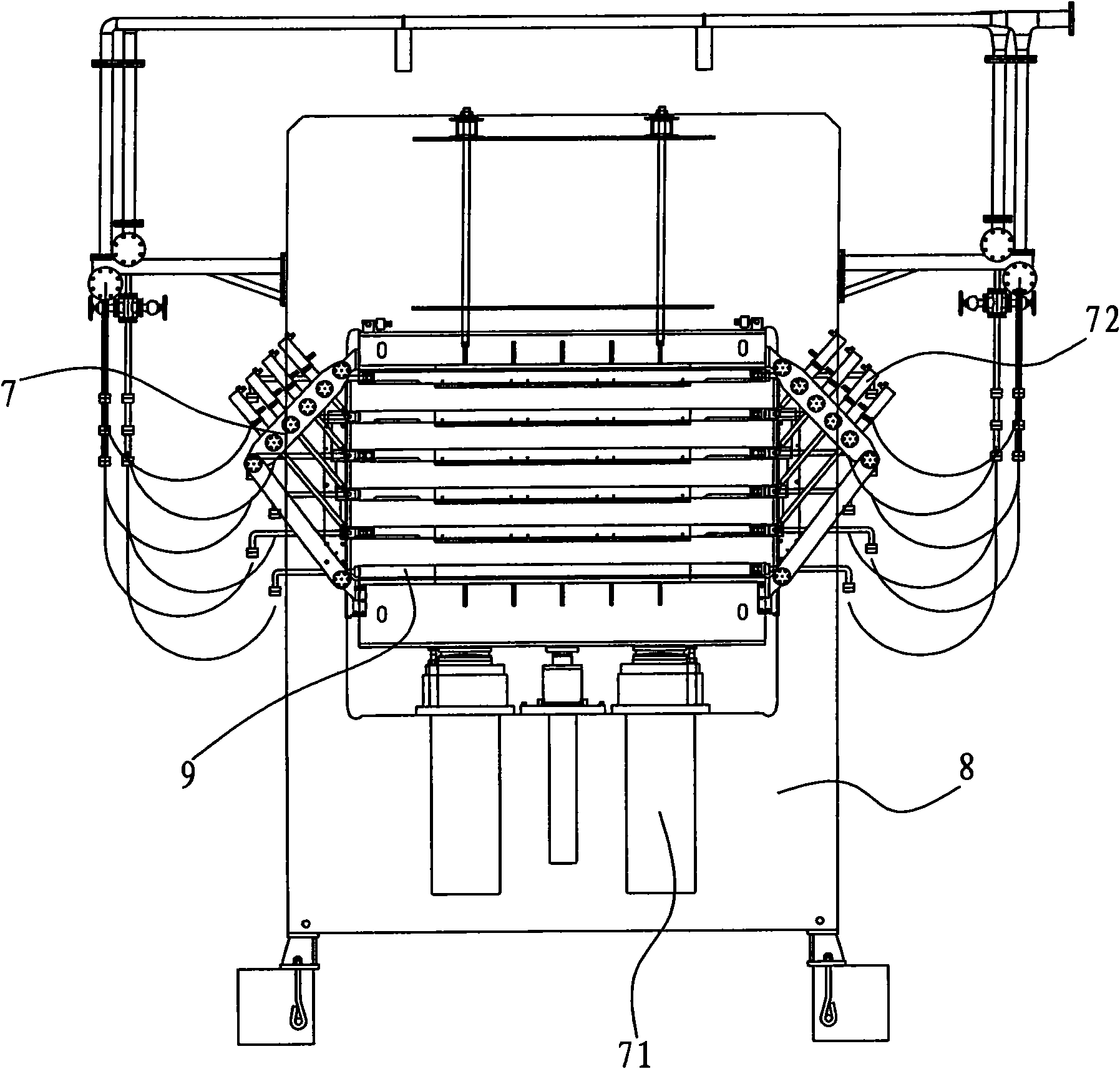

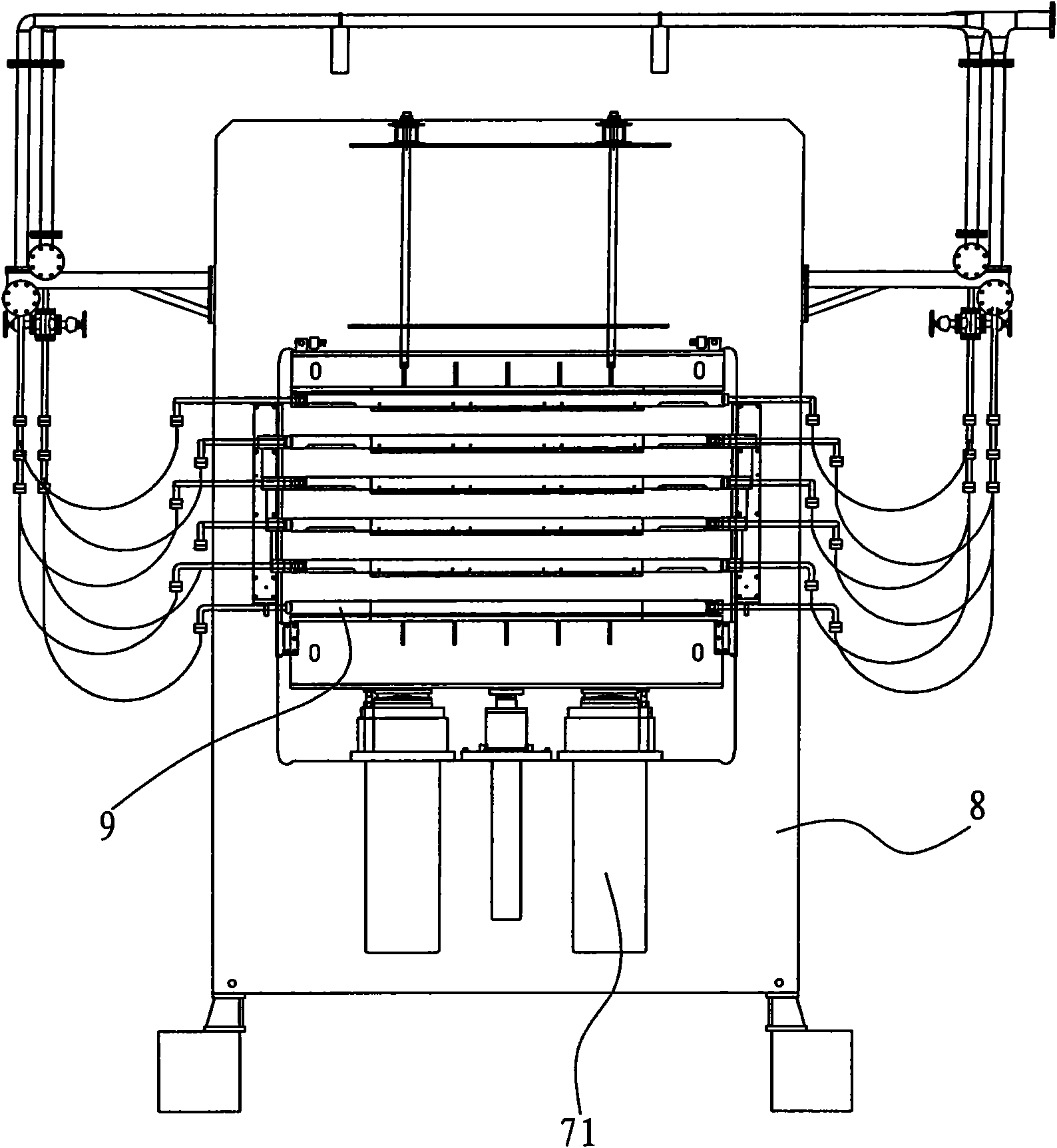

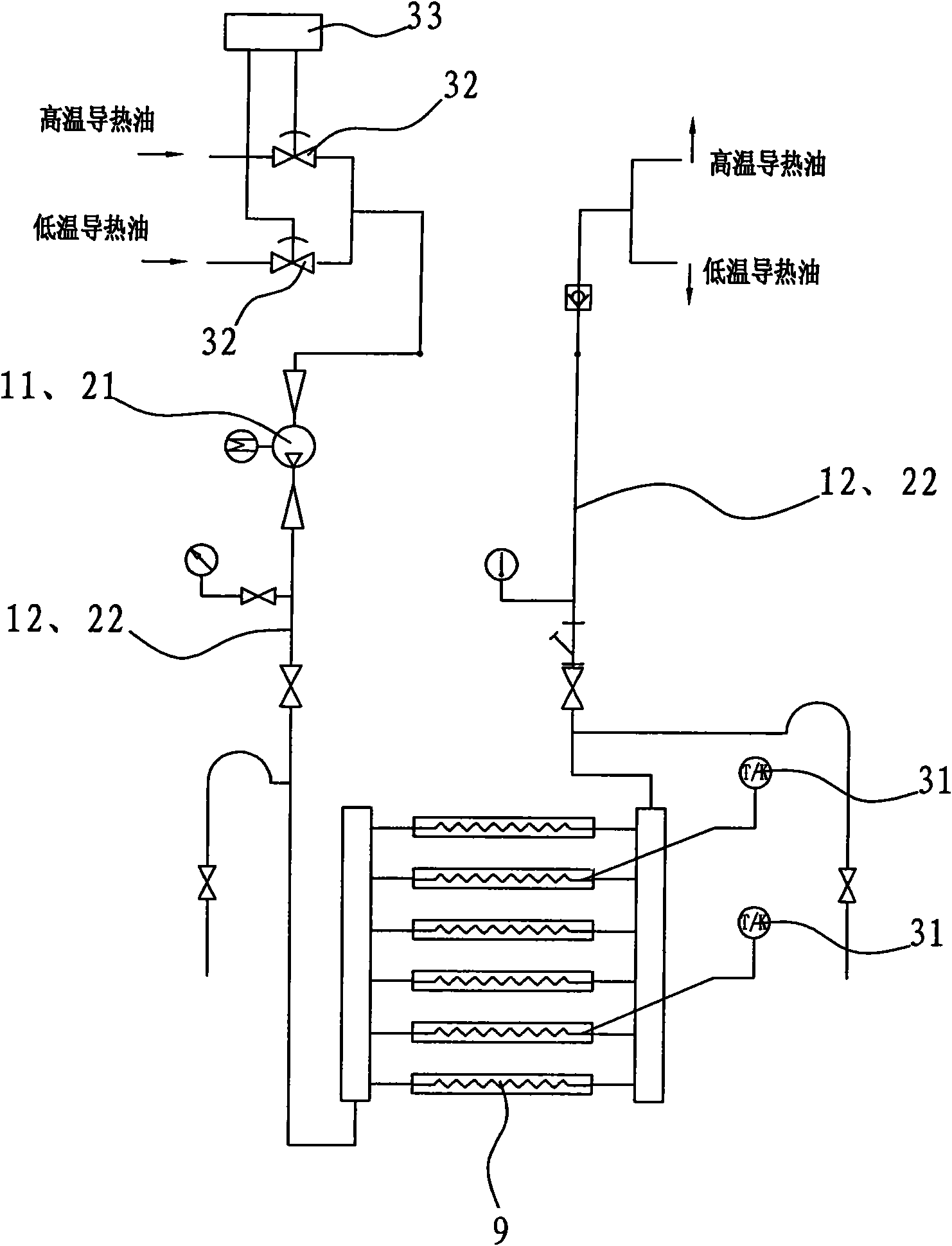

[0028] In order to better illustrate the principles and advantages of the present invention, firstly, the hot-pressing process for making boards from crops will be described in detail.

[0029] When the slab enters the hot-pressing system, the hot-pressing plate begins to transfer heat energy directly to the slab through the surface of the slab. Due to the physical properties of the raw material, these heat transfer processes require different heating rates depending on the thickness of the slab. During the heat conduction process, since the surface layer of the slab is in contact with the hot plate of the press and the metal backing plate, its surface layer is quickly heated. Although the surface layer of the board can quickly reach the temperature of the hot-pressed board, the heat conduction effect of the plant fiber itself is very poor, and the heat of the hot-pressed board cannot penetrate into the core layer of the slab. The core layer of the slab is thus maintained at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com