Preparation method and application of core-shell type Fe3O4/C magnetic nano solid extracting agent

A solid-phase extraction agent and magnetic nanotechnology, which is applied in the direction of inorganic material magnetism, other chemical processes, chemical instruments and methods, etc., can solve the problems of strong binding ability and difficult elution of target objects, achieve strong extraction ability and fast processing process , the effect of less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the preparation method of magnetic nanomaterial extraction agent of the present invention

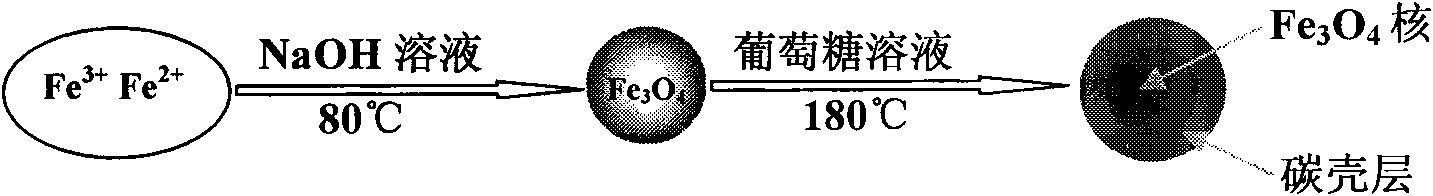

[0024] The core-shell Fe provided by the present invention 3 o 4 The synthetic schematic diagram of / C magnetic nanomaterial extractant is as figure 1 As shown, its specific preparation method can be divided into the following two steps:

[0025] First, prepare nano-iron oxide. First, 5.2g FeCl 3 ·6H 2 O and 2.0 g FeCl 2 4H 2 O and 0.85mL of concentrated hydrochloric acid were dissolved in 25mL of N 2 In the deoxygenated aqueous solution; under vigorous mechanical stirring, add the above solution dropwise to 250mL 1.5mol / L NaOH aqueous solution, and continue to stir and react for 0.5 hours after the dropwise addition; Nanoparticles are separated.

[0026] Second, the preparation of core-shell Fe 3 o 4 / C magnetic nanomaterials. Take a quarter of the prepared Fe 3 o 4 Magnetic particles, washed three times with deionized water, then washed twice with et...

Embodiment 2

[0027] Embodiment 2: Structural characterization of magnetic nanomaterial extractant of the present invention

[0028] This embodiment is to carry out structural characterization to the magnetic nanomaterial extraction agent prepared in embodiment 1, specifically as follows:

