Electrolyte for lithium-ion power battery and preparation method thereof

A power battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of low content, the impact of battery cycle life, and the limited improvement of power battery life, so as to improve high-temperature conductivity and facilitate transmission. Full effect on de-intercalation, capacity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

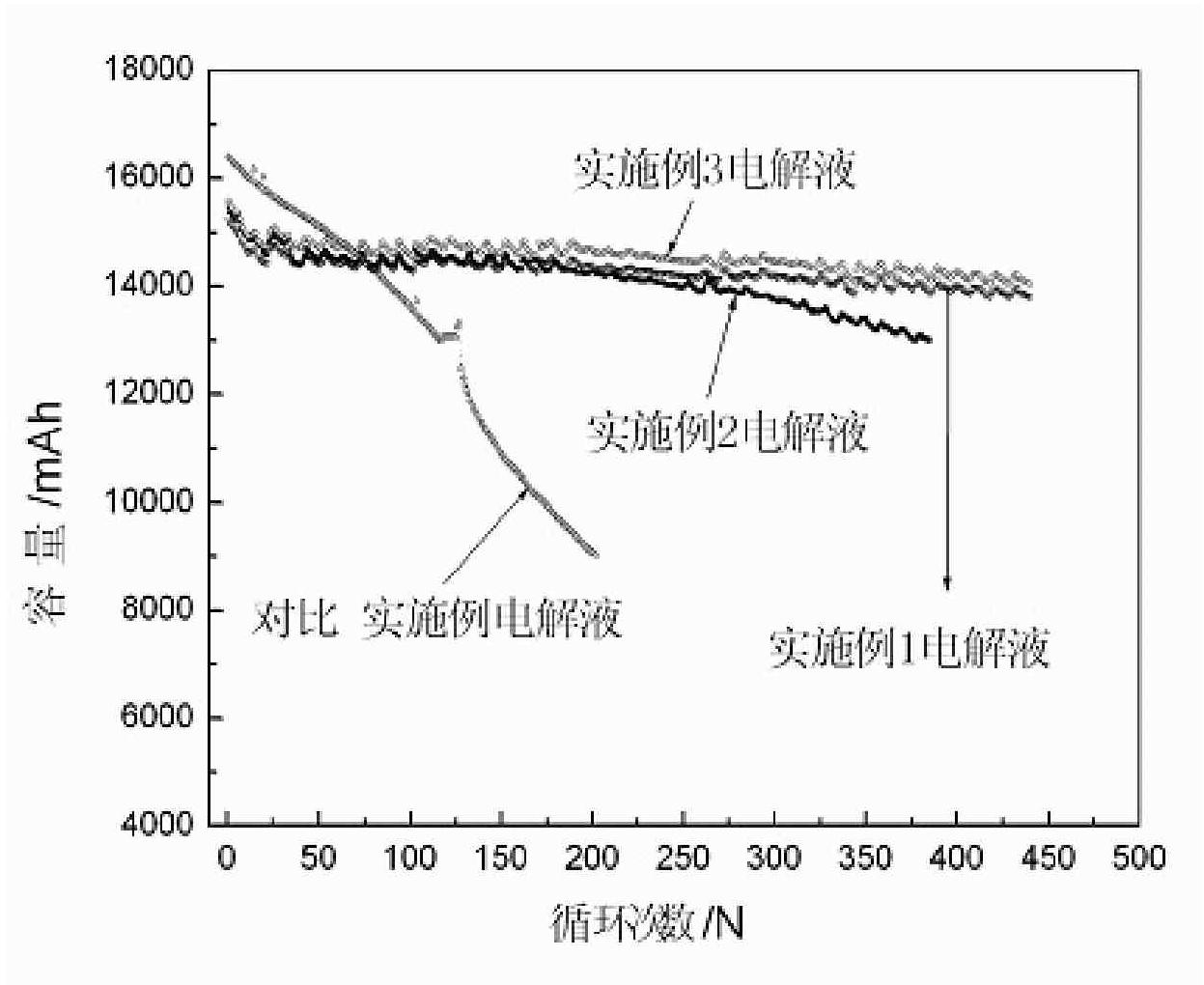

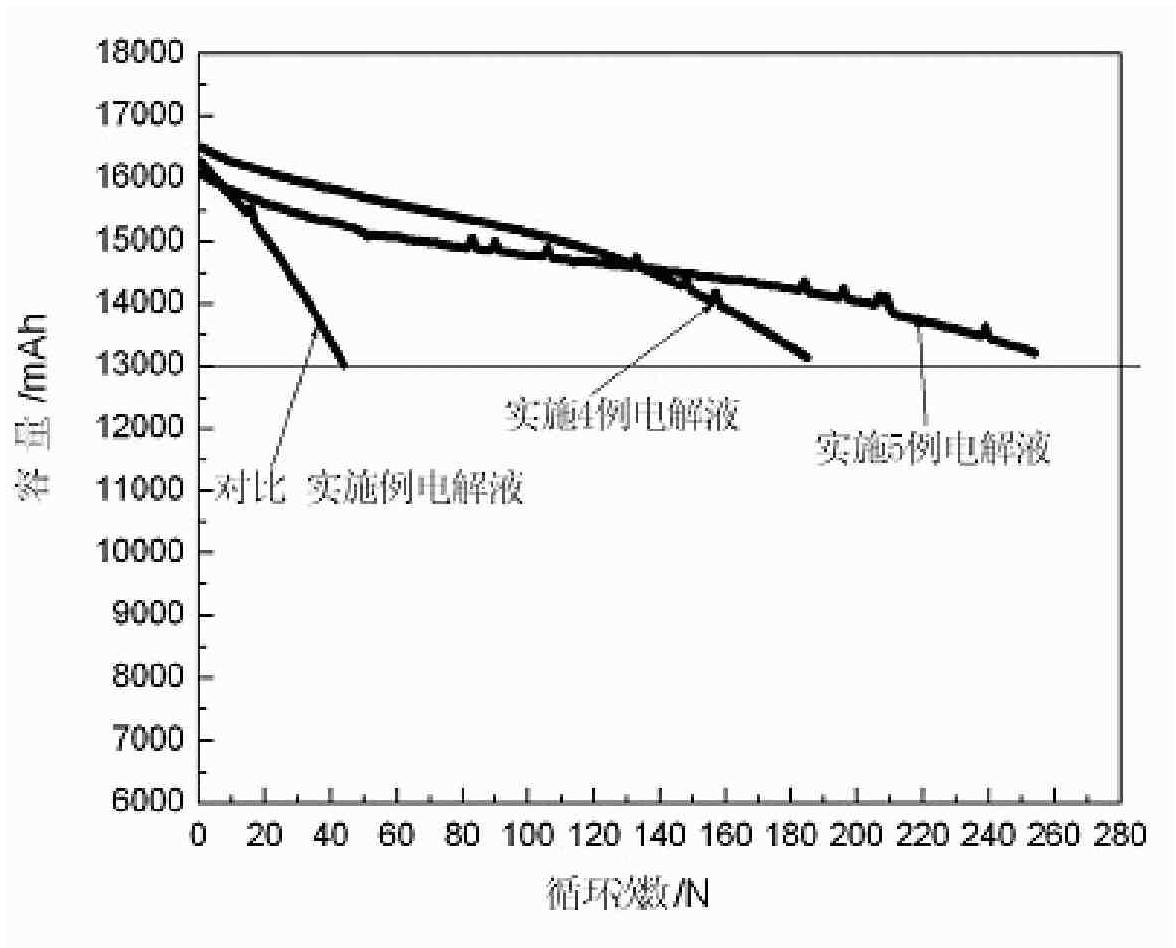

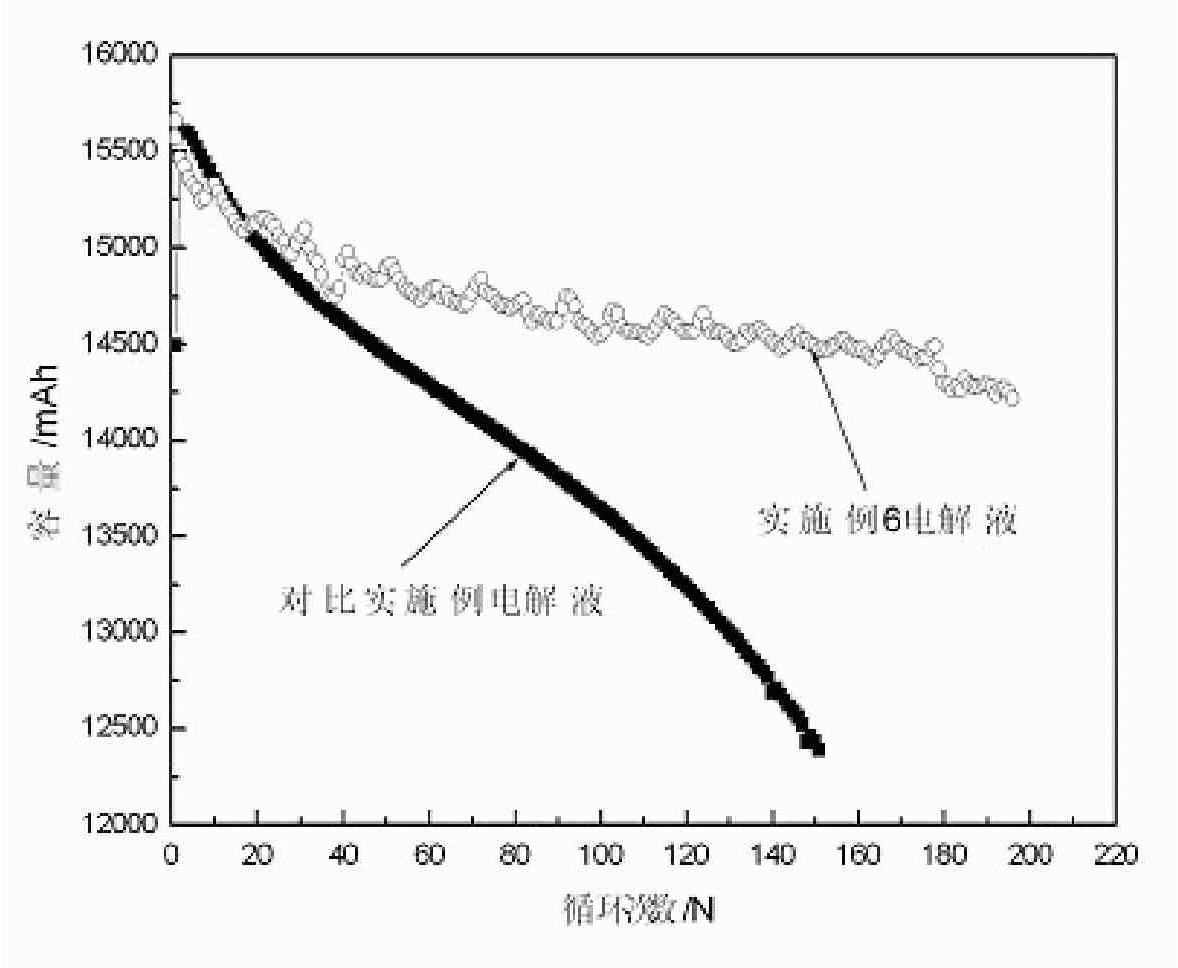

Embodiment 1

[0049] The first step is to use a rotary evaporator to distill and purify the organic solvents EC, PC, DMC, and EA at 25°C to remove trace water inside, and then use 4A molecular sieves to deeply absorb trace water at 40°C. . This operation is repeated three times until the impurity and water content are less than 0.002%. Then weigh a certain amount of EC, PC, DMC and EA with a microanalytical electronic balance, the mass ratio of the four of them is 3:3:1:1, EC, PC, DMC and EA are mixed with quaternary solvents, and mixed with a graduated cylinder (250ml) Measure 100g of mixed organic solvent and pour it into a grinding bottle. All processes in the preparation of the electrolyte were carried out in a glove box filled with high-purity argon.

