Red light or infrared light catalytic material comprising semiconductor material and up-conversion material

A technology for conversion materials and catalytic materials, which is applied in the field of new red light or infrared photocatalytic materials, and can solve the problems that light energy cannot be effectively used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

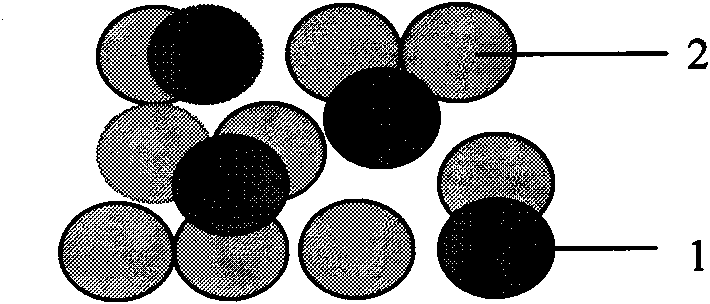

[0025] Example 1: Er-doped Y 3 al 5 o 12 Upconversion materials and TiO 2 Red light photocatalytic material mixed with semiconductor materials

[0026] 1. Sample Preparation Process

[0027] 1) Preparation of Er-doped Y by sol-gel method 3 al 5 o 12 Nanoparticles. According to molar ratio 0.05Er 3+ : 2.95Y 3+ : 5.00Al 3+ Weigh 0.019g of Er 2 o 3 , 0.666g of Y 2 o 3 and 0.510g of Al 2 o 3 Dissolve together in 20mL of nitric acid with a concentration of 10%, put the solution on an electric stove and heat to evaporate excess water and nitric acid to obtain 2.2g of nitrate mixture; then dissolve the obtained nitrate mixture in 20ml of deionized water, and then add Add 2ml of ethylene glycol and 2ml of acetic acid, stir the resulting solution for 10h to form a transparent jelly, dry the gel at 100°C to obtain a white powder, and then anneal the obtained white powder at 600°C for 2 hours That is to get 1g up-conversion material Y 2.95 Er 0.05 al 5 o 12 , where t...

Embodiment 2

[0036] Example 2: Er-doped Y 3 al 5 o 12 up-conversion material and V 2 o 5 Red light photocatalytic material mixed with semiconductor materials

[0037] 1. Sample Preparation Process

[0038] 1) Er-doped Y 3 al 5 o 12 The preparation is the same as in Example 1.

[0039] 2) take ammonium vanadate as raw material to prepare V 2 o 5 , Dissolve 0.5g of ammonium vanadate in 60ml of deionized water, then put the solution in a drying oven and dry at 120°C for 12h, and then sinter the dried product at 450°C for 4h in an air atmosphere to obtain 0.6g of V 2 o 5 , place 0.45g of V 2 o 5 with 0.05g Y 2.95 Er 0.05 al 5 o 12 After mixing and grinding, a red-light photocatalytic material is obtained, wherein V 2 o 5 The quality score is 90%.

[0040] 2. Carry out the red light photocatalytic activity test, the test process is the same as that of Example 1.2, and the experimental results are shown in the table below.

[0041] Table 3: Data on the degradation of methyle...

Embodiment 3

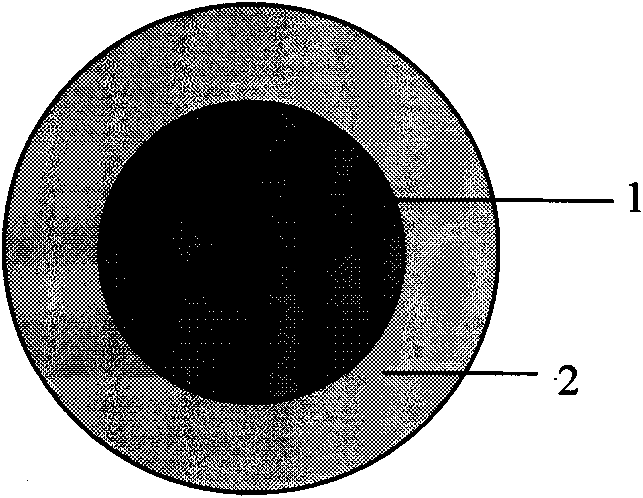

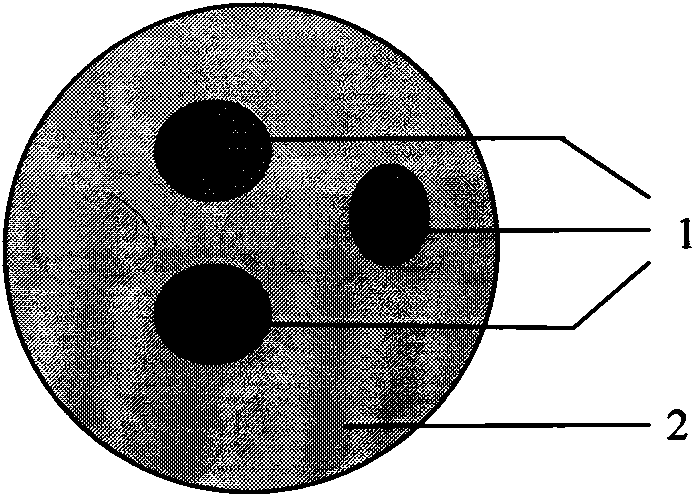

[0046] Example 3: YF co-doped with Yb and Tm 3 Upconversion materials and TiO 2 Hybrid Core-Shell Structured Infrared Photocatalytic Materials

[0047] 1. Sample Preparation Process

[0048] 1) Synthesis of Yb and Tm co-doped YF by hydrothermal method 3 . Weigh Y according to molar ratio 0.795Y: 0.2Yb: 0.005Tm 2 o 3 0.09g, Yb 2 o 3 0.394g and Tm 2 o 3 Dissolve 0.01g together in 20mL, 7% dilute hydrochloric acid, heat to dissolve, continue heating to evaporate excess solvent until white Y is obtained 0.795 Yb 0.2 T m 0.005 Cl 3 powder, dissolve the obtained chloride in 20ml of deionized water, then add 3ml of hydrofluoric acid, stir for 1 hour, then transfer the sample to a hydrothermal reaction kettle, keep it at 130°C for 12 hours, cool to room temperature, and then centrifugally clean the sample , placed in a vacuum drying oven at 60°C for 6 hours, and finally placed in a tube furnace and annealed at 600°C for 6 hours under an argon protective atmosphere to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com