In-site composite method for Ag/SBA-15 catalyzer

A technology of in-situ synthesis and synthesis method, which is applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of high CO complete oxidation temperature, low Ag loading, etc., and achieves easy industrial application and improved The effect of silver content and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

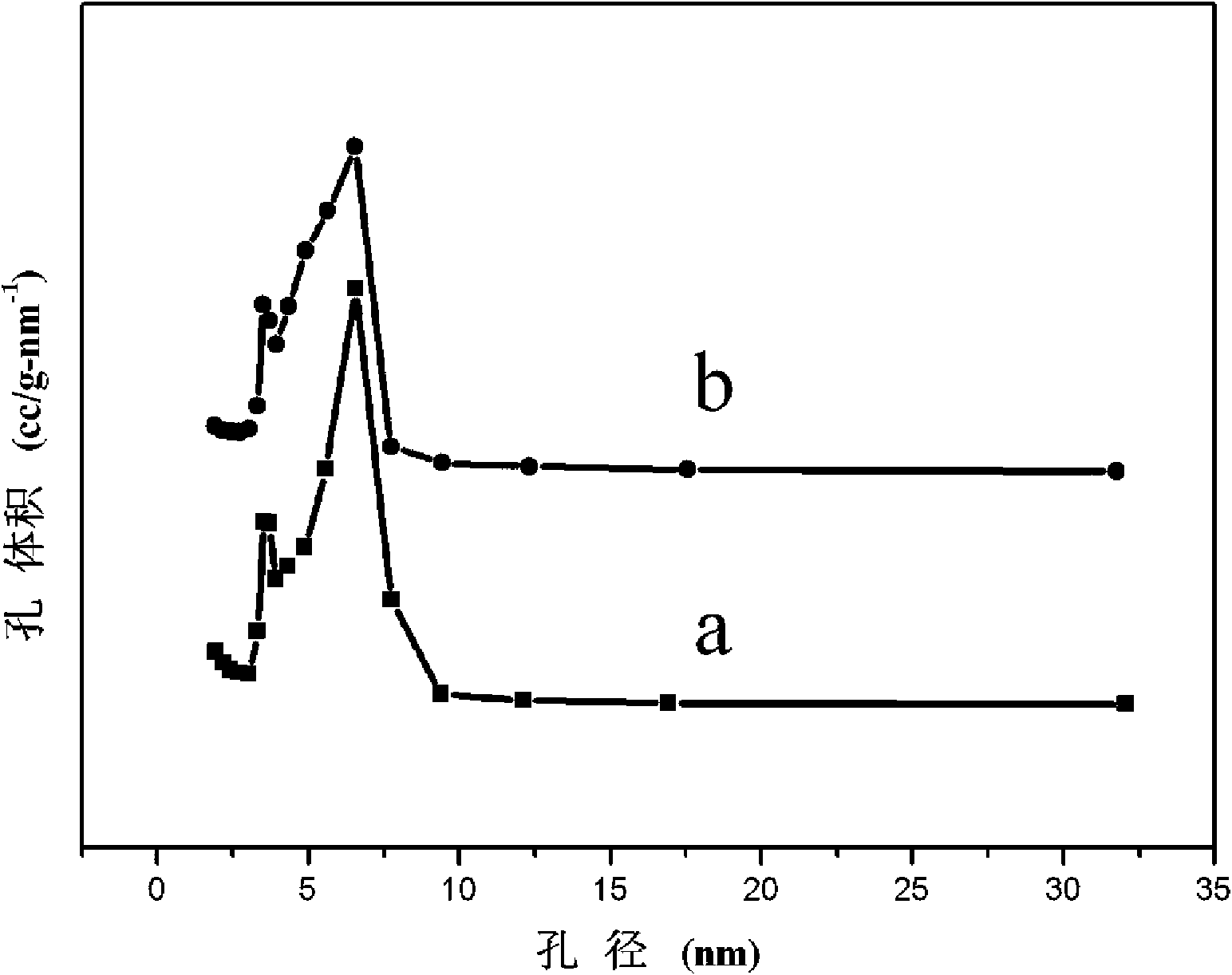

Image

Examples

Embodiment 1

[0020] Add 4g of P123 into the pre-prepared 0.5mol / L nitric acid solution, stir in a water bath at 40°C, and dissolve P123 completely until a transparent solution is formed. Add 0.378g of silver nitrate to the solution, stir for 2 hours, then add 9ml of tetraethyl orthosilicate to the solution, and after stirring for 20 hours, transfer the obtained microemulsion to an autoclave, put it in an oven at 100°C for 48 hours to stand for crystallization, After cooling to room temperature, adjust the pH of the solution to 5 with ammonia water, then transfer the mixed solution to an autoclave, put it in an oven at 100°C for crystallization for 48 hours, filter it after cooling to room temperature, wash it, and place it in a vacuum drying oven at 70°C After drying for 12 hours, the Ag / SBA-15 catalyst can be obtained by calcining at 540°C for 10 hours in a muffle furnace under an air atmosphere.

Embodiment 2

[0022] According to the preparation method of the present invention in Example 1, the two steps of alkali adjustment of pH and recrystallization were omitted to prepare the Ag / SBA-15 catalyst.

Embodiment 3

[0024] According to the preparation method of the present invention in Example 1, 4gP123 was added to the pre-prepared 1mol / L nitric acid solution, stirred at 35°C in a water bath, and the hydrothermal reaction was left to crystallize at 80°C for 24h to obtain Ag / SBA- 15 catalysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com