Micro-wave on-wafer testing method based on unknown material substrate

A test method, microwave technology, applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve problems such as reference impedance uncertainty, and achieve the effects of avoiding error accumulation, high test accuracy, and convenient data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

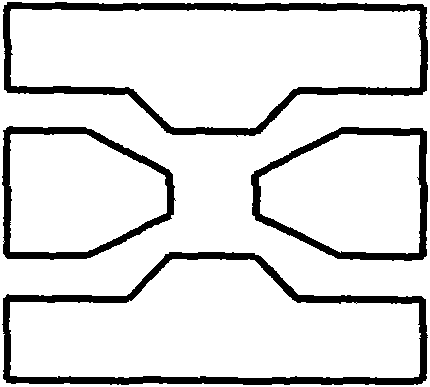

[0047] 1), the substrate structure is: 360um sapphire + 2um gallium nitride (GaN) + 0.15um barium strontium titanate (BST), the dielectric constant of the sapphire substrate is 5.5, the dielectric constant of GaN is 9.0, and the dielectric constant of BST is unknown . Manufactured by integrated circuit thin film technology figure 1 , figure 2 , image 3 , Figure 4 Medium TRL calibration kit, Figure 5 open resonator and Image 6 All patterns of the components under test adopt CPW structure, in which the line width is 120um, the gap is 25um, the length of the straight line is 250um, the lengths of the two long lines are 2090um and 3810um respectively, and the length of the open line is 1630um.

[0048] 2), use the TRL full two-port calibration function of the vector network analyzer to calibrate the microwave on-chip test system, and the calibration parts are prepared in step 1. figure 1 , figure 2 , image 3 , Figure 4 TRL calibration parts;

[0049] 3), will F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com