Refuse derived fuel (rdf) pyrolysis gasification system

A waste-derived fuel, pyrolysis and gasification technology, applied in the manufacture of combustible gas, incinerators, combustion methods, etc., can solve the problems of secondary pollution of soil and water sources, high investment in urban waste treatment, and insufficient publicity, and achieve convenient Centralized management and control, saving material and personnel costs, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the drawings:

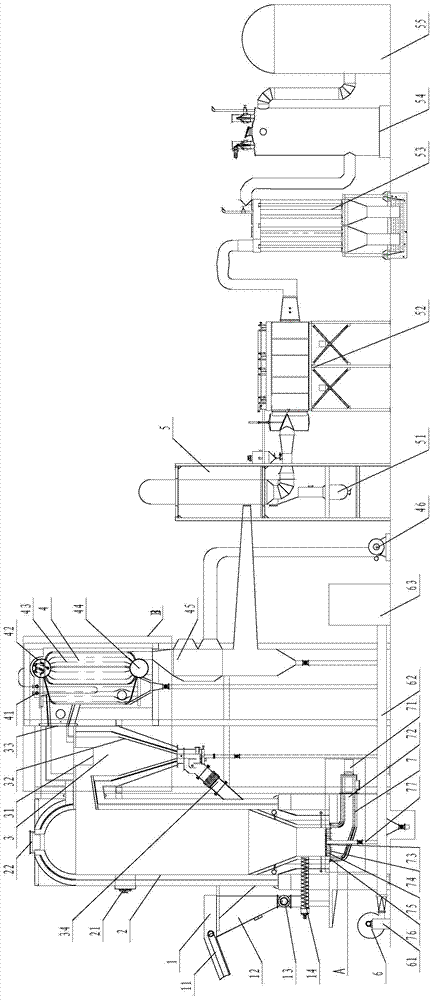

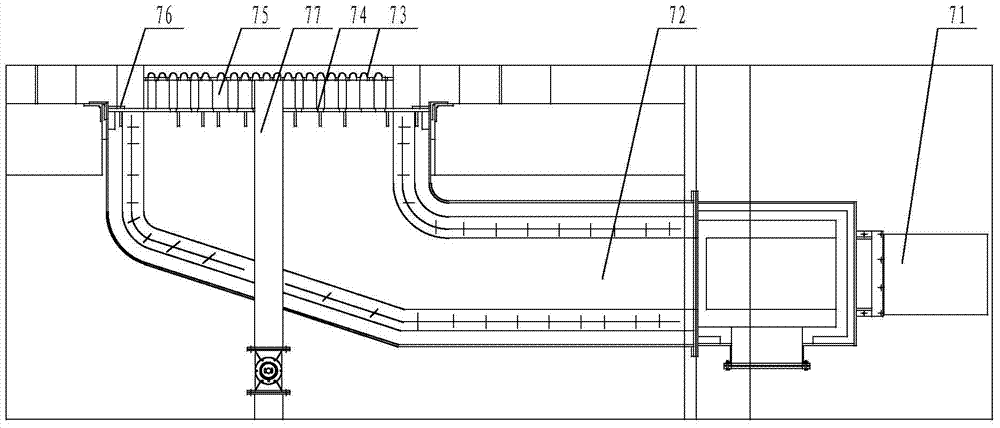

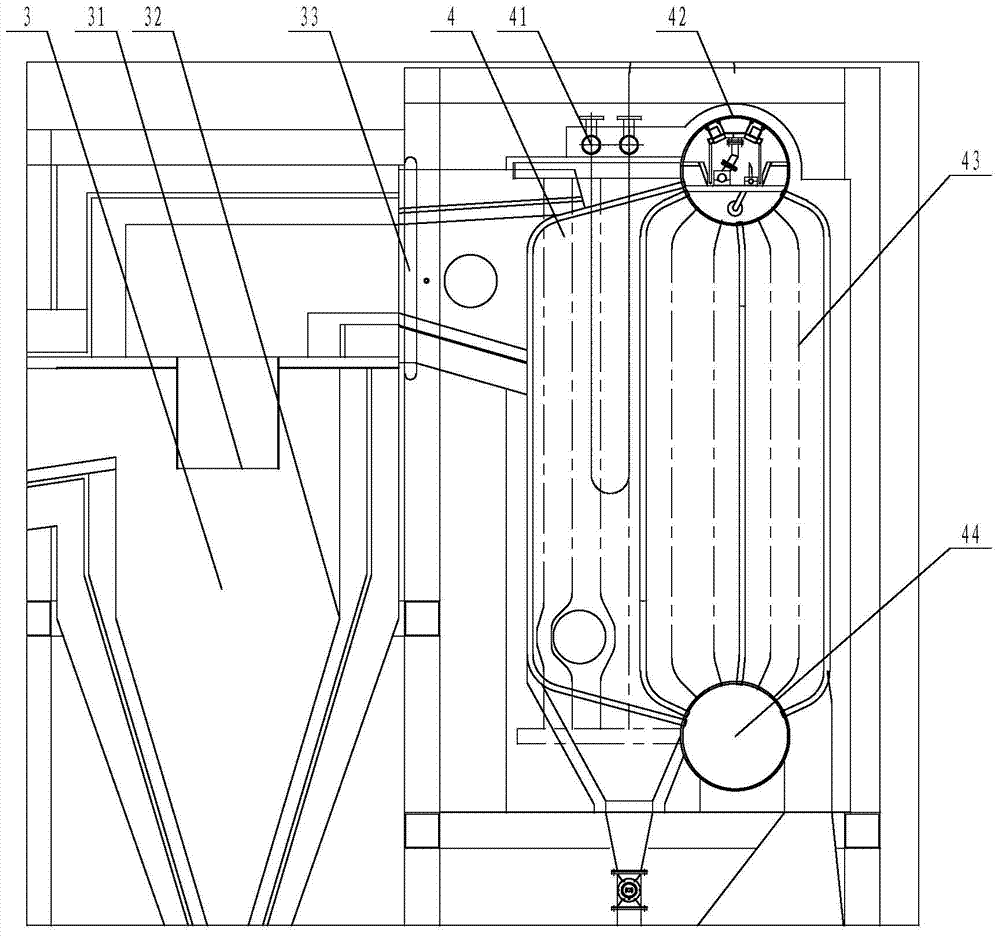

[0026] Such as figure 1 As shown, the refuse-derived fuel (RDF) pyrolysis and gasification system includes a feed device 1, a waste heat boiler 4 and a cold slag system 6, a pyrolysis gasifier 2, a high-temperature separator 3 and a pyrolysis gas purification system 5. The bottom of the degasification furnace 2 is provided with a boiling fluidized bed 7; the feeding device 1 is connected to the pyrolysis gasification furnace 2, which is connected to the waste heat boiler 4 through the high temperature separator 3, and the slag cooling system 6 Connected to the slag discharge device of the pyrolysis gasifier 2 and the waste heat boiler 4 respectively;

[0027] The feeding device 1 includes a furnace front hopper 12 and a screw pusher 14. The screw pusher is formed by fully enclosed welding. A star-shaped closed feeder 13 is provided between the furnace front hopper 12 and the screw pushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com