Detection method of lead content in gasoline

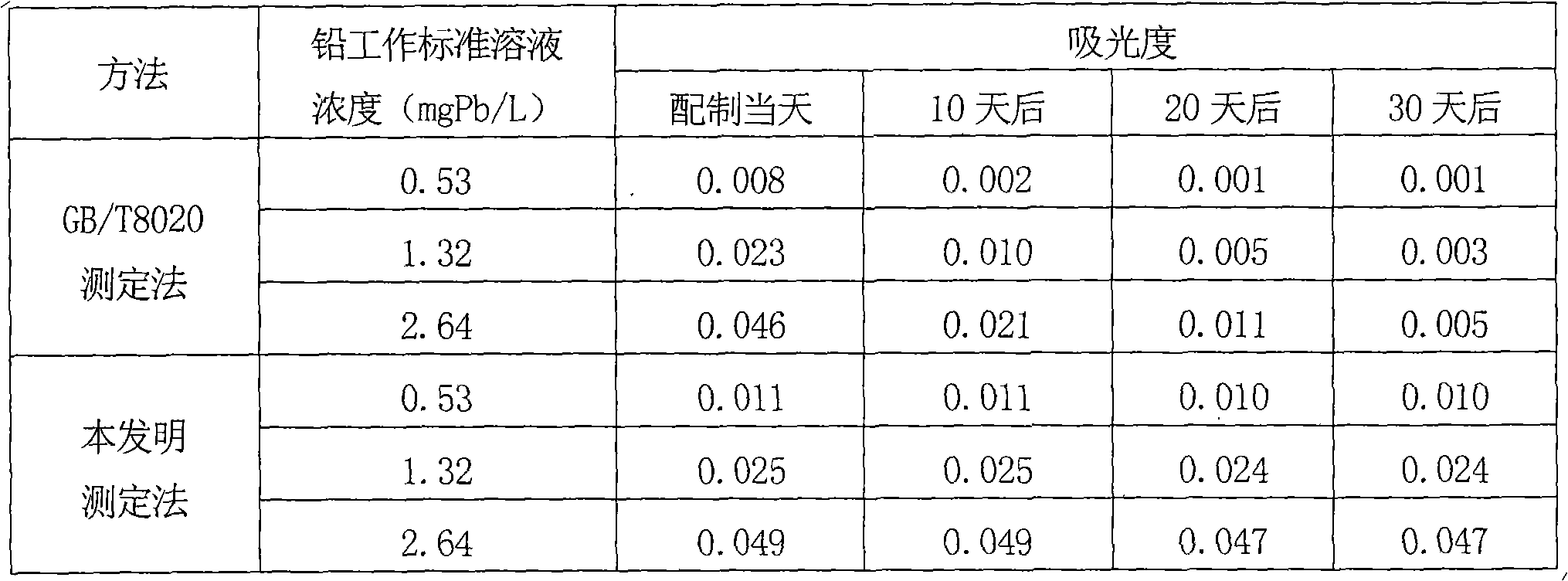

A detection method and technology of lead content, which is applied in the field of detection of lead content in gasoline, can solve the problems of threatening the health of the operator, failure to meet the lower limit of detection, failure to use again, etc., to achieve extended stable storage time, reduce the number of preparations, and avoid pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Prepare the solution

[0024] Use methyl trioctyl ammonium chloride and methyl isobutyl ketone according to conventional methods to prepare a 10% methyl trioctyl ammonium chloride-methyl isobutyl ketone solution; use iodine and toluene to prepare a mass concentration of Iodine-toluene solution with a concentration of 3.0%; glacial acetic acid-methyl isobutyl ketone solution with a mass concentration of 3.0% was prepared with glacial acetic acid and methyl isobutyl ketone.

[0025] 2. Preparation of lead standard solution

[0026] (1) According to the GB / T8020 gasoline lead content determination method, that is, the atomic absorption spectrometry preparation concentration is 1321mgPb / L lead-methyl trioctyl ammonium chloride-methyl isobutyl ketone lead standard solution, diluted to mass with this standard solution The concentration is 264mgPb / L lead-methyl trioctylammonium chloride-methyl isobutyl ketone lead standard solution.

[0027] (2) prepare three kinds of lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com