[0050] The second step is to weigh 10g LiODFB and 3g LiPF with a microanalytical electronic balance in the glove box at 25°C 6 , and then add it in the above-mentioned quaternary mixed solvent (in the grinding bottle), fully stir even...

Embodiment 2

[0053] The first step is to use a rotary evaporator to distill and purify the organic solvents EC, EMC, and EA at 25°C to remove trace water inside, and then use 4A molecular sieves to deeply absorb trace water at 40°C. This operation is repeated three times until the impurity and water content are less than 0.002%. Then take a certain amount of EC, EMC, and EA with a microanalytical electronic balance, wherein the mass ratio of the three is 5:3:2, EC, EMC, and EA are mixed with a ternary solvent, and 100g is measured with a graduated cylinder (250ml) Pour the mixed organic solvents into the grinding bottle. All processes in the preparation of the electrolyte were carried out in a glove box filled with high-purity argon.

[0054] The second step is to weigh 10g LiODFB and 2g LiBF with a microanalytical electronic balance in the glove box at 25°C 4 , and then add it to the above-mentioned ternary mixed solvent (in the ground-mouth bottle), fully stir until the solution is cle...

Embodiment 3

[0057] In the first step, under the condition of 25°C, the organic solvents EC, DEC, and EA were firstly distilled and purified by a rotary evaporator to remove trace water inside, and then the trace water was deeply adsorbed by 4A molecular sieves at 40°C. This operation is repeated three times until the impurity and water content are less than 0.002%. Then take a certain amount of EC, DEC, and EA with a microanalytical electronic balance, wherein the mass ratio of the three is 4:3:1, EC, DEC, and EA are mixed with ternary solvents, and a graduated cylinder (250ml) measures 100g of mixed Pour the organic solvent into the grinding bottle. All processes in the preparation of the electrolyte were carried out in a glove box filled with high-purity argon.

[0058] The second step is to weigh 7g LiODFB and 6gLiN(SO 2 CF 3 ) 2 , and then add it to the above-mentioned ternary mixed solvent (in the ground-mouth bottle), fully stir until the solution is clear and free of precipitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com