Preparation method of small-sized NaYF4 nano substrate material with hexagonal phase by inducement

A nano-matrix and hexagonal phase technology, applied in the field of nano-materials, can solve problems such as difficult complete conversion, complicated methods, and affecting the up-conversion luminescence performance of fluoride nanoparticles, and achieves high repeatability, uniform particle size, and good dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Prepare various reaction reagent solutions. Weigh 12.1306 grams of yttrium chloride, add 80ml of ethylene glycol, and stir until dissolved. The ethylene glycol solution of yttrium chloride prepared at this time is preserved as a storage solution, and the concentration of yttrium ions in the solution is 0.5mol / L. As above, weigh 1.528 grams of erbium chloride, 7.7472 grams of ytterbium chloride, 3.0663 grams of thulium chloride, 31.16 grams of lutetium chloride, and 4.675 grams of sodium chloride, and add 80ml of ethylene glycol to make the concentration 0.05mol / L respectively , 0.25mol / L, 0.1mol / L, 1mol / L, 1mol / L ethylene glycol solutions of various chlorides.

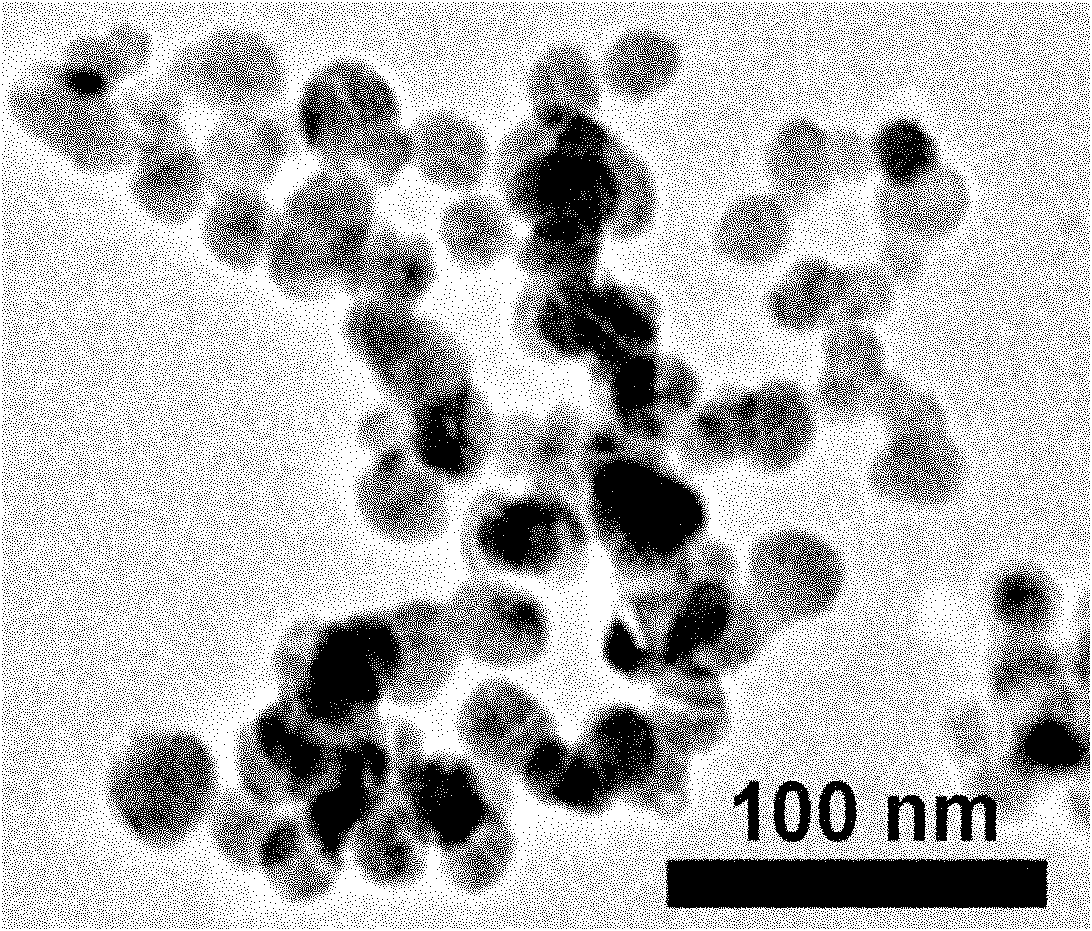

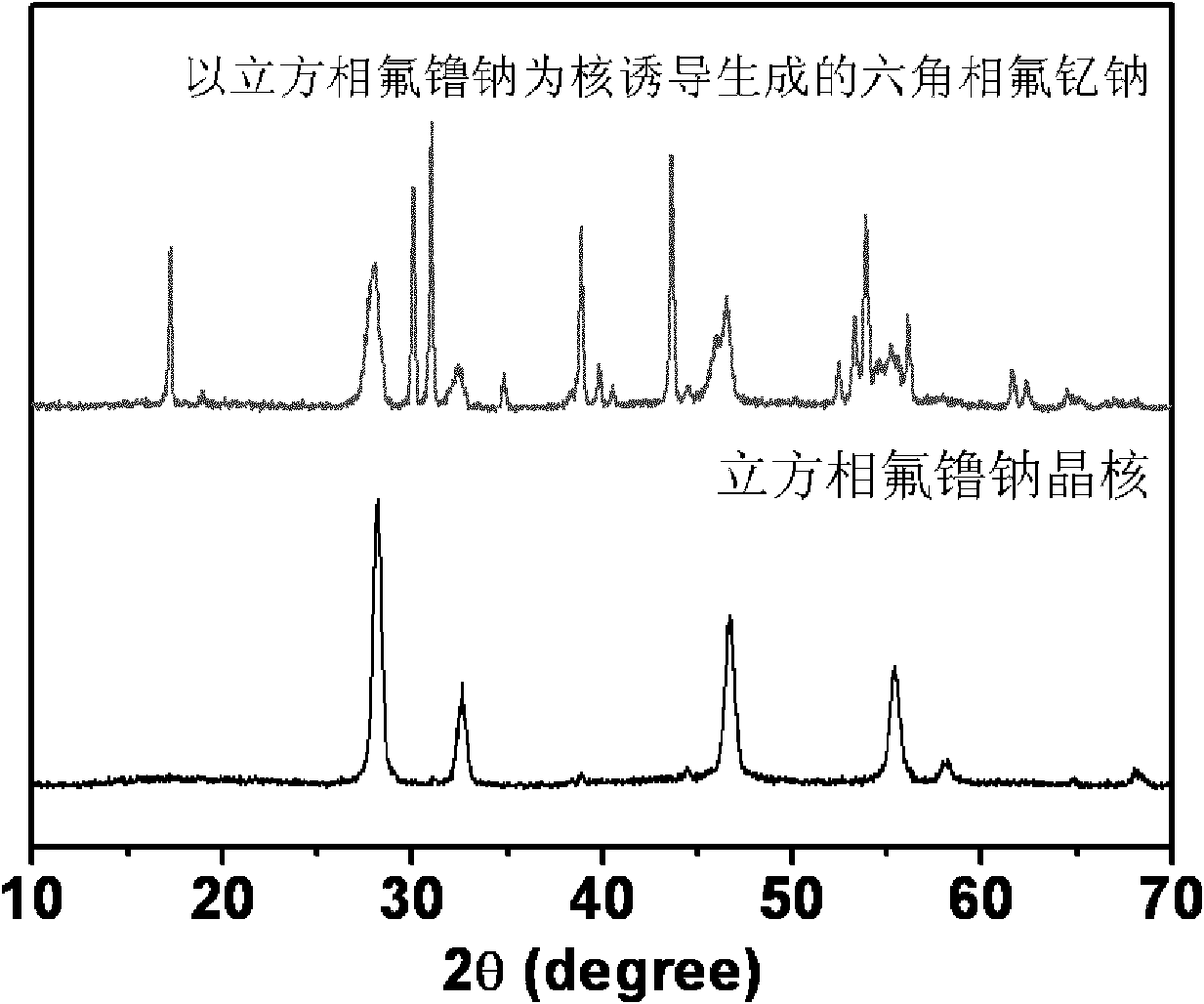

[0039] (2) Preparation Using ethylene glycol as a solvent to prepare rare earth fluoride nanocrystal nuclei by solvothermal method. Take by weighing 0.5 gram of surfactant PVP, add 8ml of ethylene glycol, stir until dissolving, take lutetium chloride solution 1ml prepared in step (1) in proportion, sodium c...

Embodiment 2

[0043] (1) With embodiment 1 step (1).

