Preparation method of photocatalysis materials of biomorphic fine hiberarchy

A photocatalytic material, hierarchical structure technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as the lack of advantages in catalytic properties, achieve outstanding decomposition efficiency, and facilitate photocatalytic performance. , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

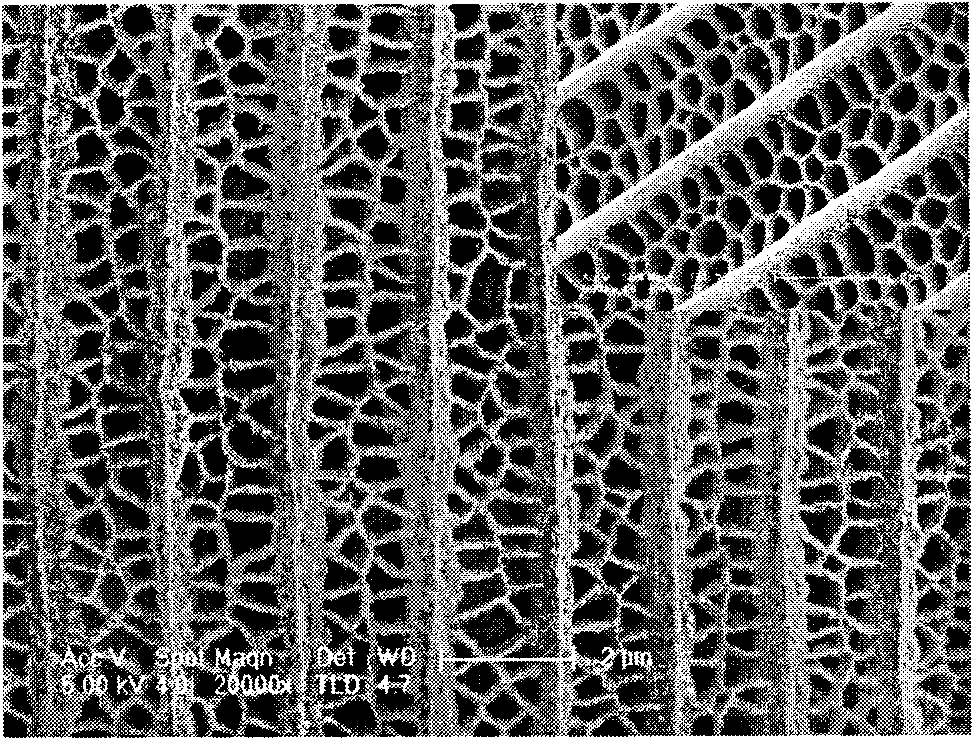

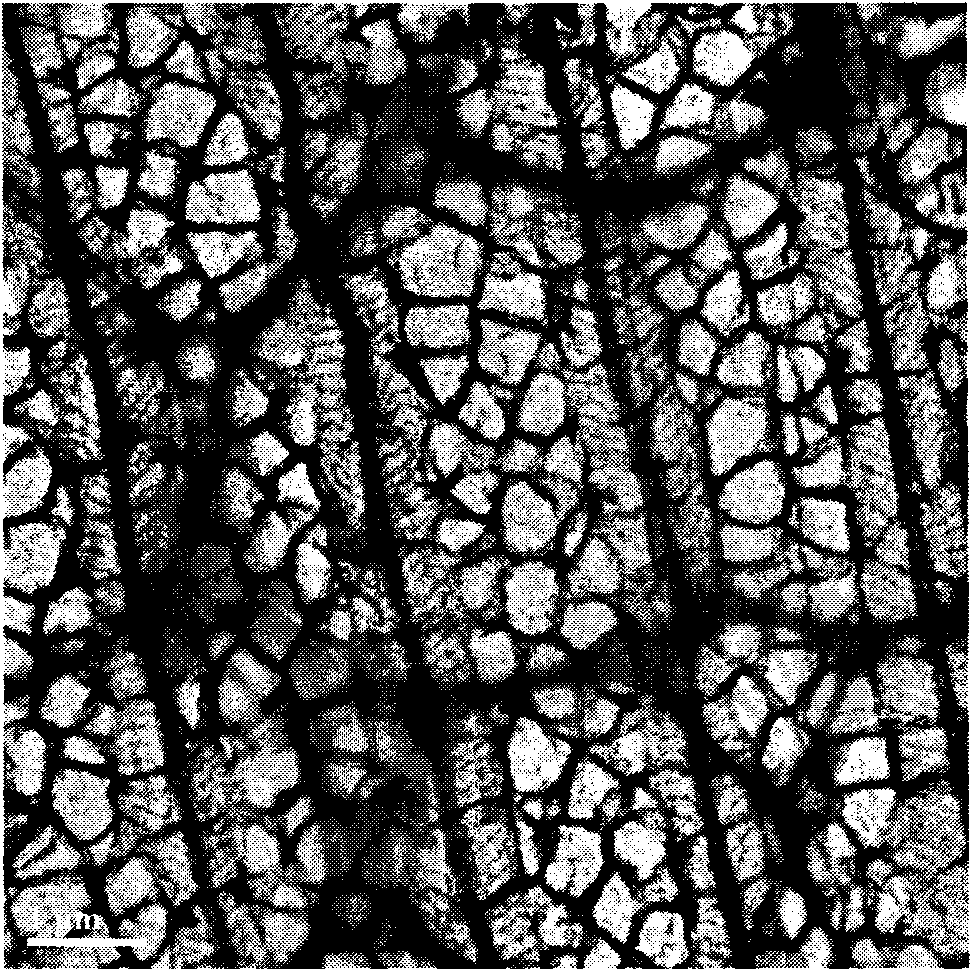

[0023] Select the black part of the biological material Papilio paris butterfly wing as a biological template, soak it in 5% hydrochloric acid for 1 hour, take it out and wash it fully with distilled water, then immerse it in 8% sodium hydroxide solution at 50 ℃ water bath for 1 hour, take it out and rinse it with distilled water, and then air-dry it in an oven at 50 ℃ to obtain the pretreated butterfly wings.

[0024] Add 1mL of tetrabutyl titanate dropwise into a mixed solution of cyclohexane (20mL), oleic acid (15mL) and triethylamine (5mL), stir well to obtain an impregnation solution, transfer it into a reaction kettle, and put the The treated butterfly wings are immersed in the dipping solution, and kept at 150°C for 24 hours. After natural cooling, the butterfly wings are taken out of the reaction kettle, cleaned with organic solvents, clamped with glass sheets, and placed in an oven at 60°C. Air dry.

