Diesel oil cold filter clogging temperature improving agent and preparation method thereof

A cold filter point and improver technology, which is applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of cold filter point rebound and rebound, and achieve the effect of preventing rebound rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

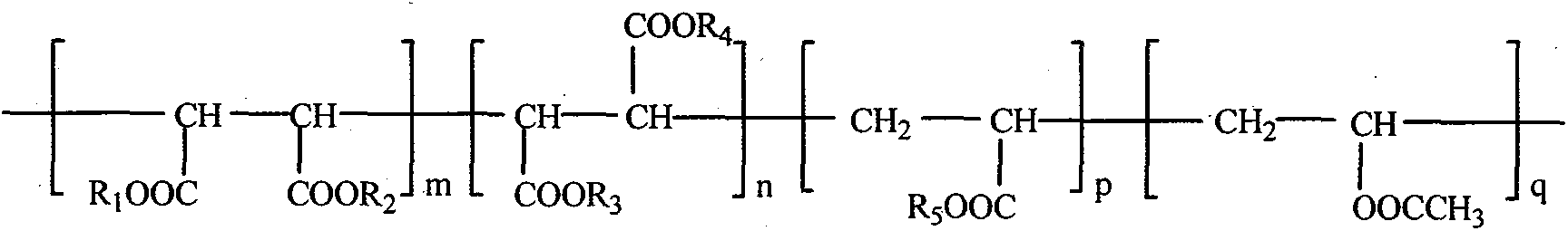

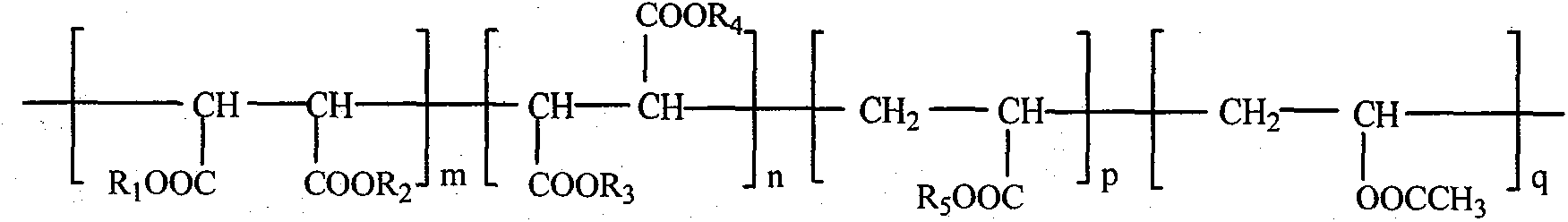

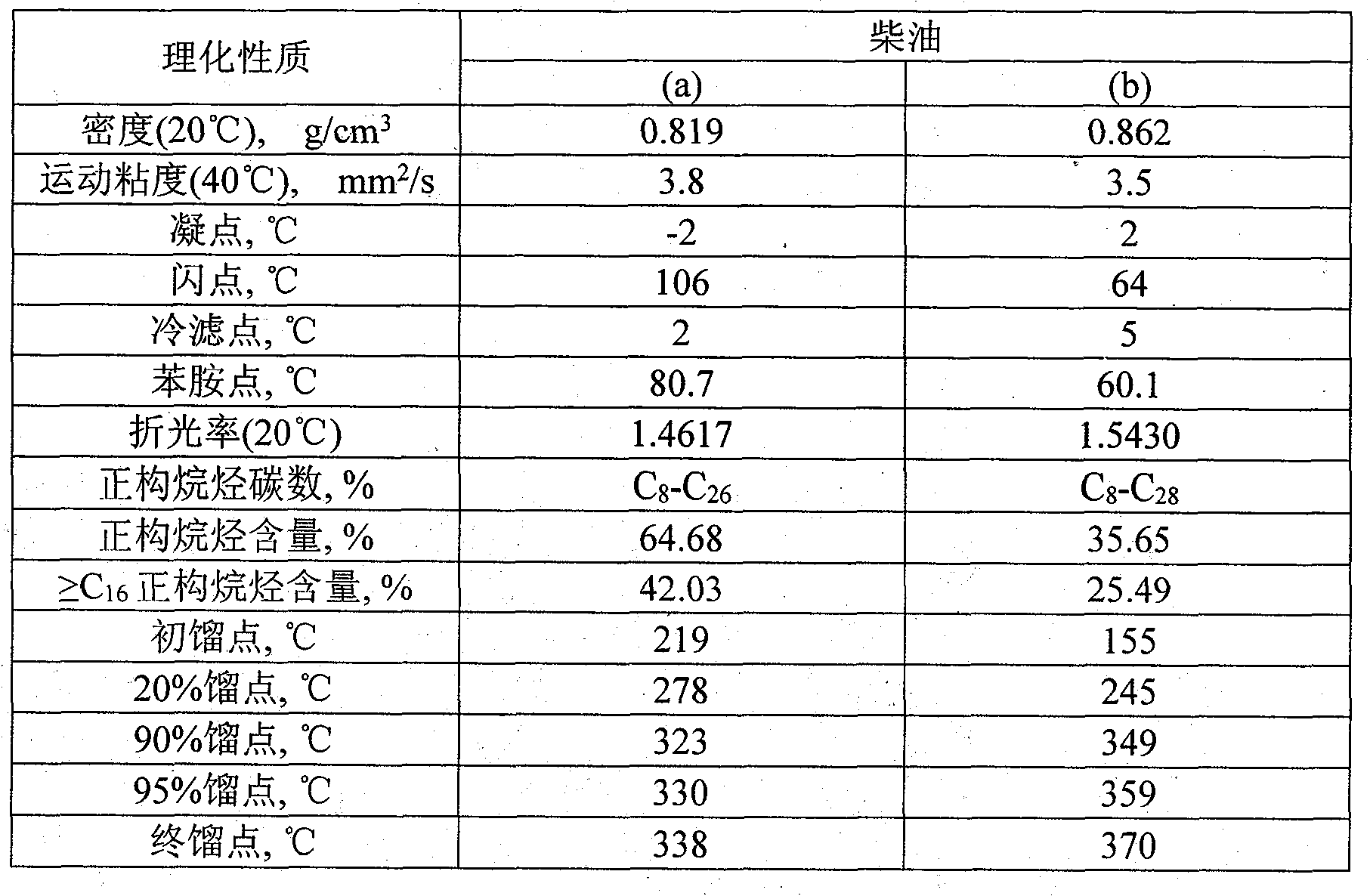

Method used

Image

Examples

example 1

[0023] This example is the preparation of a diesel oil cold filter point improver

[0024] Put 0.01mol maleic acid mixed alcohol ester, 0.01mol fumaric acid mixed alcohol ester, 0.04mol vinyl acetate and 60g toluene in a container equipped with an electric stirrer, a thermometer, a reflux condenser, and a nitrogen gas introduction tube In the reactor, feed nitrogen for 15-30 minutes, and maintain a weak nitrogen flow during the reaction, heat and stir, and raise the temperature to 40-60°C, add 0.16g composite initiator, 0.04mol mixed alcohol acrylate, and heat up to 70 ~90°C, keep warm for 4-6 hours. The composite initiator is composed of benzoyl peroxide and azobisisobutyronitrile in a mass ratio of 1:0.6. Then, the tetrapolymer was obtained through vacuum distillation, washing, suction filtration and drying, and finally 15.6 g of polyoxyethylene sorbitan monooleate was added, stirred and mixed to prepare a cold filtration point improver.

[0025] Weigh 0.24g of cold filter...

example 2

[0027] This example is the preparation of a diesel oil cold filter point improver

