Mesoporous polymer-titanium silicon oxide nano composite material and preparation method thereof

A composite material and polymer technology, applied in the field of mesoporous materials, can solve the problems of uneconomical synthesis of bridged organosilicon sources, expensive surfactants, difficult molecular sieves, etc., and achieves low preparation costs, low equipment requirements, and raw material sources. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] a) Add 1.6g of surfactant F127 and 1ml of dilute hydrochloric acid with a concentration of 0.2mol / L into 10ml of absolute ethanol, and stir at 40°C until the surfactant is completely dissolved;

[0028] b) Add 2.08g tetraethyl orthosilicate (TEOS), and continue stirring at 40°C for 2 hours;

[0029] c) Add 0.0568g of isopropyl titanate and continue stirring at 40°C for 1 hour;

[0030] d) Add 1.0 g of water-soluble phenolic resin with a molecular weight of 300 to 500, and continue stirring at 40° C. for 0.5 hours;

[0031] e) Transfer the reaction solution to an evaporating dish, first volatilize at 30°C for 12 hours, then polymerize at 120°C for 20 hours;

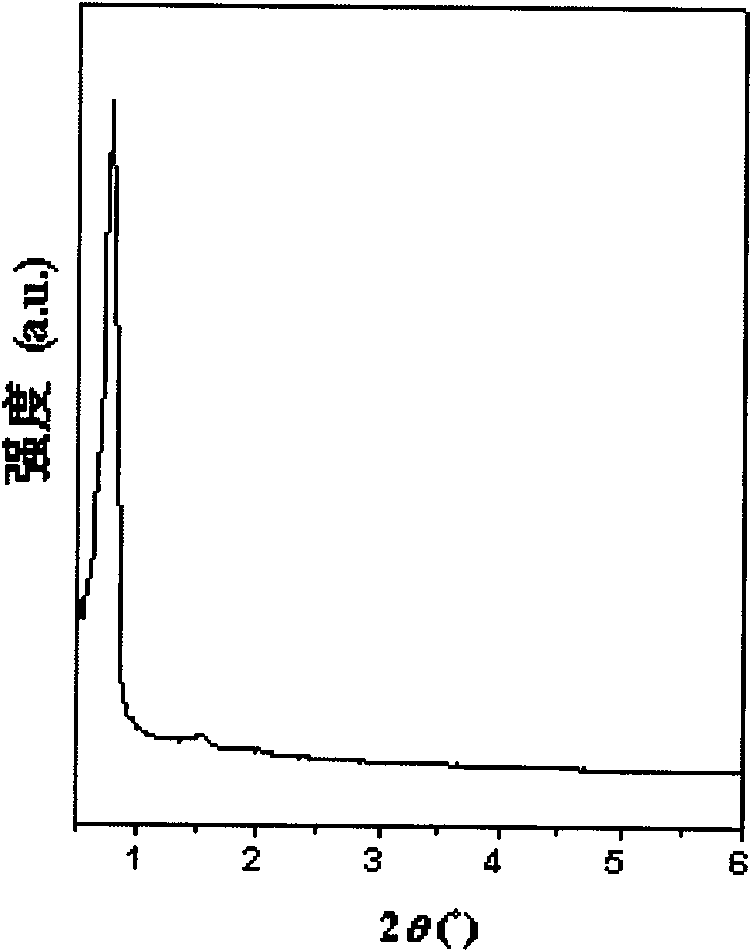

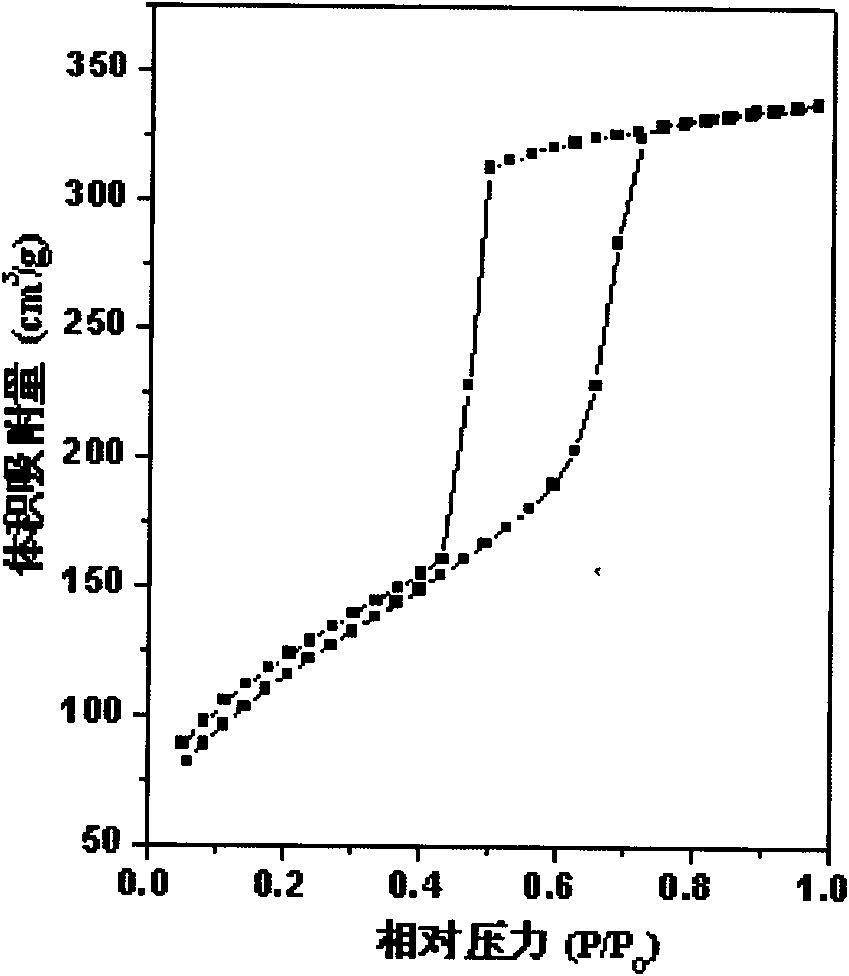

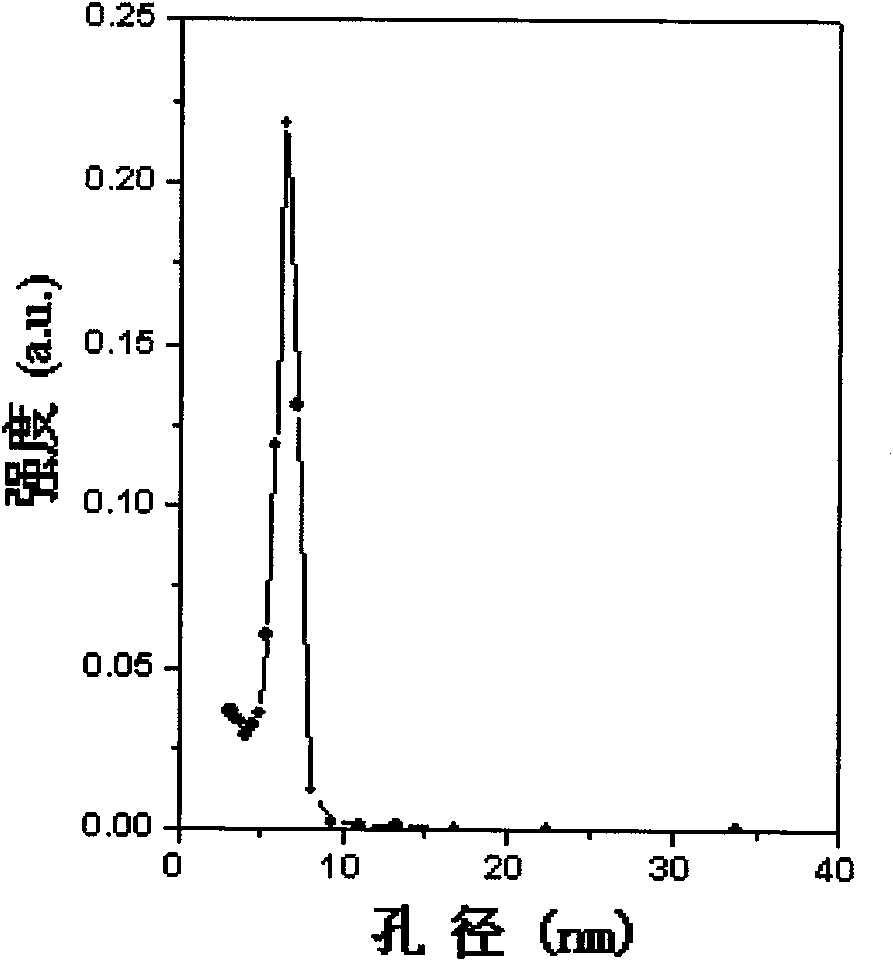

[0032] f) Scrape off the reaction product in the evaporating dish, crush it, and bake it at 350°C for 5 hours under an inert atmosphere with a heating rate of 3°C / min to obtain: the polymer content is 50% [calculated by TG], silicon Mesoporous polymer-titanium oxide silicon nanocomposites with a titanium molar rat...

Embodiment 2

[0041] a) Add 1.6g of surfactant F127 and 1ml of dilute hydrochloric acid with a concentration of 2mol / L into 10ml of absolute ethanol, and stir at 40°C until the surfactant is completely dissolved;

