Vacuum distilling apparatus for easy-curing material

A distillation device and material technology, applied in vacuum distillation and other directions, can solve the problems of material failure to update in time, burning motor, affecting distillation process, etc., and achieve the effect of stable, reliable and continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

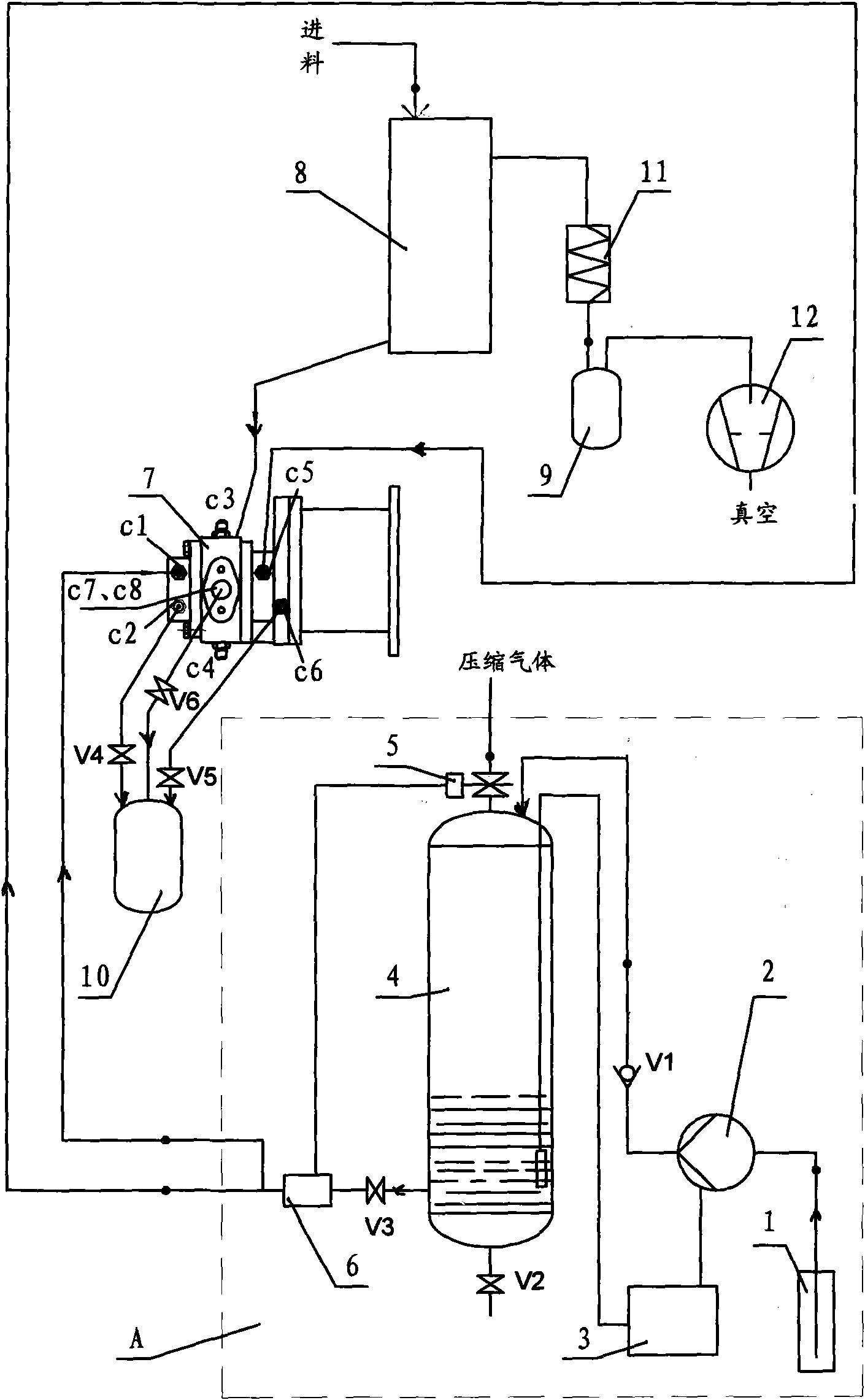

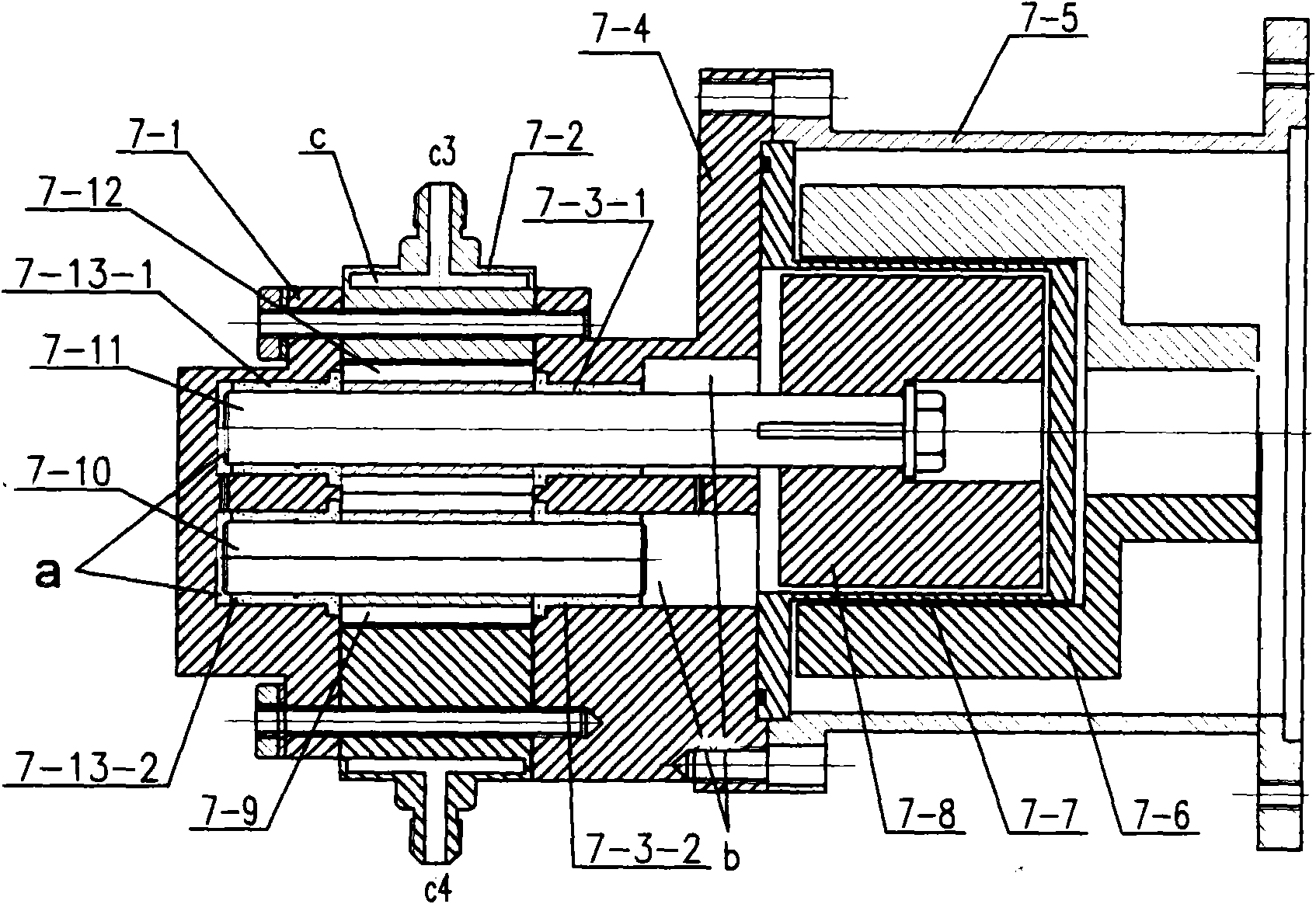

[0015] Such as figure 1 As shown, the vacuum distillation device is according to figure 1 Installed and connected with pipelines, it is composed of evaporator 8, low boiling point liquid storage tank 9, discharge pump 7, high boiling point material liquid storage tank 10, and a set of liquid pressurizing device A, and the liquid pressurizing device A is composed of a Liquid pressure storage tank 4, mass flow meter or weighing module capable of measuring mass flow rate 6, three-way pressure automatic adjustment control valve 5, liquid level controller 3, positive displacement pump 2 and solvent storage tank 1. The inlet of the positive displacement pump 2 is inserted into the solvent storage tank 1 through a pipeline, and the outlet of the positive displacement pump 2 is connected to the liquid pressure storage tank 4 through a pipeline, and a check valve V1 is installed on the pipeline; the liquid level controller 3 passes through the control line It is connected with the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com