Method and device for continuously measuring dynamic fluid consumption

A technology for measuring dynamics and consumption. It is applied in measurement devices, mass flow measurement devices, measurement capacity, etc., and can solve the problem that the measurement system is not an open system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

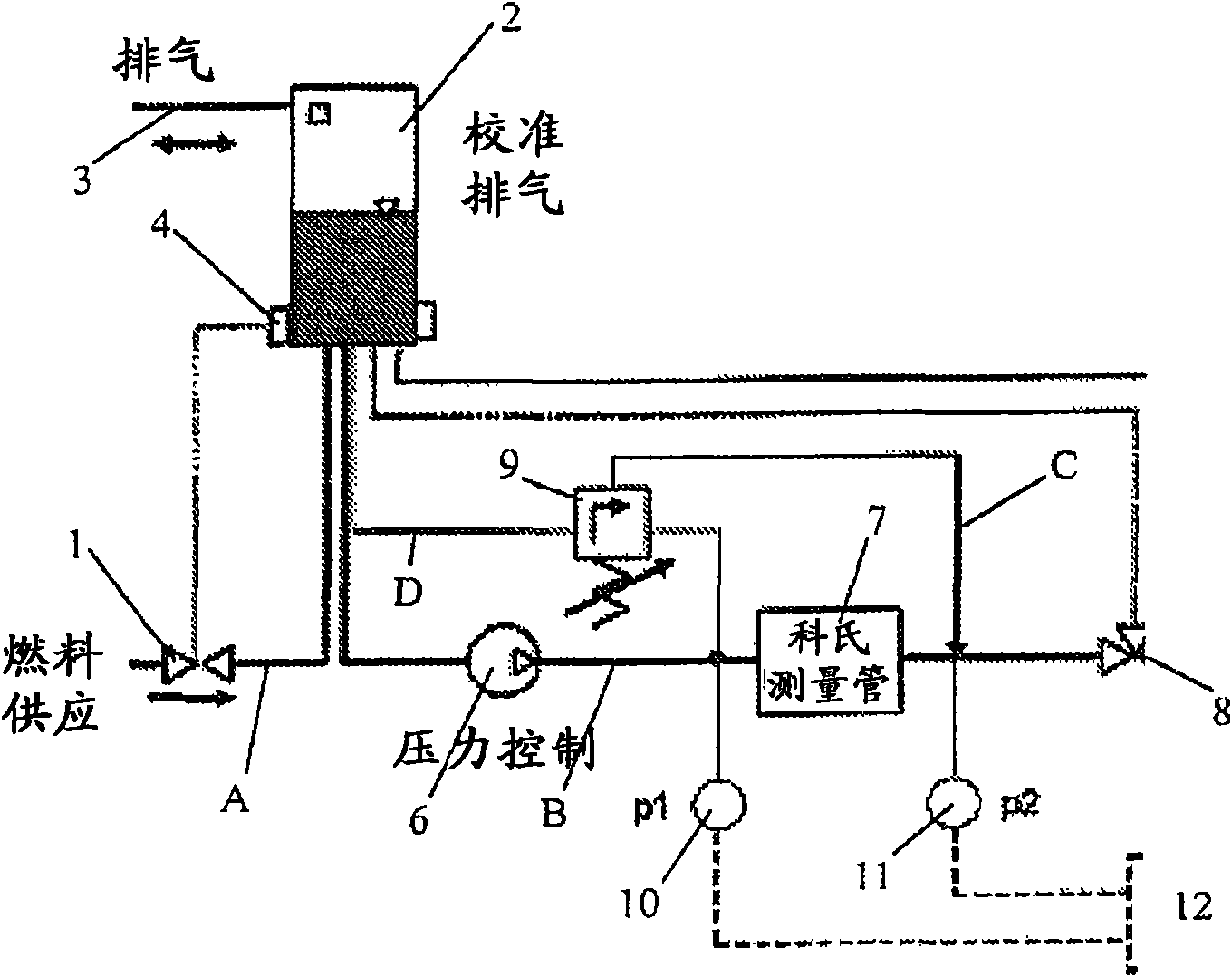

[0019] Via a line A and a filling valve 1 (preferably actuatable electromagnetically), a tank 2 as a storage container is supplied with liquid (ie fuel). The oil tank 2 also has a vent valve 3 and a liquid level sensor 4 connected to the filling valve 1 .

[0020] Fuel is fed from tank 2 via line B to a continuously operating flow sensor 7 , preferably a Coriolis sensor, by means of a preferably controllable fuel pump 6 . The fuel then preferably passes via the non-return valve 8 to an output location to which an engine as load (not shown) is connected and at which fuel with a predetermined specific pressure should be supplied.

[0021] A line C is tapped between the flow sensor 7 and the non-return valve 8 , which leads to a control input of, for example, a mechanical hydraulic pressure regulator 9 . The flow through line D, which is tapped off from line B between the fuel pump 6 and the flow sensor 7, is now regulated by the pressure regulator 9 depending on the pressure in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com