[0042] b) Add 4.98g tetraethyl orthosilicate (TEOS), and continue stirring at 40°C for 2 hours;

[0043] c) Add 0.068g of isopropyl titanate, and continue stirring at 40°C for 1 hour;

[0044] d) Add 1.0 g of water-soluble phenolic resin with a molecular weight of 300 to 500, and continue stirring at 40° C. for 0.5 hours;

[0045] e) Transfer the reaction solution to an evaporating dish, first volatilize at 40°C for 4 hours, then polymerize at 80°C for 48 hours;

[0046] f) Scrape off the reaction product in the evaporating dish, crush it, and bake it at 400°C for 3 hours under an inert atmosphere, and the heating rate is 1°C / min to obtain: the polymer content is 50%, the silicon-titanium molar ratio (Si / Ti) is 100 mesoporous polymer-titanium oxide silicon nanocomposites.

[...

Embodiment 3

[0049] a) Add 1.6g of surfactant F127 and 1ml of dilute hydrochloric acid with a concentration of 1mol / L into 10ml of absolute ethanol, and stir at 30°C until the surfactant is completely dissolved;

[0050] b) Add 4.16g tetraethyl orthosilicate (TEOS), and continue stirring at 40°C for 2 hours;

[0051] c) Add 0.568g of isopropyl titanate and continue stirring at 40°C for 1 hour;

[0052] d) Add 1.0 g of water-soluble phenolic resin with a molecular weight of 300 to 500, and continue stirring at 40° C. for 0.5 hours;

[0053] e) Transfer the reaction solution to an evaporating dish, first volatilize at 20°C for 24 hours, then polymerize at 100°C for 24 hours;

[0054] f) Scrape off the reaction product in the evaporating dish, crush it, and bake it at 250°C for 8 hours under an inert atmosphere, with a heating rate of 5°C / min, to obtain: a polymer content of 50%, a silicon-titanium molar ratio (Si / Ti) is 10 mesoporous polymer-titanium oxide silicon nanocomposites.

[0055...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com