Wholly aromatic liquid crystal polymer and preparation method thereof

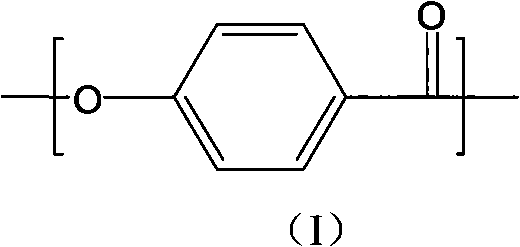

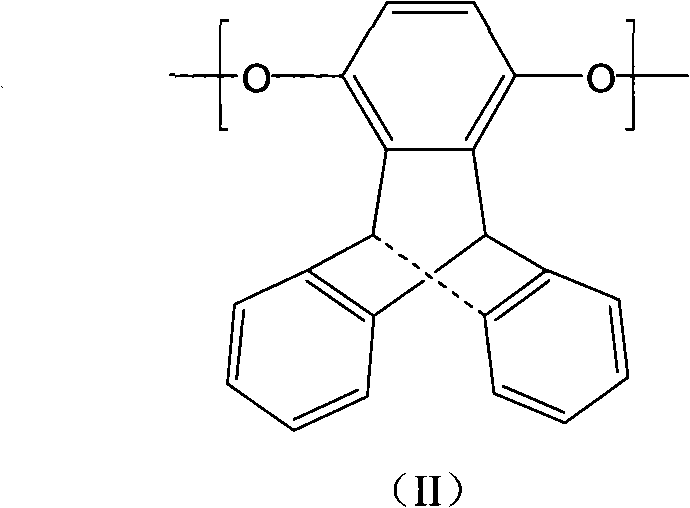

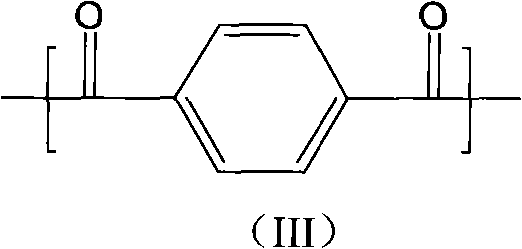

A liquid crystal polymer, wholly aromatic technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of high liquid crystal polymer prices, insufficient supply of raw materials, uncertain commercialization prospects, etc., and achieve excellent melt processing. Effects of performance, reduction in intermolecular forces, and increase in molecular width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0018] with N 2 In the 500ml three-neck flask of gas inlet, barbed splitter, condenser, distillation head, receiver and agitator, add reactant p-hydroxybenzoic acid, triptycene hydroquinone, terephthalic acid, isophthalic acid and Acetic anhydride (the molar amount of acetic anhydride is twice the total of the four monomeric hydroxyl groups) and 0.1% by weight catalyst potassium acetate. Reflux at 145°C for 3 hours, then raise the temperature to 340°C at 25°C / h, and keep the reaction for 30 minutes. Slowly evacuate to 0.25mmHg, and finally keep the temperature and pressure for 30 minutes. After cooling, the prepolymer was taken out, pulverized by a universal pulverizer, and vacuum-dried at 120° C. for 2 hours. N 2 Flow down (50ml / min), solid phase polycondensation reaction at 280°C for 15 hours. The composition and properties of the copolymers are listed in Table 1.

[0019] Table 1 Copolymer composition and properties

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com