Super heat resistant ceramic wok and manufacturing method thereof

A technology of super heat-resistant ceramic products, applied in cooking utensils, household utensils, applications, etc., can solve the problems of difficult production and processing, ceramic cooking utensils bursting, etc., achieve excellent thermal shock resistance and inhibit grain growth , the effect of not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Use the following formula:

[0026] Spodumene 49%

[0027] Quartz 16%

[0028] Kaolin 19%

[0029] Talc 8%

[0030] Waste porcelain slag 7%

[0032] Polyacrylamine 0.5%

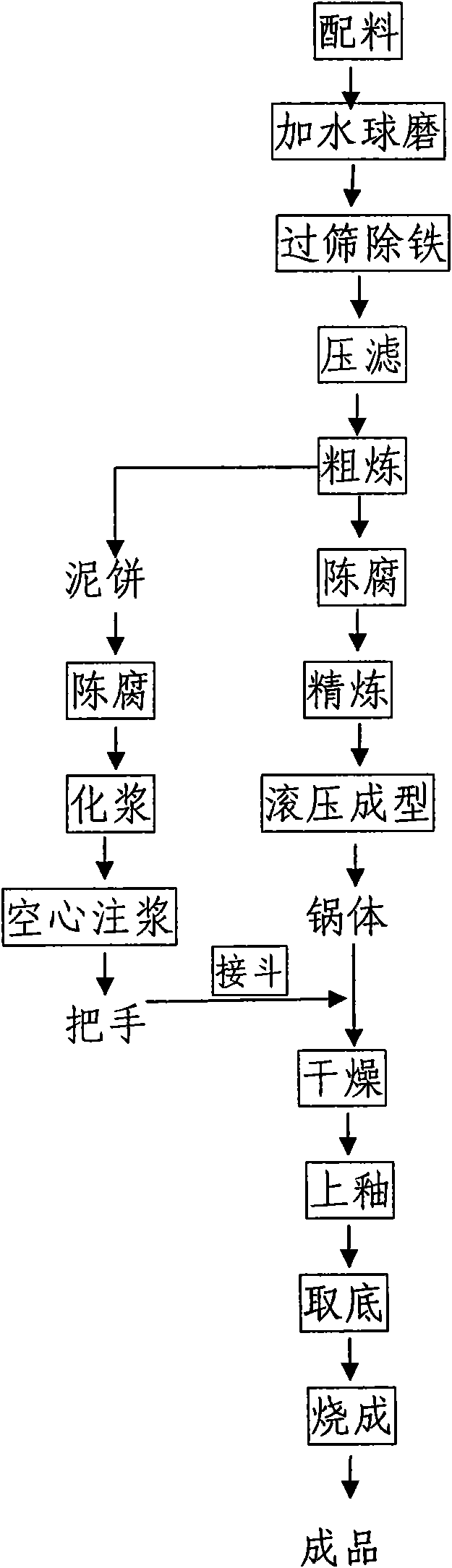

[0033] Adopting the process flow shown in the accompanying drawings, the highest firing temperature is 1320°C, the firing range is about 30°C, the cooling and holding temperature is 1150°C, and the holding time is 30 minutes, the product meeting the purpose of the present invention can be produced.

Embodiment 2

[0035] Use the following formula:

[0036] Spodumene 48%

[0037] Quartz 15%

[0038] Kaolin 20%

[0039] Talc 10%

[0040] Waste porcelain slag 6%

[0042] Polyacrylamide 0.3%

[0043] Adopting the process flow shown in the accompanying drawings, the highest firing temperature is 1320°C, the firing range is about 30°C, the cooling and holding temperature is 1150°C, and the holding time is 30 minutes, the product meeting the purpose of the present invention can be produced.

Embodiment 3

[0045] Use the following formula:

[0046] Spodumene 47%

[0047] Quartz 18%

[0048] Kaolin 19%

[0049] Talc 8.1%

[0050] Waste porcelain slag 6.5%

[0051] Niobium oxide 1%

[0052] Polyacrylamide 0.4%

[0053] Adopting the process flow shown in the accompanying drawings, the highest firing temperature is 1320°C, the firing range is about 30°C, the cooling and holding temperature is 1150°C, and the holding time is 30 minutes, the product meeting the purpose of the present invention can be produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com