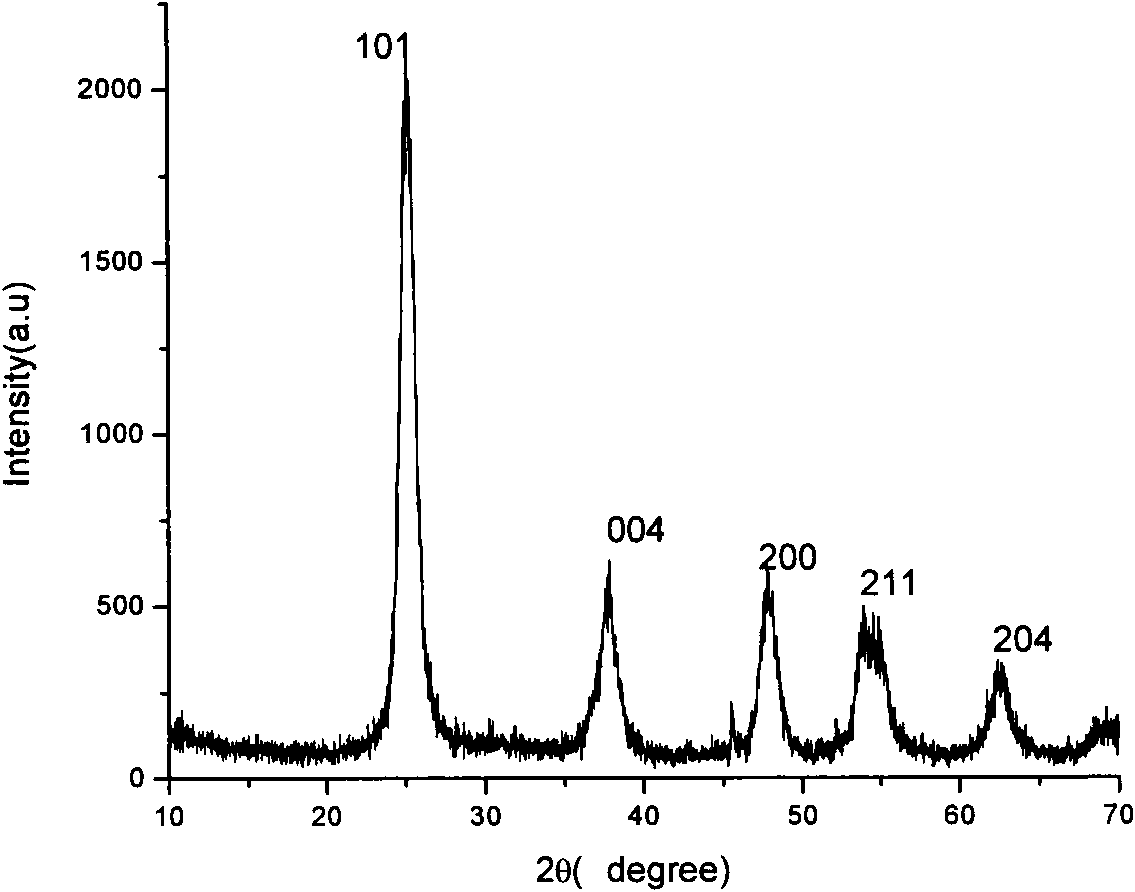

[0025] Put the dried butterfly wings into a high-temperature furna...

Embodiment 2

[0031] Select the black part of the biological material Papilio paris butterfly wing as a biological template, soak it in 5% hydrochloric acid for 1 hour, take it out and wash it fully with distilled water, then immerse it in 8% sodium hydroxide solution at 50 ℃ water bath for 1 hour, take it out and rinse it with distilled water, and then air-dry it in an oven at 50 ℃ to obtain the pretreated butterfly wings.

[0032]Add 1mL of tetrabutyl titanate dropwise into a mixed solution of cyclohexane (20mL), oleic acid (7mL) and triethylamine (5mL), stir well to obtain an impregnation solution, transfer it into a reaction kettle, and put the The treated butterfly wings are immersed in the dipping solution, and kept at 150°C for 48 hours. After natural cooling, the butterfly wings are taken out of the reaction kettle, cleaned with organic solvents, clamped with glass sheets, and placed in an oven at 60°C. Air dry.

[0033] Put the dried butterfly wings into a high-temperature furnace...

Embodiment 3

[0035] Select the black part of the Paris Emerald Papillon butterfly wing as a biological template, soak it in 5% dilute hydrochloric acid for 1 hour, take it out and wash it fully with distilled water, and then immerse it in a dilute sodium hydroxide solution with a mass concentration of 8%. Soak it in a water bath at 50°C for 1 hour, take it out and rinse it with distilled water, and then dry it in an oven at 50°C to obtain the pretreated butterfly wings.

[0036] Add 1mL of tetrabutyl titanate dropwise into a mixed solution of cyclohexane (20mL), oleic acid (20mL) and triethylamine (5mL), stir well to obtain an impregnation solution, transfer it into a reaction kettle, and put the The treated butterfly wings are immersed in the dipping solution, and kept at 150°C for 24 hours. After natural cooling, the butterfly wings are taken out of the reaction kettle, cleaned with organic solvents, clamped with glass sheets, and placed in an oven at 60°C. Air dry.

[0037] Put the dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com