Method for mineralizing and degrading organic waste water and processing equipment

A technology for organic wastewater and wastewater treatment, which is applied in the directions of oxidized water/sewage treatment, light water/sewage treatment, added substance water/sewage treatment, etc. It can solve the problems of low wastewater treatment efficiency, limited wastewater treatment capacity, and difficulty in scaling up equipment, etc. problems, to achieve the effect of low cost, low maintenance cost, and fewer processing units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

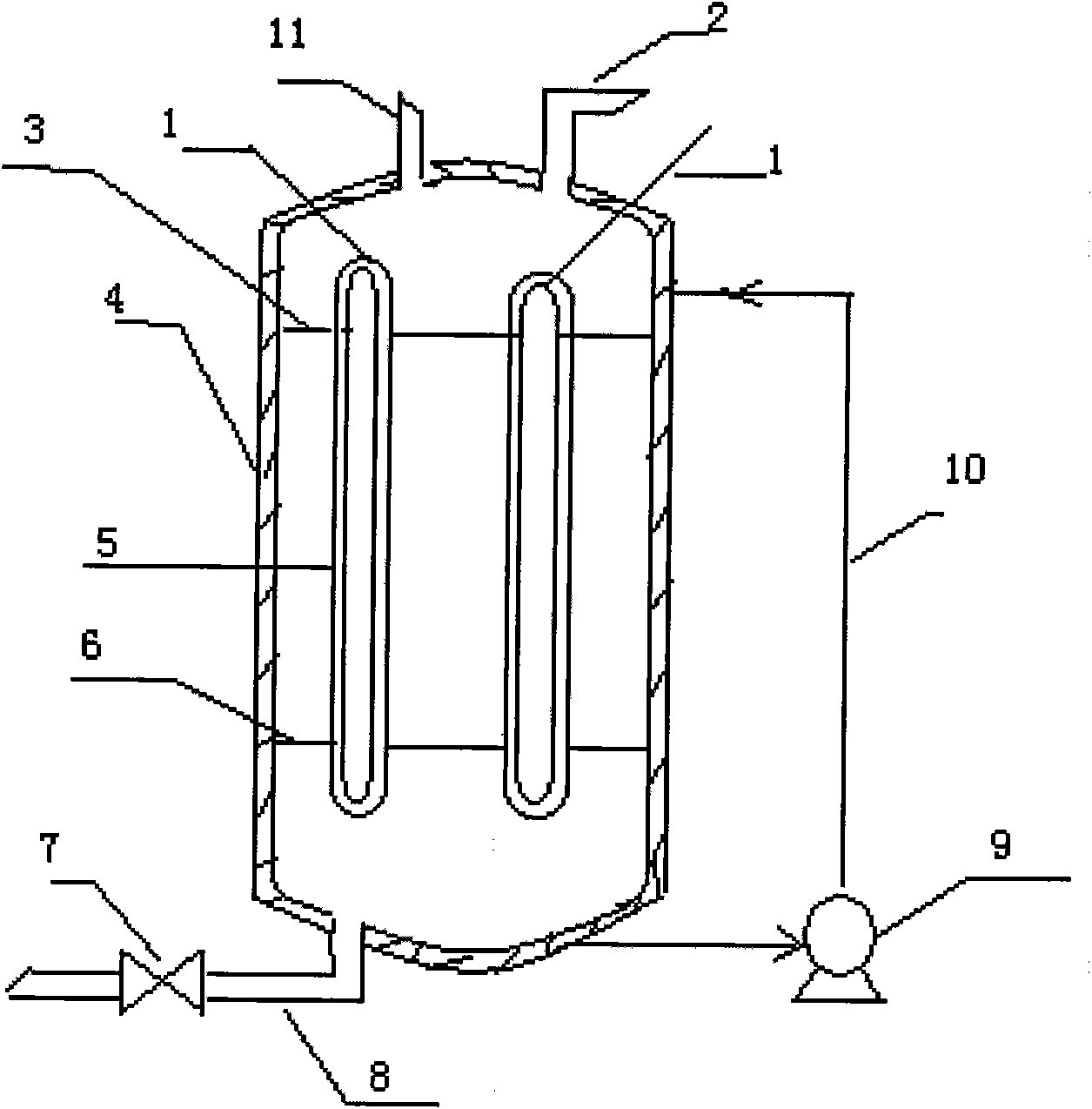

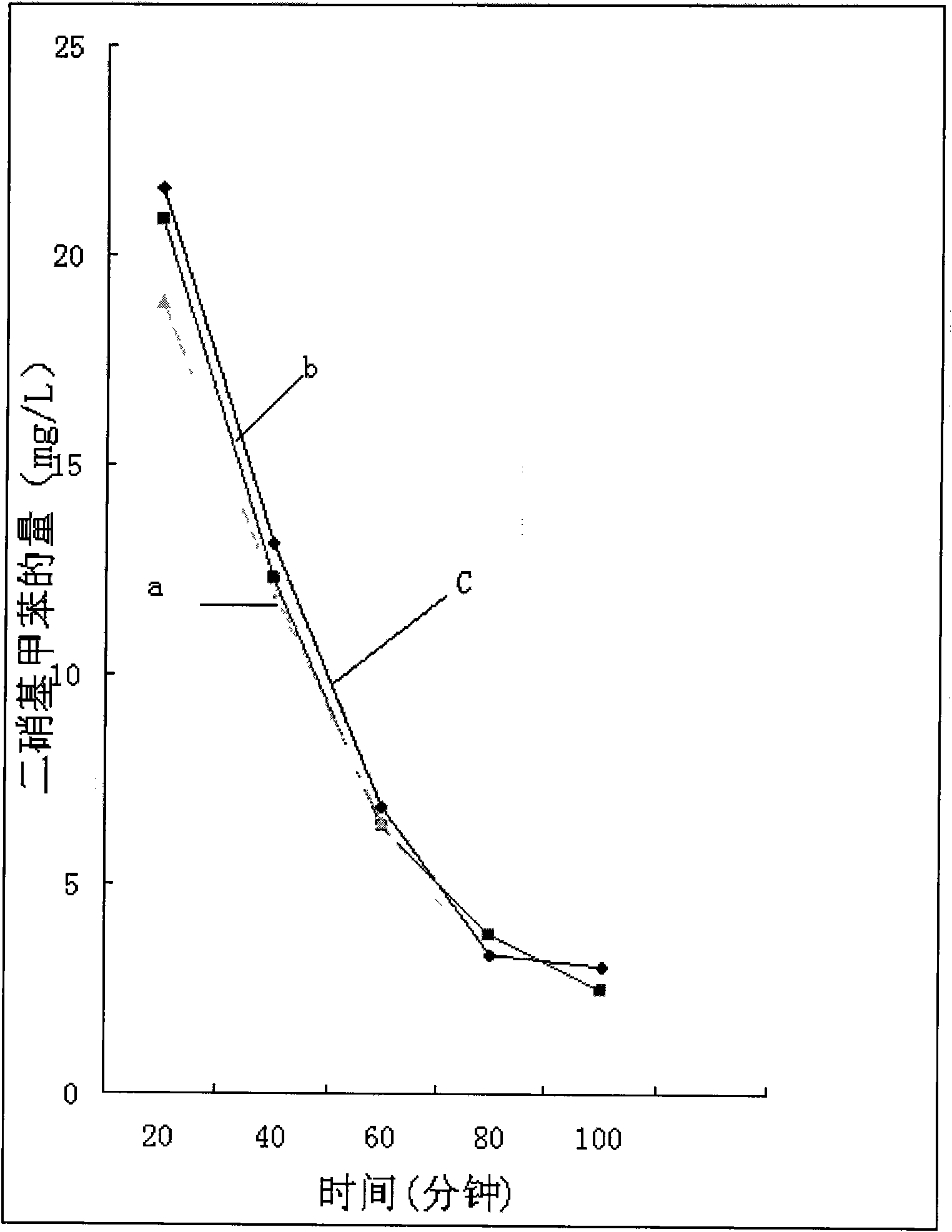

[0034] The wastewater treated in this embodiment is an aqueous solution containing dinitrotoluene, and the content of dinitrotoluene is 29.80 mg / L. 0.5 grams of nano-scale platinum and 10 mL of hydrogen peroxide are selected, and the amount of wastewater to be treated is 2 liters. First, waste water is added to the treatment equipment through the water inlet pipe 10, and then the catalyst is added to the waste water through the water inlet pipe 10; the circulation pump 9 is started, the light source is turned on to make the quartz tube and the ultraviolet lamp 5 emit light; the power is 10000W; the wavelength is 100-800nm, The organic matter in the wastewater begins to be degraded, and the exhaust gas is discharged from the pipe at the top. Take a water sample at regular intervals, such as every 20 minutes, and measure the content of dinitrotoluene with a high-performance liquid chromatograph. After the COD reaches the standard, the treated water is discharged from the drain ...

