Reagent for reducing condensation point of diesel, and preparation method and application thereof

A technology of condensation point and diesel oil, which is applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of restricting the use of diesel oil and losing fluidity of diesel oil, and achieve the effect of low cost, fewer types of raw materials, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

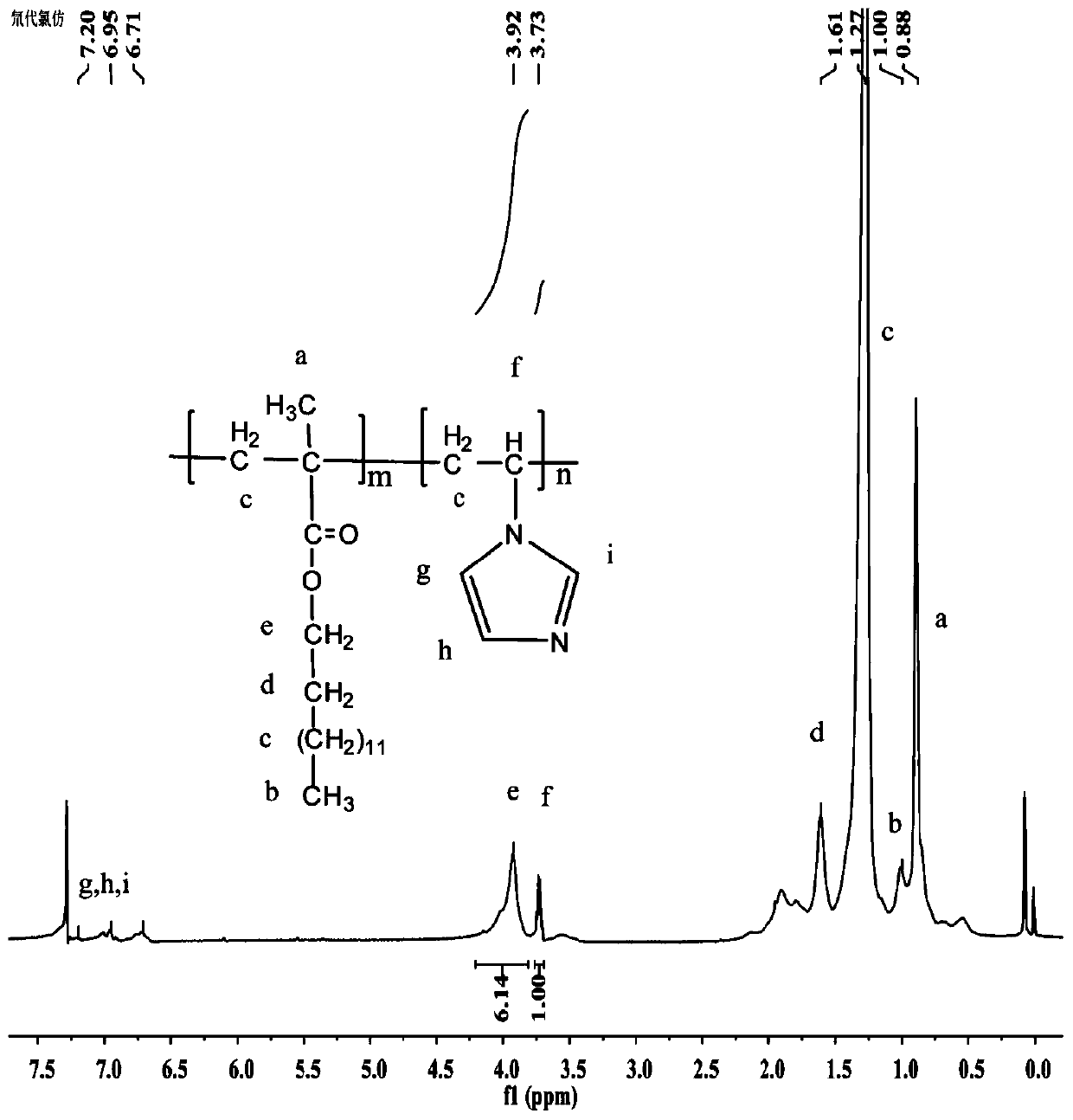

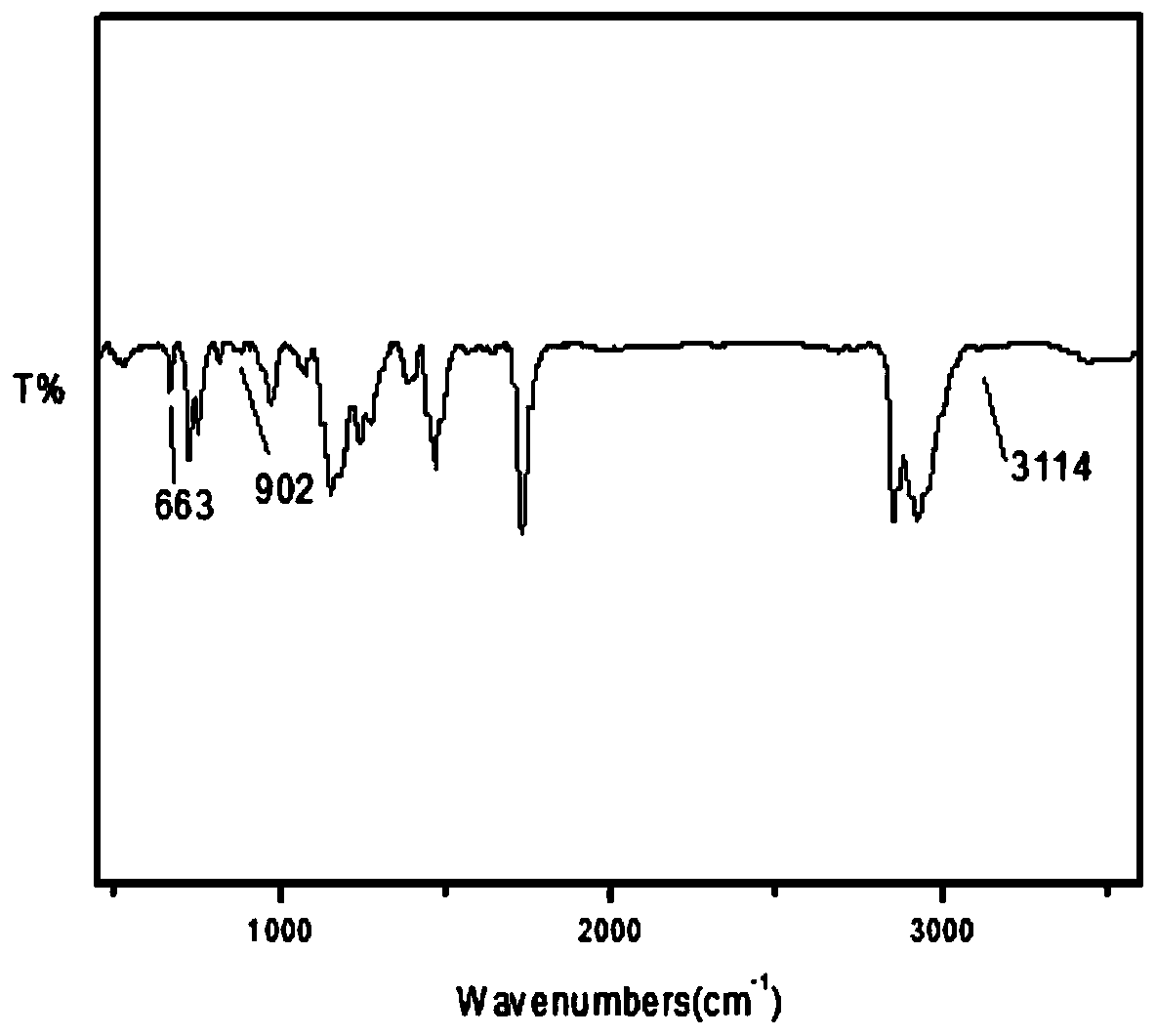

Method used

Image

Examples

Embodiment 1

[0047] A reagent for lowering the condensation point of diesel oil, consisting of myristyl methacrylate-N-vinylpyrrolidone copolymer. Its preparation method is:

[0048](1) there-necked flask is put into the constant temperature magnetic stirrer that thermometer, reflux condenser, water separator are housed, add 20.74g (0.096mol) tetradecyl alcohol, 0.01844g inhibitor hydroquinone, 30ml toluene, Raise the temperature to 60°C to dissolve everything, then quickly add 9.996g (0.116mol) of methacrylic acid and 0.3688g p-toluenesulfonic acid weighed, raise the temperature to 90°C for 1 hour, and continue to raise the temperature to 125°C for 5 hours under reflux. After the reaction, cool to room temperature, pour into a separatory funnel, wash three times with 5% NaOH to weak alkalinity, then wash three times with distilled water to neutrality, stand to separate layers to remove the bottom liquid, and pour the upper layer into a circular The bottom flask was evaporated at 50° C. w...

Embodiment 2

