Palladium nanoparticle/carbon nanofiber compound, preparation method and application thereof in electrocatalysis

A carbon nanofiber, palladium nanoparticle technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of high detection potential, interference, etc., to reduce detection overpotential, good dispersion and stability, high The effect of electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

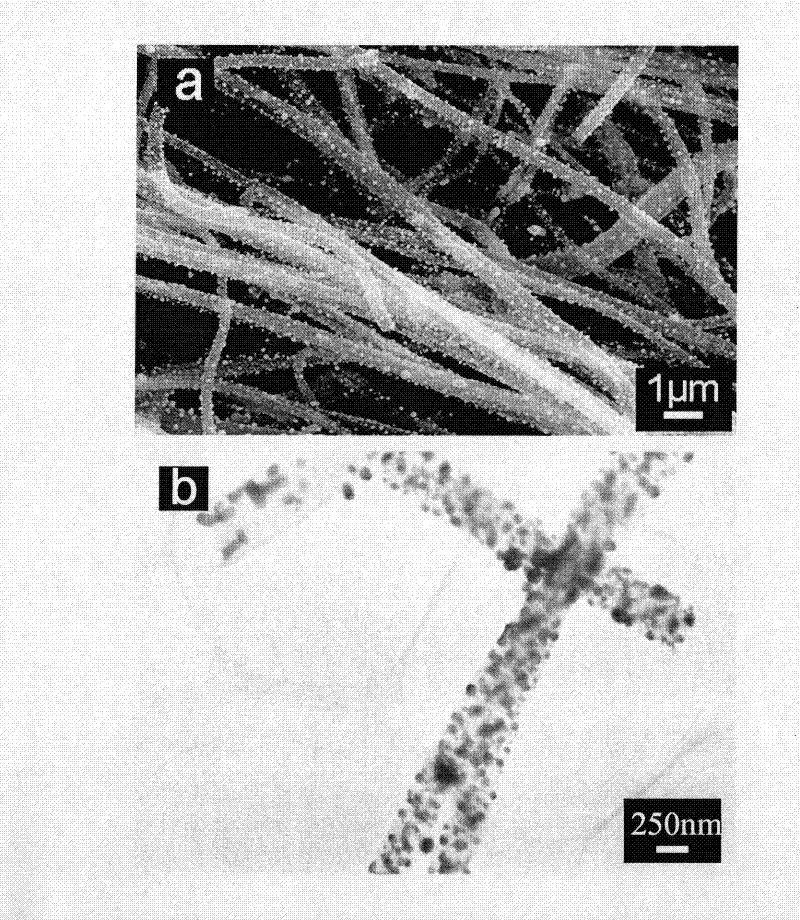

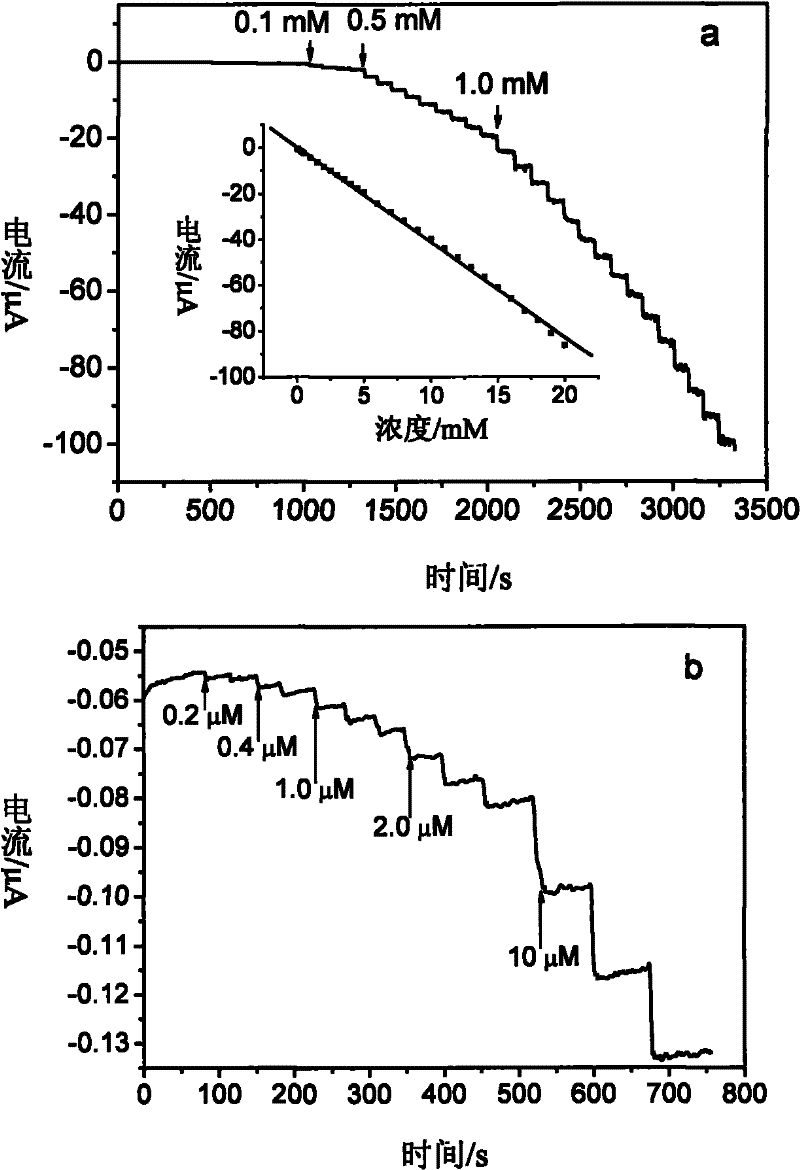

[0060] Embodiment 1, electrospinning prepares Pd / CNF composite material

[0061] 1) Preparation of electrospinning solution: polyacrylonitrile (PAN) and palladium acetate are dissolved in dimethylformamide (DMF) solution to obtain a uniform mixed solution; the content of polyacrylonitrile in the mixed solution is 8wt.%. Palladium acetate content is 4.8wt.%;

[0062] 2) Electrospinning: the uniform mixed solution obtained in step 1) is electrospun in an electric field with an electric field strength of 100kV / m to prepare polyacrylonitrile composite fibers containing palladium acetate, and the distance between the spinneret and the collecting plate is 30cm. The applied voltage is 30kV;

[0063] 3) annealing the polyacrylonitrile composite fiber containing palladium acetate obtained in step 2) at 230° C. for 3 hours to partially oxidize the PAN nanofiber;

[0064] 4) Raise the temperature to 300°C at a rate of 5°C / min, and feed H at this temperature 2 and Ar mixed gas 2h, wher...

Embodiment 2

[0067] Embodiment 2, electrospinning prepares Pd / CNF composite material

[0068] 1) Preparation of electrospinning solution: polyacrylonitrile (PAN) and palladium acetate are dissolved in dimethylformamide (DMF) solution to obtain a uniform mixed solution; the content of polyacrylonitrile in the mixed solution is 15wt.%. Palladium acetate content is 6wt.%;

