Ammonia sensing material

A technology of ammonia gas and dyes, which is applied in the direction of using chemical indicators for analysis, etc., can solve problems such as machine damage, influence on semiconductor technology, and operator injury, and achieve cost savings, improve detection sensitivity and speed, and improve detection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of ammonia gas sensing material of the present invention comprises the following steps:

[0025] (a) First prepare the initial solution, dissolve the required sodium metasilicate (sodium metasilicate) in deionized water, and then stir the solution evenly.

[0026] (b) Then prepare a strong acid (such as sulfuric acid, hydrochloric acid) solution and slowly drop it into the above solution to control the pH value of the solution to about 9-11. At this time, the solution will form a gel.

[0027] (c) Then prepare a surfactant, such as cetyltrimethylammonium bromite (CTAB), weigh the required surfactant and add it to deionized water for stirring. After stirring, slowly drop it into the pre-step In the solution, when the surfactant is dropped, the solution will have a flocculation phenomenon. The role of the surfactant is to provide a template for the preparation of mesoporous materials.

[0028] (d) After stirring for 3 hours, put the solution into ...

Embodiment 1

[0035] Example 1: Preparation of ammonia sensing material containing silicate mesopore material

[0036] Weigh 21.2g of sodium metasilicate (sodium metasilicate) into 80mL of deionized water and stir for 30 minutes, then prepare a 4N sulfuric acid (sulfuric acid98%) solution and slowly drop it in to control the pH value of the solution to 10.5. At this time, the solution will form a gel shape. Then configure the surfactant cetyltrimethylammonium bromite (cetyltrimethylammonium bromite, CTAB), weigh CTAB 7.2g and add 25mL of deionized water to stir, after stirring, slowly drop into the pre-step solution, in the drop When CTAB is added, the solution will flocculate. After stirring for 3 hours, the solution was placed in a pressure cooker and placed in an oven, and synthesized by a hydrothermal method at 145° C. for 36 hours. Take it out from the oven, let it cool down, and perform suction filtration, and rinse it several times with deionized water, then take out the filter cak...

Embodiment 2

[0038] Example 2: Preparation of ammonia sensing material containing aluminosilicate mesopore material

[0039] The synthesis method of porous materials in aluminosilicates with different silicon / aluminum ratios, first weigh the required sodium metasilicate (sodium metasilicate) and add 80mL of deionized water, the sodium metasilicate required for different silicon / aluminum ratios As shown in Table 1, add the required aluminum sulfate (aluminum sulfate) into 20mL deionized water, mix the seed solution and stir for 30 minutes. Change to 10 hours.

[0040] Table 1

[0041] Silicon / aluminum ratio Added aluminum sulfate weight (g)

[0042] 25 0.684

[0043] 50 0.342

[0044] 75 0.228

[0045] 100 0.171

[0046] 150 0.114

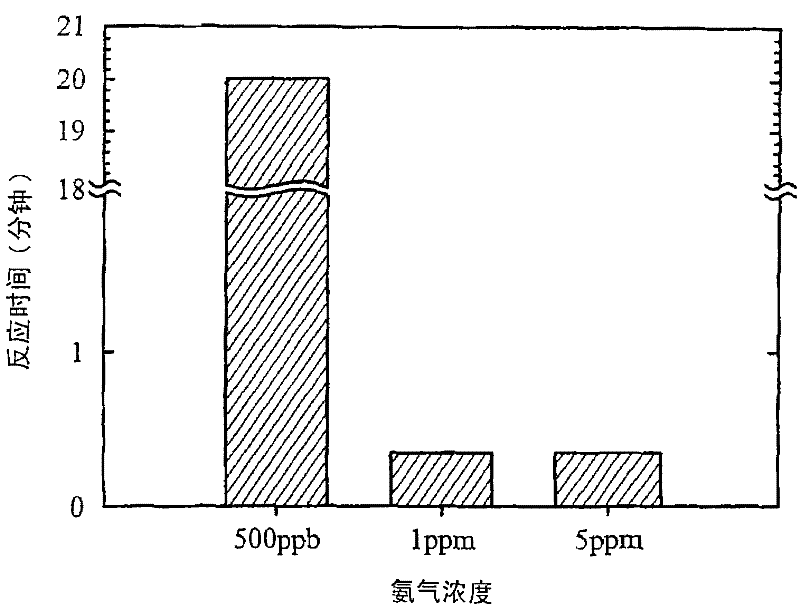

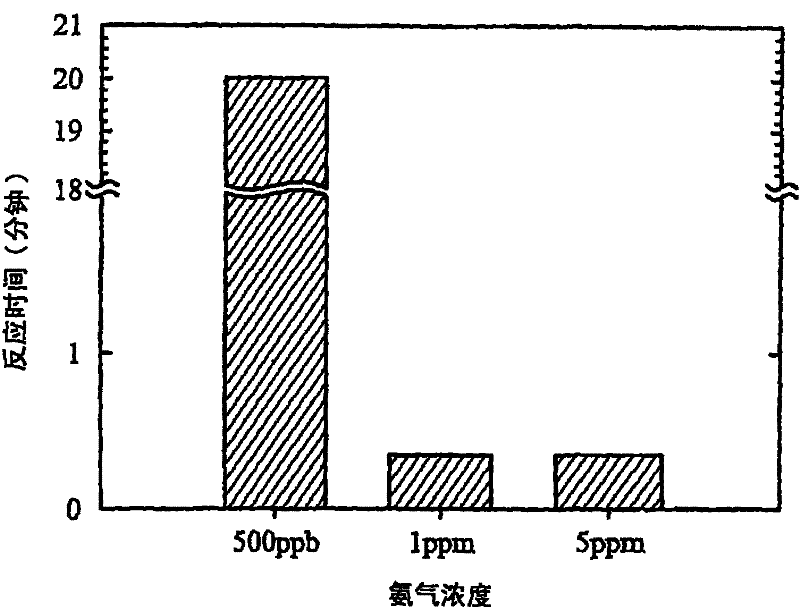

[0047] Then measure 0.3 g of different silicon-aluminum ratios of aluminosilicate mesoporous materials and 0.001 g of indicator bromocresol green (b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com