Modified polyvinyl alcohol

A polyvinyl alcohol, modification technology, applied in the field of polyvinyl alcohol, can solve the problems of poor melt processing performance of modified polyvinyl alcohol, low difference between melting temperature and decomposition temperature, difficult direct melt processing, etc., to achieve melt processing The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

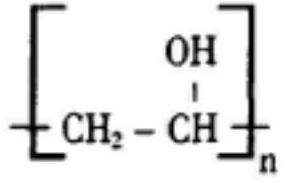

[0088] The synthesis of modified PVA is specifically:

[0089] Use a polymerization tank (continuous polymerization device) equipped with a reflux condenser, raw material feeding system, reaction liquid discharging system, thermometer, nitrogen adding system and stirring blade;

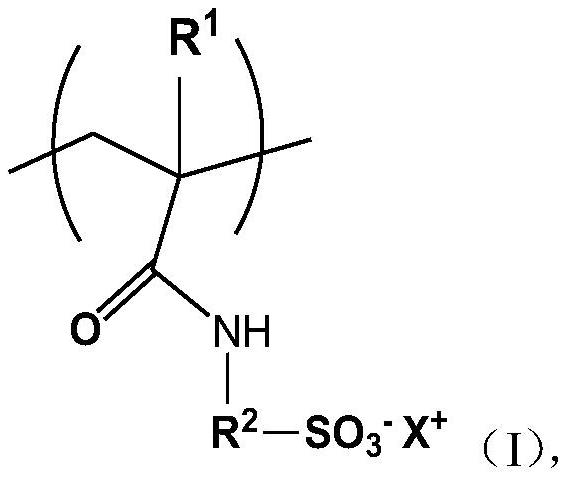

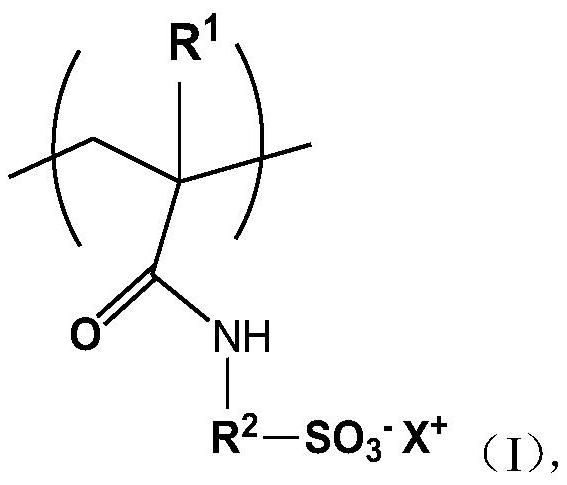

[0090] 20% of vinyl acetate (VAC) (630 L / hr), methanol (MeOH) (370 L / hr), and sodium 2-acrylamidotetradecanesulfonate as a modifier were continuously supplied to the polymerization tank using a quantitative pump. Mass % methanol solution (SEMA) (122 L / hr), and 2,2'-azobisisobutyronitrile in 2 mass % methanol solution (AIB) (25 L / hr).

[0091] Then, the polymerization liquid was continuously taken out from the polymerization tank so that the liquid level in the polymerization tank was kept constant. At this time, adjustment was made so that the polymerization rate of vinyl acetate in the polymerization liquid taken out from the polymerization tank became 40%. The residence time in the polymerization ...

Embodiment 2-3 and comparative example 1-4

[0097] Synthesis of PVA

[0098] Except the parameter shown in table 1, other is identical with embodiment 1, carries out the synthesis of modified PVA.

[0099] Table 1 embodiment 2-3 and comparative example 1-4 carry out the parameter of PVA synthesis

[0100]

[0101] Remarks: - indicates that the raw material has not been added.

[0102] Membrane production

[0103] A film was produced in the same manner as in Example 1 except that the modified PVA synthesized in Examples 1-3 and Comparative Examples 1-4 shown in Table 2 was used.

[0104] For the PVA and film obtained above, the PVA melt processability and the mechanical strength (Young's modulus and strength) of the film were measured or evaluated by the above method, and the results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com