[0044] (2) Preparation Using ethylene glycol as a solvent to prepare rare earth fluoride nanocrystal nuclei by solvothermal method. Weigh 0.5 gram of surfactant PVP, add 8ml of ethylene glycol, stir until dissolved, take 1ml of lutetium chloride solution and 1ml of sodium chloride solution prepared in step (1) in proportion and add them to the PVP solution, and stir magnetically at room temperature 1 hour. Add 8 ml of ethylene glycol solution containing 0.56 g of potassium fluoride, and stir for 30 minutes. The above mixed solution was transferred to a reaction kettle, the temperature was 180 degrees Celsius, and the reaction time was 24 hours. After the reaction, the dispersed NaLuF 4 Ethylene glycol solution of nanocrystals. NaLuF 4 The nanocrystals are pure cubic phase with an average particle size of 25nm.

[0045] (3) The rare earth fluoride nanocrystal nucleus prepared in step (2) induces the generation of small-sized, hexag...

Embodiment 3

[0048] (1) With embodiment 1 step (1).

[0049] (2) Preparation Using ethylene glycol as a solvent to prepare rare earth fluoride nanocrystal nuclei by solvothermal method. Take by weighing 0.5 gram of surfactant PVP, add 8ml ethylene glycol, stir until dissolving, take lutetium chloride solution 1ml prepared in step (1), sodium chloride solution 1ml in proportion and add in the PVP solution, under normal temperature magnetic stirring 1 Hour. Add 8 ml of a solution of 0.56 g of potassium fluoride in 4 ml of ethylene glycol and stir for 30 minutes. The above mixed solution was transferred to a reaction kettle, the temperature was 180 degrees Celsius, and the reaction time was 24 hours. After the reaction, the dispersed NaLuF 4 Ethylene glycol solution of nanocrystals. NaLuF 4 The nanocrystals are pure cubic phase with an average particle size of 25nm.

[0050] (3) The rare earth fluoride nanocrystal nucleus prepared in step (2) induces the generation of small-sized, hexag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com