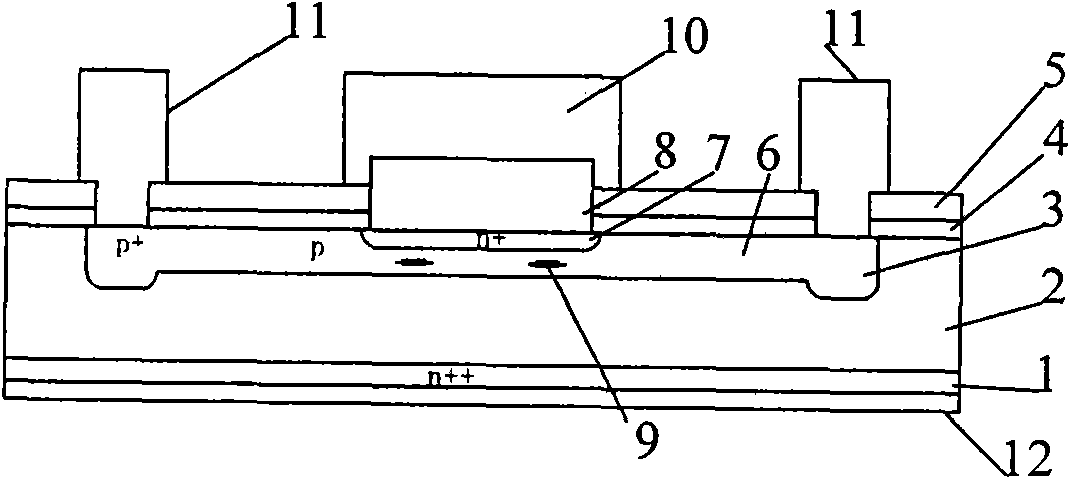

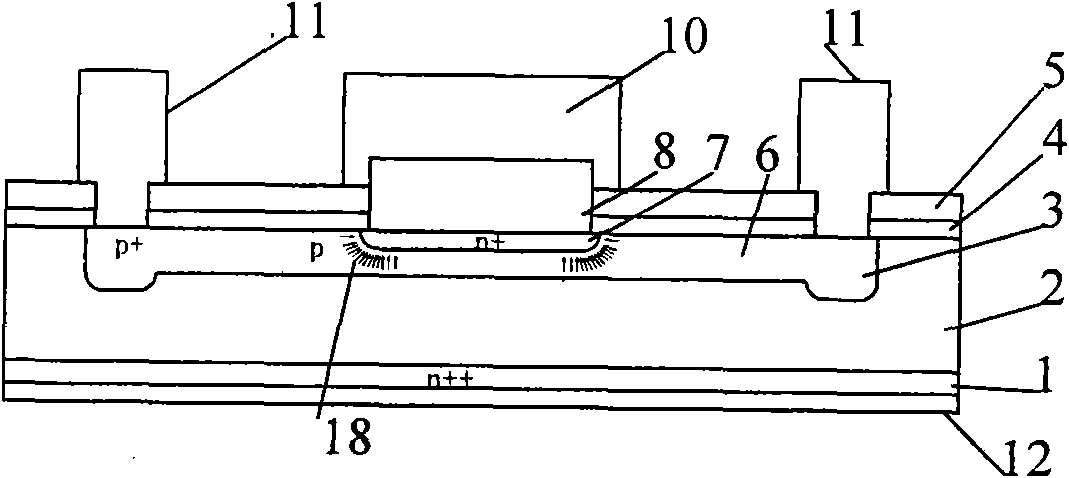

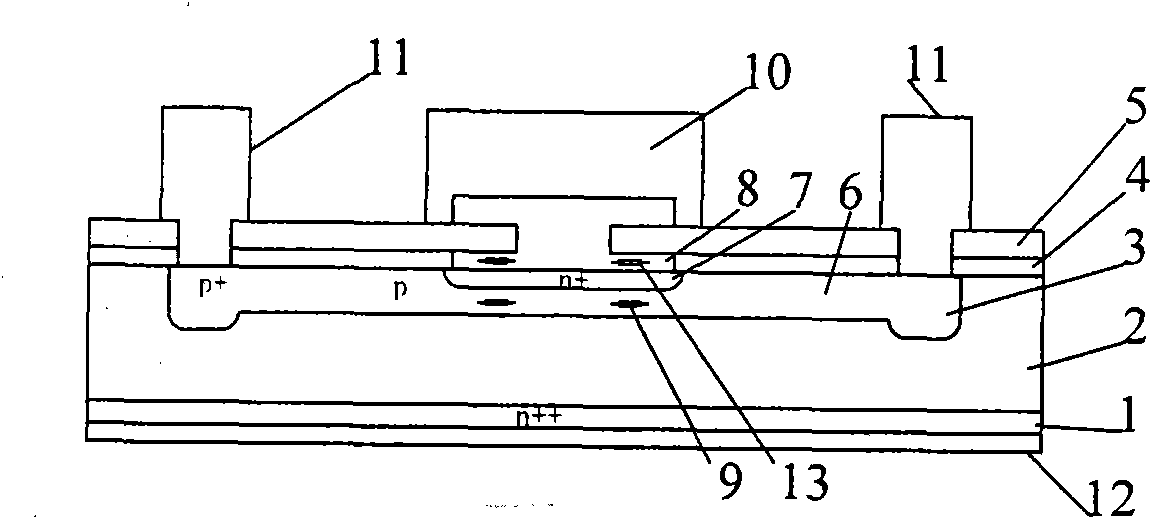

Structure and method for improving current crowding effect of microwave power transistor emitter region

A technology of microwave power and emission area, applied in the direction of transistors, circuits, electrical components, etc., can solve the problems of limiting chip output power, reducing the width of the emission area, affecting the processing yield, etc., to reduce the difference in voltage drop, Reduce process difficulty and improve the effect of microwave output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1) Select an arsenic-doped silicon substrate region with a thickness of 380 μm and a resistivity of ≤0.003Ω·cm, and its silicon epitaxial layer is doped with phosphorus (n-type), with a resistivity of 0.75Ω·cm and a thickness of 1 μm (attached Figure 5 );

[0059] 2) Coating a layer of photoresist film on the surface of the silicon substrate with a thickness of 1.0 μm (attached Figure 6 );

[0060] 3) Selectively expose and develop the photoresist to obtain a window in the base contact area, and then perform B in the window by using an ion implantation process. + (or BF 2 + ) doping to form p + doped region (attached Figure 7 );

[0061] 4), using dry or wet process to remove the attached Figure 5 The photoresist in the photoresist, and then re-coat a layer of photoresist film on the surface of the silicon substrate, with a thickness of 1.0 μm; selectively expose and develop the photoresist to form a base injection window (attached Figure 8 );

[0062] 5) Pe...

Embodiment 2

[0074] 1) Select an arsenic-doped silicon substrate region with a thickness of 470 μm and a resistivity of ≤0.003Ω·cm, and its silicon epitaxial layer is doped with phosphorus (n-type), with a resistivity of 1.125Ω·cm and a thickness of 8 μm (attached Figure 5 );