[0028] Put 0.01mol maleic acid mixed alcohol ester, 0.01mol fumaric acid mixed alcohol ester, 0.05mol vinyl acetate and 60g toluene in a container equipped with an electric stirrer, a thermometer, a reflux condenser, and a nitrogen gas introduction tube In the reactor, feed nitrogen for 15-30 minutes, and maintain a weak nitrogen flow during the reaction, heat and stir, and raise the temperature to 40-60°C, add 0.24g composite initiator, 0.05mol mixed alcohol acrylate, and heat up to 70 ~90°C, keep warm for 4-6 hours. The composite initiator is composed of benzoyl peroxide and azobisisobutyronitrile in a mass ratio of 1:0.6. Then through vacuum distillation, washing, suction filtration and drying to obtain a tetrapolymer, finally add 18.45g of polyoxyethylene sorbitan tristearate, stir and mix to prepare a cold filtration point improver.

[0029] Weigh 0.24g of cold filtration point improver,...

example 3

[0031] This example is the preparation of a diesel oil cold filter point improver

[0032] Put 0.01mol maleic acid mixed alcohol ester, 0.01mol fumaric acid mixed alcohol ester, 0.06mol vinyl acetate and 60g toluene in a container equipped with electric stirrer, thermometer, reflux condenser and nitrogen gas introduction tube In the reactor, feed nitrogen for 15-30 minutes, and maintain a weak nitrogen flow during the reaction process, heat and stir, and raise the temperature to 40-60°C, add 0.34g composite initiator, 0.06mol mixed alcohol acrylate, and heat up to 70 ~90°C, keep warm for 4-6 hours. The composite initiator is composed of benzoyl peroxide and azobisisobutyronitrile in a mass ratio of 1:0.6. Then, the tetrapolymer was obtained through vacuum distillation, washing, suction filtration and drying, and finally 11.28 g of polyoxyethylene sorbitan monolaurate was added, stirred and mixed to prepare a cold filtration point improver.

[0033] Weigh 0.24g of cold filtra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com