Circuit structure for collecting sensor signal of catalytic combustion type fuel gas

A gas sensor and acquisition circuit technology, applied in the direction of material resistance, etc., can solve problems such as danger, sensor zero drift cannot determine the progressive zero drift and zero drift range, single-chip microcomputer can not determine the real zero point of the sensor, etc., to eliminate safety hazards and reduce production /debugging the effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

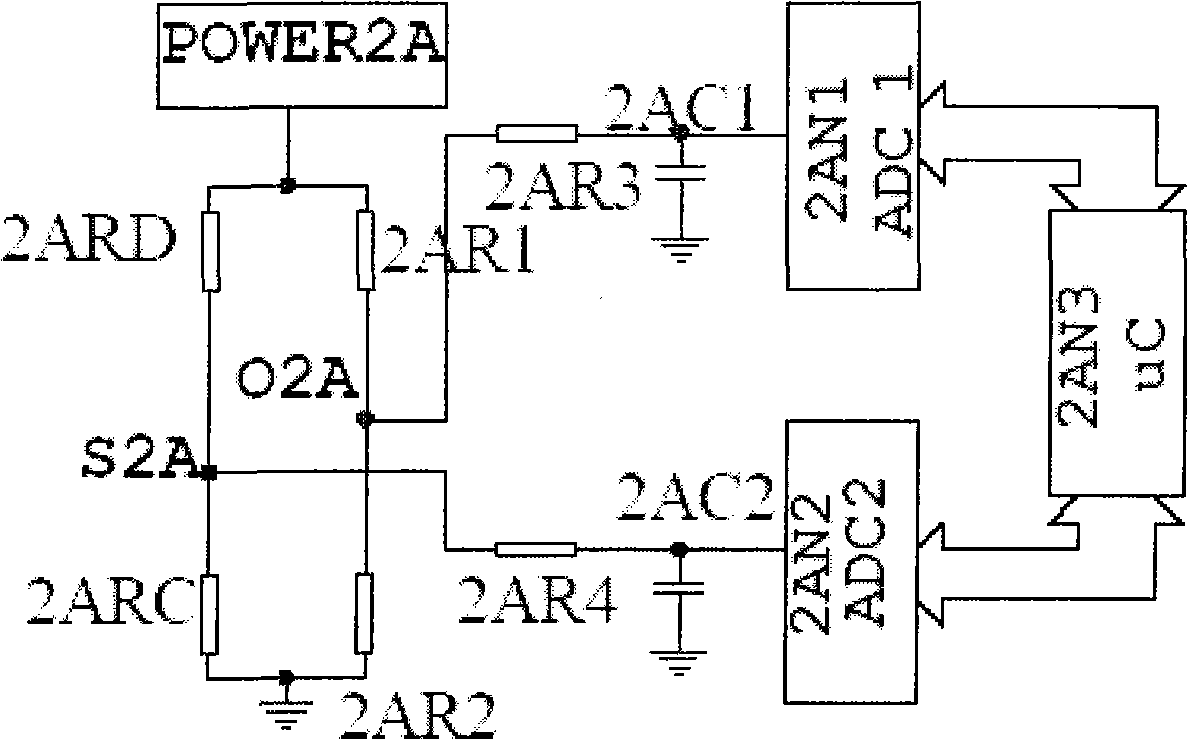

[0027] Such as Figure 2A As shown, the two output terminals O2A and S2A of the sensor are respectively connected with high-resolution AD converters 2AN1 and 2AN2 through the filter circuit, and the output of the AD converters 2AN1 and 2AN2 is sent to the single-chip microcomputer 2AN3.

[0028] Suppose: the potential of O2A point is Vo

[0029] The potential at point S2A is Vs

[0030] Ideally, 2AR1 = 2AR2, Vs-Vo = 0, and the sensor is perfectly balanced. The actual situation is that the sensor that has been continuously energized and aged before leaving the factory (generally 5-7 days) tends to be stable within 5 minutes of being energized at the commissioning site. Since 2AR1 and 2AR2 have high matching accuracy, good symmetry and thermal tracking, it can be considered that Vo at this time is the real zero position of the sensor, and Vs-Vo at this time is the init...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com