[0069] 2) Electrospinning: the uniform mixed solution obtained in step 1) is electrospun in an electric field with an electric field strength of 100kV / m to prepare polyacrylonitrile composite fibers containing palladium acetate, and the distance between the spinneret and the collecting plate is 30cm. The applied voltage is 30kV;

[0070] 3) annealing the polyacrylonitrile composite fiber containing palladium acetate obtained in step 2) at 230° C. for 3 hours to partially oxidize the PAN nanofiber;

[0071] 4) Raise the temperature to 300°C at a rate of 5°C / min, and feed H at this temperature 2 and Ar mixed gas 2h, where...

Embodiment 3

[0074] Embodiment 3, electrospinning prepares Pd / CNF composite material

[0075] 1) Preparation of electrospinning solution: polyacrylonitrile (PAN) and palladium acetate are dissolved in dimethylformamide (DMF) solution to obtain a uniform mixed solution; the content of polyacrylonitrile in the mixed solution is 5wt.%. Palladium acetate content is 2wt.%;

[0076] 2) Electrospinning: the uniform mixed solution obtained in step 1) is electrospun in an electric field with an electric field strength of 100kV / m to prepare polyacrylonitrile composite fibers containing palladium acetate, and the distance between the spinneret and the collecting plate is 30cm. The applied voltage is 30kV;

[0077] 3) annealing the polyacrylonitrile composite fiber containing palladium acetate obtained in step 2) at 230° C. for 3 hours to partially oxidize the PAN nanofiber;

[0078] 4) Raise the temperature to 300°C at a rate of 5°C / min, and feed H at this temperature 2 and Ar mixed gas 2h, where,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com