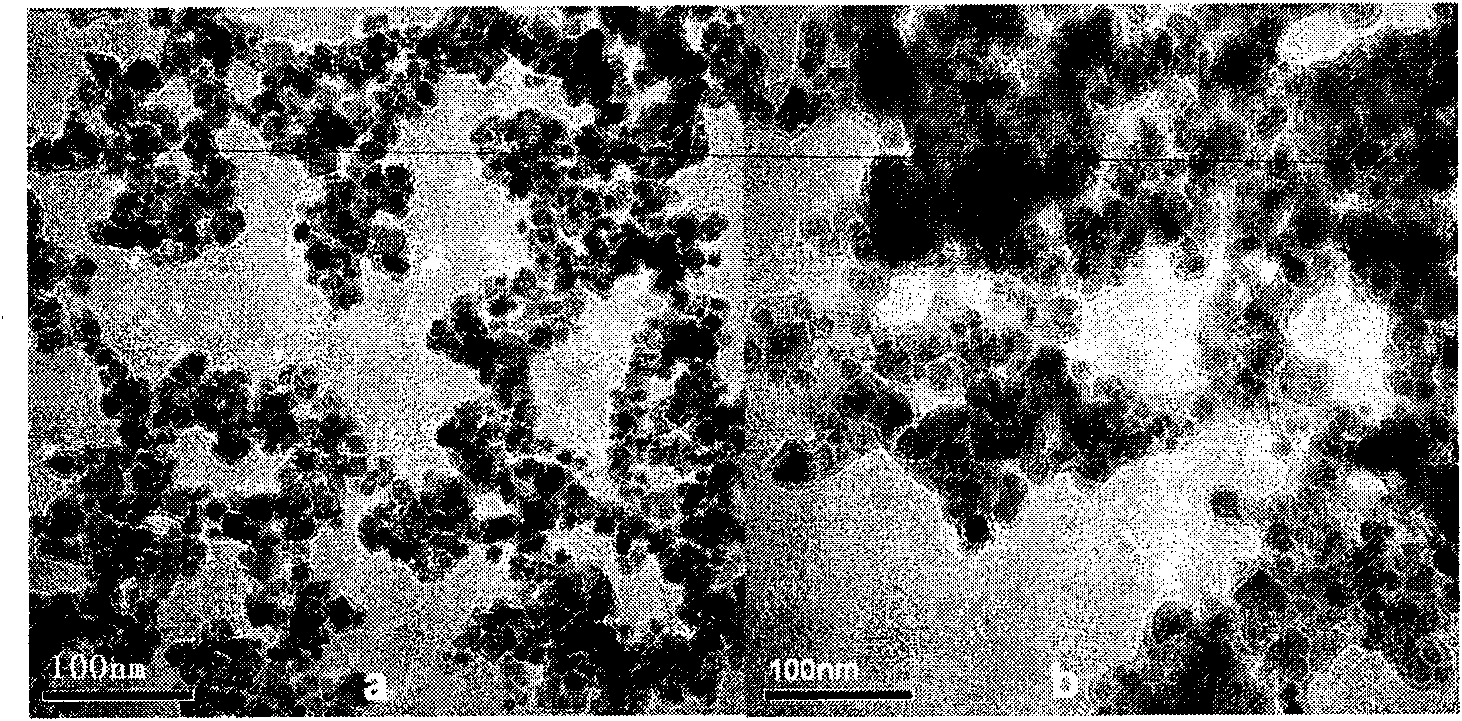

[0029] 1. Particle size and morphology characterization

[0030] The prepared core-shell Fe was observed by transmission electron microscopy (TEM) 3 o 4 / C magnetic nanomaterial, its TEM picture is as figure 2 shown. From figure 2 It can be seen that the prepared Fe 3 o 4 / C nanoparticles are basically spherical, and the darker part of the inner layer is Fe 3 o 4The magnetic core has a particle size of about 10nm, and the lighter part of the outer layer is the coated carbon material. The coating layer is 2-5nm, and the entire nanoparticle presents an obvious core-shell structure.

