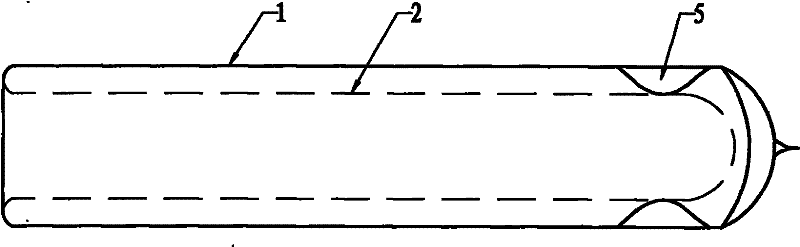

Vacuum collector tube and manufacturing method thereof

A technology of vacuum heat collecting tubes and manufacturing methods, applied in solar heat collectors, solar heat collectors using working fluids, heating devices, etc., can solve the problems of loss of heat absorption, film removal, shedding, etc., and achieve light-to-heat conversion performance High, guaranteed heat collection effect, efficient heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

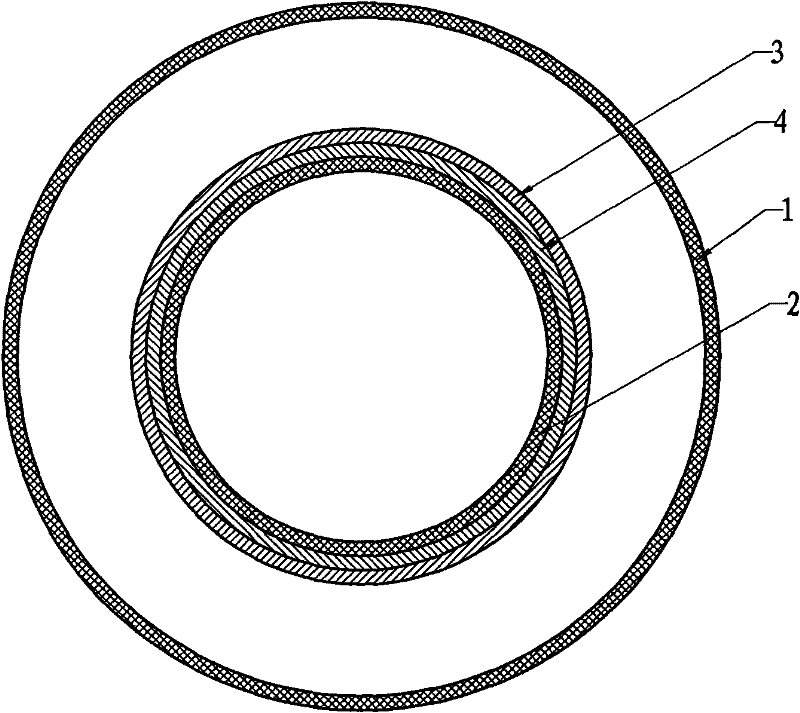

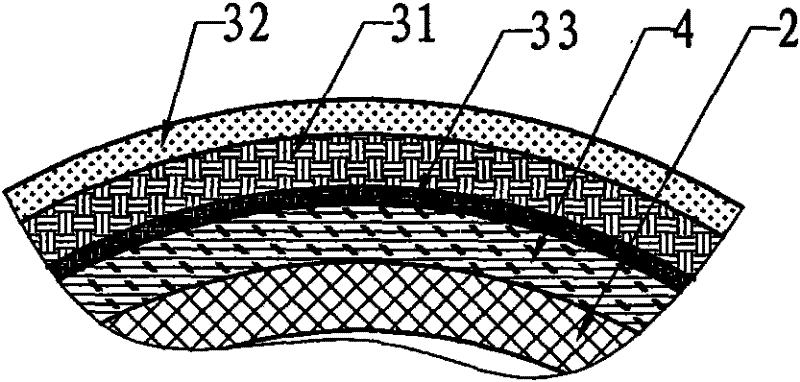

[0024] The manufacturing method of the vacuum heat collecting tube: after the glass inner tube is manufactured, when preparing a film layer on the outer surface of the glass inner tube, firstly choose aluminum foil or copper foil as the metal base layer, and the thickness of the metal base layer is 0.01-0.3 mm. An aluminum nitride compound absorption layer is formed on one side of the metal base layer by a sputtering process or a chrome-plated absorption layer is formed by an electroplating process, and a reflective layer is formed by polishing the surface of the metal base layer on the other side of the metal base layer by a polishing process.

[0025] The film layer is cut, and then the prepared film layer is covered and bonded on the outer surface of the glass inner tube with a heat-conducting transparent organic adhesive, so that there is no gap between the film layer and the glass inner tube. The organic adhesive can be selected to use an organic adhesive that can withstan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com