[0075] 2) Coating a layer of photoresist film on the surface of the silicon substrate with a thickness of 1.75 μm (attached Figure 6 );

[0076] 3) Selectively expose and develop the photoresist to obtain a window in the base contact area, and then perform B in the window by using an ion implantation process. + (or BF 2 + ) doping to form p + doped region (attached Figure 7 );

[0077] 4), using dry or wet process to remove the attached Figure 5 The photoresist in the photoresist, and then re-coat a layer of photoresist film on the surface of the silicon substrate, with a thickness of 1.75 μm; selectively expose and develop the photoresist to form a base injection window (attached Figure 8 );

[0078] 5)...

Embodiment 3

[0088] 1) Select an arsenic-doped silicon substrate region with a thickness of 560 μm and a resistivity of ≤0.003Ω·cm, whose silicon epitaxial layer is doped with phosphorus (n-type), with a resistivity of 1.5Ω·cm and a thickness of 15 μm (attached Figure 5 );

[0089] 2) Coating a layer of photoresist film on the surface of the silicon substrate with a thickness of 2.5 μm (attached Figure 6 );

[0090] 3) Selectively expose and develop the photoresist to obtain a window in the base contact area, and then perform B in the window by using an ion implantation process. + (or BF 2 + ) doping to form p + doped region (attached Figure 7 );

[0091] 4), using dry or wet process to remove the attached Figure 5 The photoresist in the photoresist, and then re-coat a layer of photoresist film on the surface of the silicon substrate, with a thickness of 2.5 μm; selectively expose and develop the photoresist to form a base injection window (attached Figure 8 );

[0092] 5) Perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com