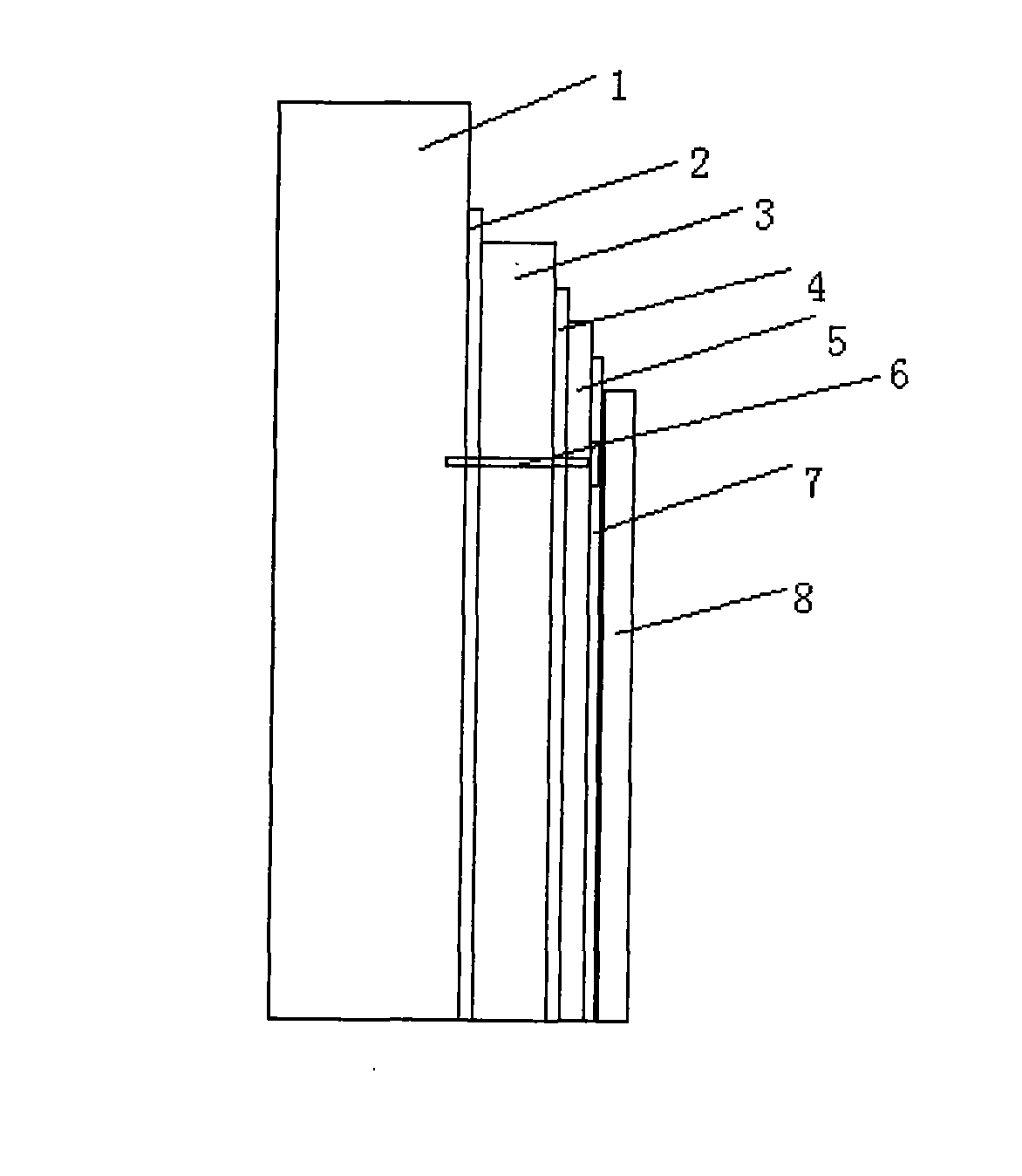

External insulating system for thinly plastered external wall of extruded polystyrene board

A technology of extruded polystyrene board and external wall insulation, which is applied in thermal insulation, building components, climate change adaptation, etc., can solve problems such as water absorption, air leakage and poor compressive strength, and achieve low energy consumption and excellent thermal insulation Effect of thermal function, good occupant comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0034] Example 1: Take Portland cement 250kg, fly ash 30kg, ash calcium powder 25kg, calcium carbonate powder 51kg, quartz sand 600kg, polymer redispersible latex powder 40kg, methyl cellulose ether 2kg, polyvinyl alcohol wrapped silane Powder 1kg, modified starch ether 1kg.

example 2

[0035] Example 2: Take Portland cement 339kg, fly ash 30kg, ash calcium powder 15kg, calcium carbonate powder 30kg, quartz sand 550kg, polymer redispersible latex powder 30kg, methyl cellulose ether 3kg, polyvinyl alcohol wrapped silane Powder 2kg, modified starch ether 1kg.

example 3

[0036] Example 3: Take Portland cement 350kg, fly ash 30kg, ash calcium powder 15kg, calcium carbonate powder 40kg, quartz sand 524kg, polymer redispersible latex powder 35kg, methyl cellulose ether 3kg, polyvinyl alcohol wrapped silane Powder 2kg, modified starch ether 1kg.

[0037] Preparation of anti-crack mortar for extruded board:

[0038] Example 1: Take Portland cement 250kg, silica fume 15kg, slaked lime 8kg, calcium carbonate powder 120kg, quartz sand 554kg, polymer redispersible latex powder 45kg, methyl cellulose ether 3kg, polyvinyl alcohol wrapped silane powder 3kg, Modified starch ether 0.5kg, wood fiber 1kg, polypropylene crack-resistant fiber 0.5kg.

[0039] Example 2: Take Portland cement 300kg, silica fume 5kg, slaked lime 2kg, calcium carbonate powder 80kg, quartz sand 572kg, polymer redispersible latex powder 35kg, methyl cellulose ether 2kg, polyvinyl alcohol wrapped silane powder 2kg, Modified starch ether 0.5kg, wood fiber 1kg, polypropylene crack-resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com