Electroplating amorphous ferrum-nickel-tungsten alloy corrosion-resistant wear-resistant oil pump

An anti-corrosion and wear-resistant, amorphous iron technology, used in pumps, mechanical equipment, liquid variable capacity machinery, etc., can solve the problems of hexavalent chromium environmental pollution, general wear resistance, environmental pollution, etc., and achieve environmental protection treatment. Low cost, good bonding force and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

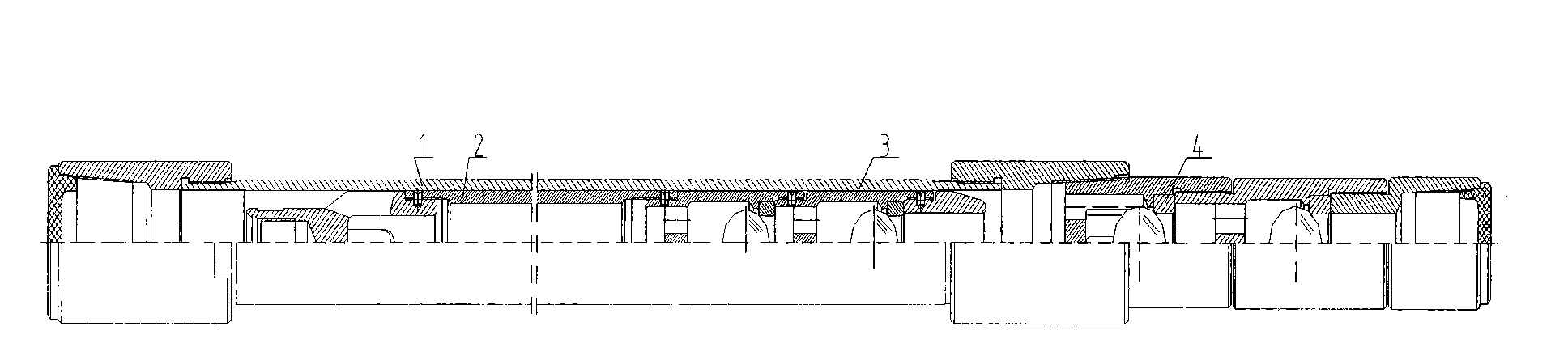

[0010] Such as figure 1 As shown, the present invention is an electroplated amorphous iron-nickel-tungsten alloy anti-corrosion and wear-resistant oil well pump. The main structure includes a pump barrel 1, a protective layer 2, a plunger 3 and an oil inlet valve 4, wherein the upper end of the plunger is connected to the oil outlet cover. The lower part is equipped with an oil outlet valve.

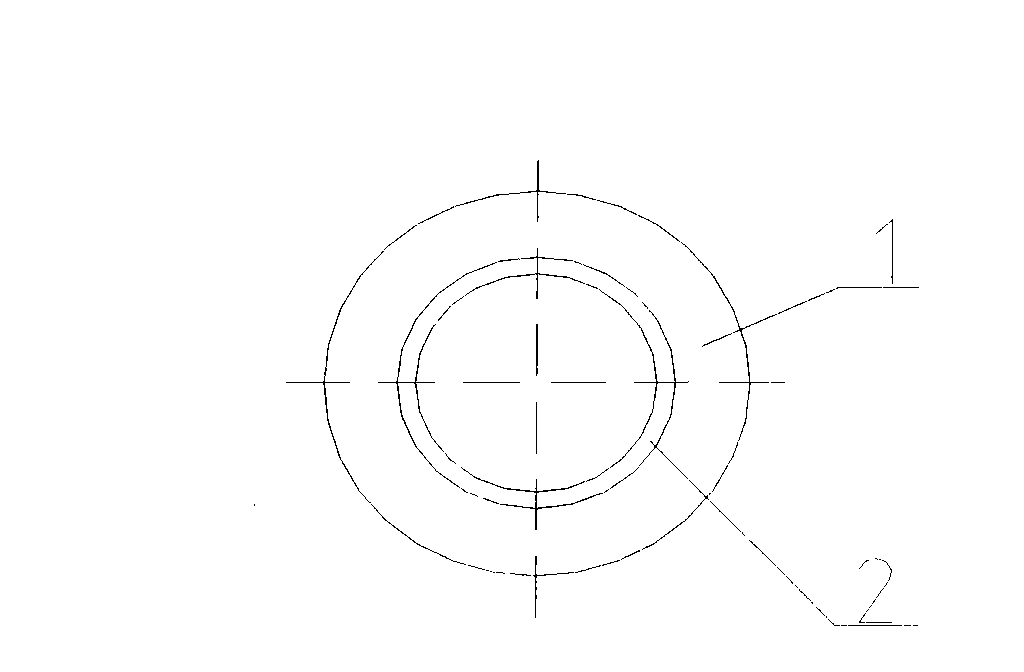

[0011] Refer to attached figure 2 A layer of amorphous iron-nickel-tungsten anti-corrosion and wear-resistant protective layer 2 is plated on the inner surface of the pump barrel 1, and the thickness of the protective layer is not less than 75 μm.

[0012] The electroplating process flow of the pump barrel 1 of the oil well pump is: electrolytic degreasing-clean water cleaning-etching-deionized water cleaning-electroplating-water washing-heat treatment. Electrolytic degreasing is treated in a degreasing liquid at 70°C for 5-10 minutes, and the current density is 5-10A / dm 2 ; Etching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com