Method for removing impurity iron from hydrochloric acid raw phosphoric acid by solvent extraction process

A technology of crude phosphoric acid and hydrochloric acid method, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high impurity content, increased viscosity of phosphoric acid, high cost, etc., and achieve low operating cost, high atom utilization, and extraction powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

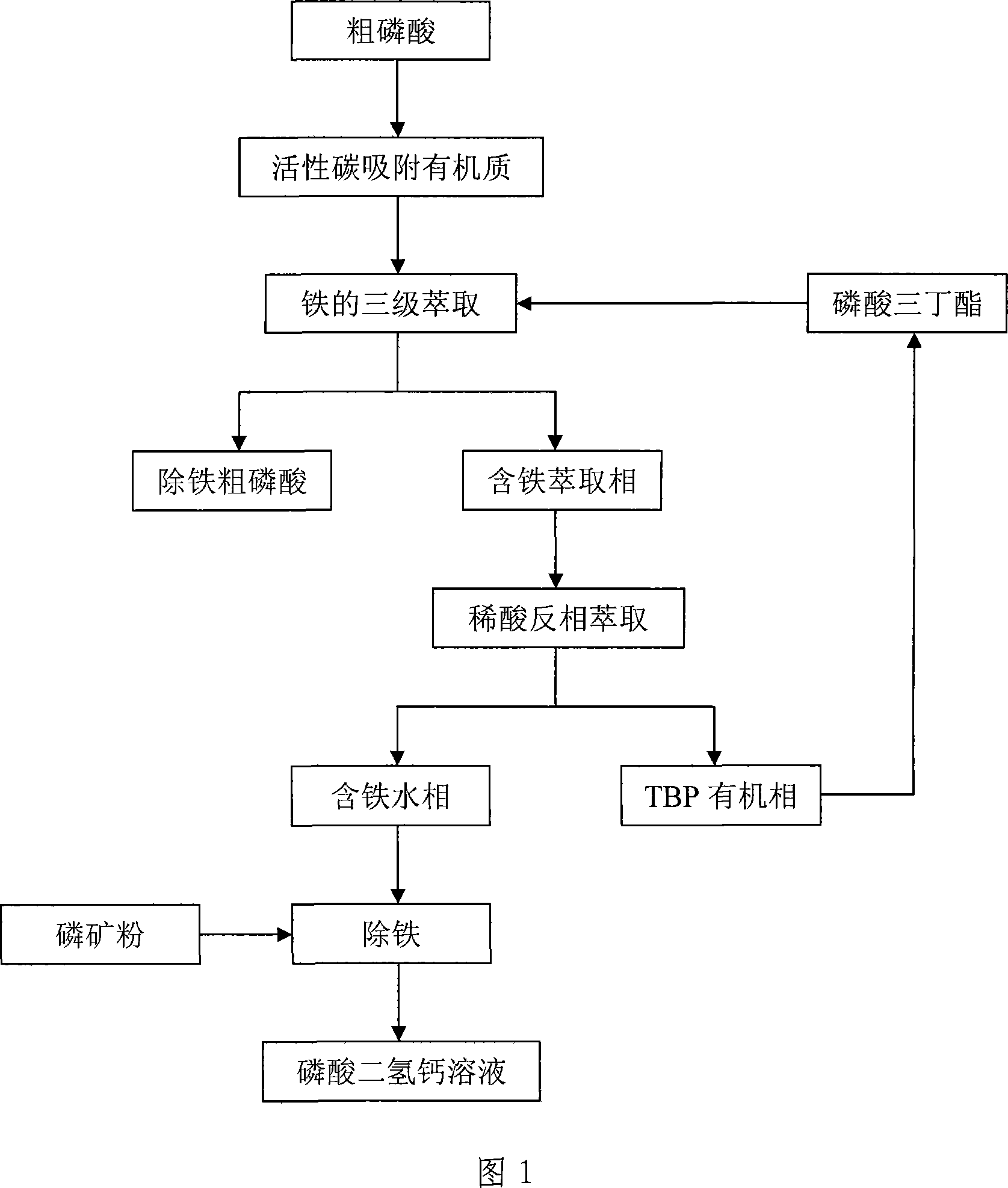

Image

Examples

Embodiment 1

[0015] 1), the density d = 1.3157, P 2 o 5 Content is 7.02% hydrochloric acid process crude phosphoric acid is added active carbon according to mass ratio is 100: 1, the organic impurity in crude phosphoric acid is adsorbed and removed; Add tributyl phosphate, preheat in a water bath at 30°C for 10 minutes, mix the two-phase solution, shake for 10 minutes, let stand to separate the layers, separate the iron-containing extract phase, and the number of continuous extraction stages is 3 to remove crude phosphoric acid by hydrochloric acid method Medium impurity iron, get iron phosphoric acid.

[0016] Treat the separated iron-containing extraction phase: 1), add 0.0001 mol / L hydrochloric acid to the iron-containing extraction phase according to the organic phase / water phase volume ratio 1:1, shake at 35°C for 10 minutes, and let stand to separate layers , separate the iron-containing aqueous phase, and the continuous extraction stage is 2; 2), add phosphate rock powder in the i...

Embodiment 2

[0021] 1), the density d = 1.3157, P 2 o 5 7.02% hydrochloric acid process crude phosphoric acid is added to activated carbon at a mass ratio of 100:1 to adsorb and remove organic impurities in crude phosphoric acid; 2), in crude phosphoric acid, the organic phase / water phase volume ratio is 1:6 Add tributyl phosphate, preheat in a water bath at 40°C for 10 minutes, mix the two-phase solution, shake for 10 minutes, let stand to separate the layers, separate the iron-containing extract phase, and the number of continuous extraction stages is 3 to remove crude phosphoric acid by hydrochloric acid method Medium impurity iron, get iron phosphoric acid.

[0022] Treat the separated iron-containing extraction phase: 1), add 0.0001mol / L hydrochloric acid to the iron-containing extraction phase according to the organic phase / water phase volume ratio of 1:1, shake at 35°C for 10 minutes, and let stand to separate layers , separate the iron-containing aqueous phase, and the continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com