Embodiment 2

[0037] The wastewater treated in this embodiment is the same dinitrotoluene-containing aqueous solution as in Example 1, and the content of dinitrotoluene is 29.80 mg / L. 0.5 grams of nano-scale silver and 10 mL of hydrogen peroxide are selected to treat 2 liters of waste water. Processing method is identical with embodiment 1.

[0038] List the content of dinitrotoluene contained in water at different times, and draw the relationship between the content of dinitrotoluene and time, such as figure 2 In the b line shown. The content of dinitrotoluene after treatment was 2.4mg / L. The results show that the catalytic system can effectively degrade dinitrotoluene, and make the content of dinitrotoluene in water lower than the emission standard stipulated by the state.

Embodiment 3

[0040] The wastewater treated in this embodiment is the same dinitrotoluene-containing aqueous solution as in Example 1, and the content of dinitrotoluene is 29.80 mg / L. A combination of 0.5 grams of nano-scale silver and ozone is selected as a catalyst, and the amount of wastewater treated is 2 liters. Processing method is identical with embodiment 1.

[0041] List the content of dinitrotoluene contained in water at different times, and draw the relationship between the content of dinitrotoluene and time, such as figure 2 Shown in line c. The content of dinitrotoluene after treatment was 3.6mg / L. The results show that the catalytic system can effectively degrade dinitrotoluene, and the content of dinitrotoluene in water is lower than the national emission standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com