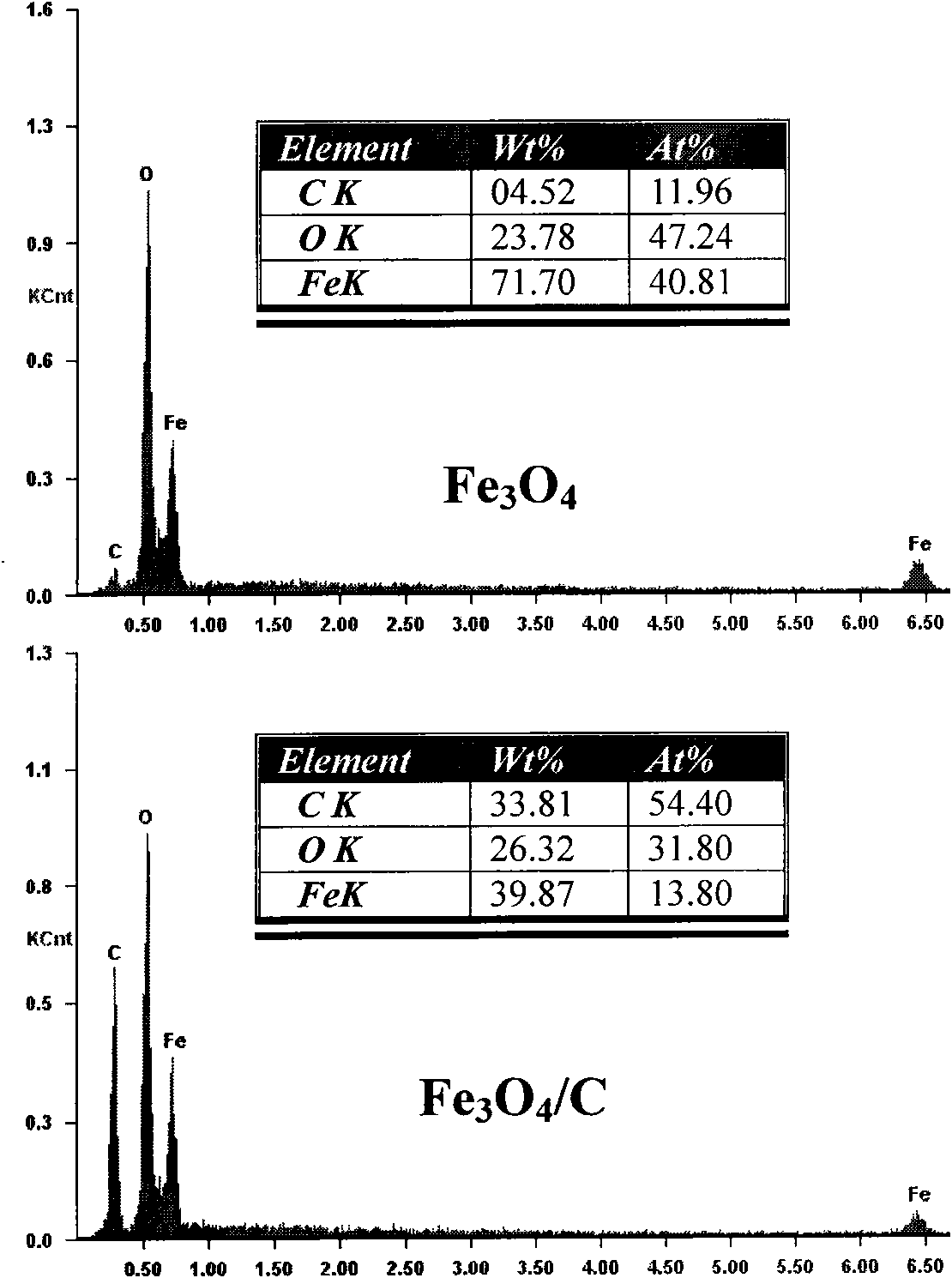

[0031] 2. Elemental analysis

[0032] Determination of prepared Fe by X-ray energy spectrometer 3 o 4 and Fe ...

Embodiment 3

[0037] Embodiment 3: Adsorption performance test of magnetic nanomaterial extractant of the present invention

[0038] This embodiment selects alkylphenol pollutants bisphenol A (BPA), nonylphenol (4-OP) and octylphenol (4-NP), phthalate pollutants n-propyl phthalate (DPP), n-butyl phthalate (DBP), cyclohexyl phthalate (DCP) and n-octyl phthalate (DOP), polycyclic aromatic hydrocarbon pollutants phenanthrene (PhA), fluoranthene (FluA), pyrene (Pyr), benzene A[a]anthracene (BaA), benzo[b]fluoranthene (BbF), benzo[a]pyrene (BaP), benzo[g,h,i]perylene (BghiP), etc. are common pollutants Representative, the adsorption performance of the magnetic nanomaterial extractant prepared in Example 1 was tested.

[0039] The operation steps of the test are as follows: Figure 6 As shown, the specific experimental process is as follows: add an appropriate amount of standard solutions of various pollutants to the water sample, stir evenly, add the prepared magnetic nanomaterial solid phase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Saturation magnetic strength | aaaaa | aaaaa |

| Saturation magnetic strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com