Silk screen cleaning agent for silk screen printing

A technology of screen printing and cleaning agent, applied in the field of cleaning agent, can solve problems such as adverse effects on the life of photosensitive products, and achieve the effects of improving adhesion, preventing falling off, and preventing iron ion precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation example of the screen cleaning agent for screen printing is as follows, and the present invention is not limited thereto.

Embodiment 2

[0026]Using a mechanical stretcher, a 325-mesh fabric-shaped stainless steel wire mesh with a thickness of 64.0 μm was stretched on an aluminum die-casting frame with a size of 320×320 mm to produce two stretch plates. One of the above two plates was cleaned with the cleaning solution formulated in Example 1, and the other plate was cleaned with a neutral cleaning agent (Murakami Precision Plate (Kunshan) Co., Ltd. MSP detergent) sold on the market. Clean up. The above two plates were respectively made of diazo series photosensitizer SP-9400 from Murakami Precision Plate (Kunshan) Co., Ltd. sold in the market to form photosensitive plastic films with a thickness of 15 μm. Next, prepare a 30-line 30% halftone dot image polyester positive film, stick the film surface of the positive film close to the film surface of the above-mentioned photosensitive film layer, use a 3kw metal halide lamp as a light source, and carry out the process for 90 seconds from a distance of 80cm. of U...

Embodiment 3

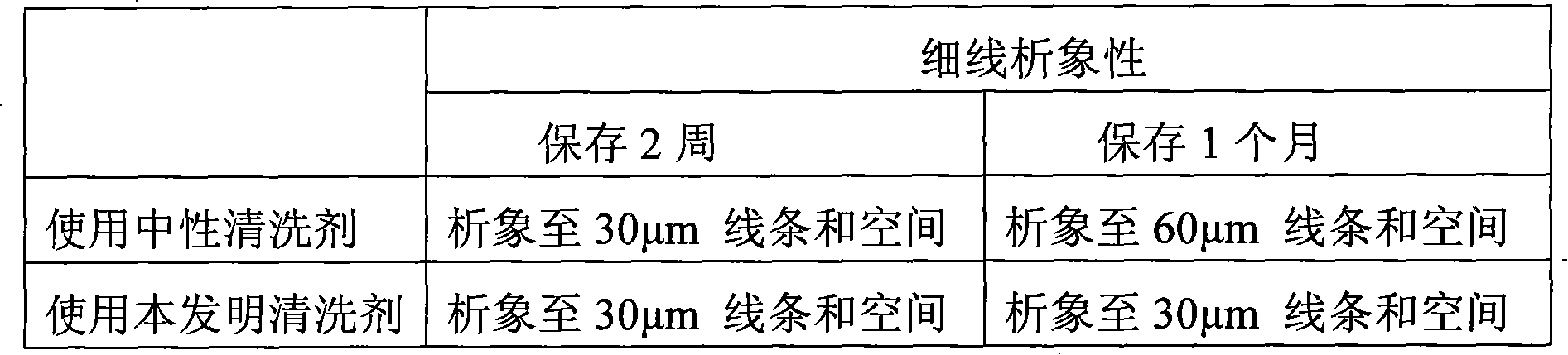

[0030] Using a mechanical stretcher, a 64.0 μm-thick, 325-mesh fabric-shaped stainless steel wire mesh was stretched on an aluminum die-casting frame with a size of 320×320 mm to produce four stretching plates. Among the above-mentioned 4 plates, 2 plates are cleaned with the cleaning liquid prepared in Example 1, and the remaining 2 plates are cleaned with a neutral cleaning agent (Murakami Precision Plate (Kunshan) Co., Ltd., the screen cleaning agent MSP) sold on the market. detergent) for cleaning. After cleaning, a photosensitive resin film with a thickness of 15 μm was formed on the plate with diazo series photosensitizer SP-9400 manufactured by Murakami Precision Plate (Kunshan) Co., Ltd. respectively. These plates were subjected to a storage test in a light-shielded state in an environment with a humidity of 40 to 50% and a temperature of 20 to 50°C. After cleaning the plate with the cleaning agent of the present invention and the neutral cleaning agent of the compari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com