Zirconium dioxide full porcelain tooth and preparation method thereof

A technology of zirconia and a manufacturing method, which is applied in the field of dentures, can solve the problems of unsuitability for porcelain casting repair, nickel allergy, damage to health and aesthetics, etc., to reduce the possibility of lesions, good biocompatibility, and prolong the life. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

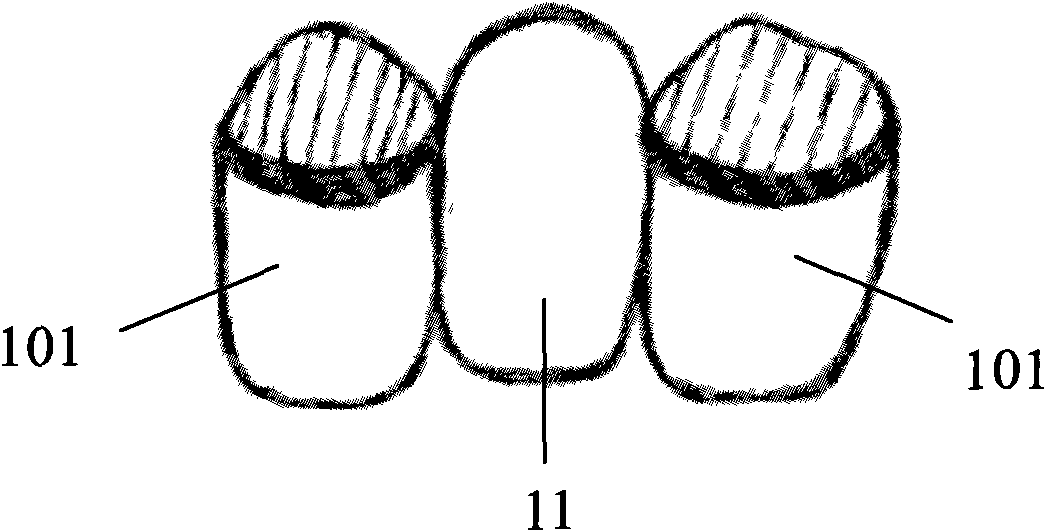

[0028] Such as figure 1 As shown, the present invention provides a zirconia all-ceramic tooth, including a fixed denture bridge structure, and a glazed porcelain layer (not shown) coated on the outer surface of the denture fixed bridge structure;

[0029] The denture fixed bridge structure is made of zirconia material, which includes several denture inner crowns 11 bonded to each other, and a support body 101 that can be sleeved and bonded to human teeth;

[0030] The inside of the support body 101 is hollow (as figure 1 Shown in the middle shadow), which are respectively connected to both sides of the inner crown 11 of the denture.

[0031] The hollow shape of the support body 101 fits the shape of the set human teeth. The teeth have been polished and their shape is smaller than normal teeth. The support body 101 is tightly and seamlessly bonded to the polished tooth with a medical adhesive. on the teeth;

[0032] The glazed porcelain layer adopts matching ceramic powder; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com