Method for treating high-salt water by air stripping type membrane distillation

A treatment method, high brine technology, applied in the field of water desalination treatment, can solve the problems of less research and reports on membrane fouling, lower membrane water flux, lower membrane efficiency, etc., to control membrane fouling, increase membrane permeation flux, The effect of lowering the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

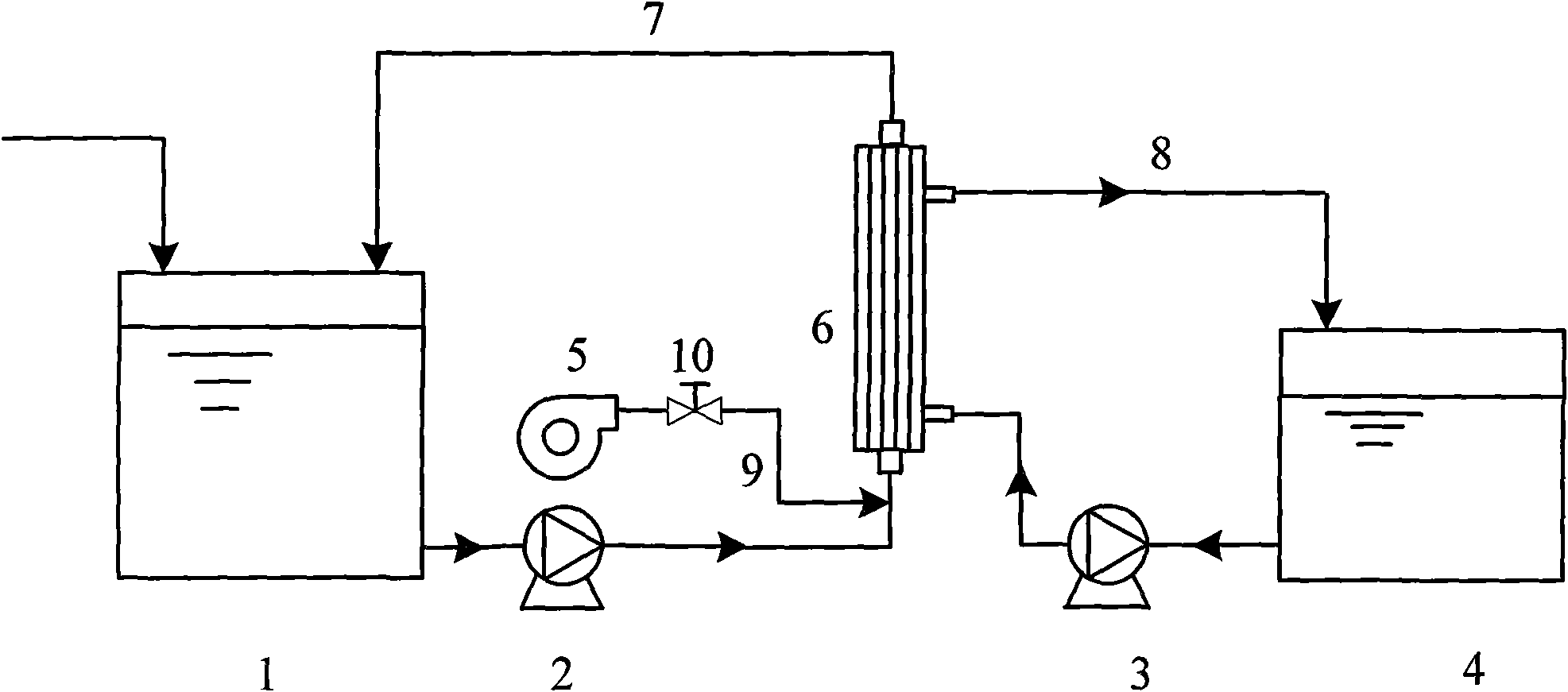

Image

Examples

Embodiment 1

[0017] Example 1: Pilot test of high salt water treatment project, the salt concentration in the feed liquid is 6%, and the treatment capacity is 5m 3 / d, the liquid flow velocity on both sides of the cold and hot sides is 0.4~0.5m / s and 0.08~0.15m / s respectively, the feed temperature is 55℃, 65℃, 75℃ respectively, the cooling water temperature is 35℃, and the cooling water is reverse Permeate deionized water with a conductivity of 20μs / cm. The test results show that the membrane flux reaches 10kg / m under all operating conditions 2 For more than h, the membrane flux is increased by 15% compared with when the air stripping technology is not used, and the stable product water conductivity is maintained between 25 and 30 μs / cm, and the treatment effect is good.

Embodiment 2

[0018] Example 2: Pilot test of reverse osmosis concentrated water treatment project, the conductivity of concentrated water is 8000μs / cm, and the treatment capacity is 5m 3 / d, the liquid flow velocity on both sides of the cold and hot sides is 0.4~0.5m / s and 0.08~0.15m / s respectively, the feed temperature is 55℃, 65℃, 75℃ respectively, the cooling water temperature is 35℃, and the cooling water is reverse Permeate deionized water with a conductivity of 20μs / cm. The test results show that under all operating conditions, the membrane flux reaches 11kg / m 2 For more than h, the membrane flux is increased by 10% compared with when the air stripping technology is not used, and the stable product water conductivity is maintained between 25 and 30 μs / cm, and the treatment effect is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com