[0051] A reagent for lowering the condensation point of diesel oil, as shown in formula (I), is a copolymer formed by the polymerization of tetradecyl methacrylate and N-vinylpyrrolidone. The molecular Mw of the polymer tested by GPC was 71000 g / mol, the Mn was 31540 g / mol, and the Mw / Mn was 2.251. Its preparation method is similar to that of Example 1, except that 8.7676g (0.03mol) of tetradecyl methacrylate and 1.15g (0.01mol) of N-vinylpyrrolidone are added in step (2).

Embodiment 3

[0053] The diesel pour point depressants prepared in the above examples 1-2 were numbered 1 and 2 respectively, and were added to Songjiang 0# diesel at 0.025%-0.2% of the total mass of diesel, and ultrasonicated at 40°C for 30 minutes. Measure its condensation point according to GB / T510-1991, and measure its cold filter point according to SH / T0248-2006. Take the average of the two results of repeated determinations. Add the 0# diesel oil freezing point and the cold filter point test result of the diesel oil pour point depressant gained in embodiment 1-2 as shown in the table.

[0054]

[0055] As can be seen from the above, the pour point depressant of Example 1-2 has a good pour point depressant effect on 0# diesel oil, and the pour point depressant of the present invention has a significant effect on reducing the condensation point of diesel oil and the cold filter point, and the highest condensation point is reduced by 24°C , the cold filter point decreased by 3°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com