Coloring light-sensitive resin composition for ultraviolet ray laser, method for forming patterns, optical filter and production method thereof and display device

A technology of photosensitive resin and composition, which is applied in the direction of photolithographic exposure equipment, nonlinear optics, microlithography exposure equipment, etc., can solve the problem of no prompt material, etc., and achieve good color characteristics, high productivity, and line width Highly stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0371] Hereinafter, although an Example demonstrates this invention more concretely, unless the summary is exceeded, this invention is not limited to a following Example. In addition, "part" is based on mass unless otherwise indicated.

[0372] Details of the compounds (compounds 1 to 15) used in Examples and Comparative Examples are shown below.

[0373]

Synthetic example 1

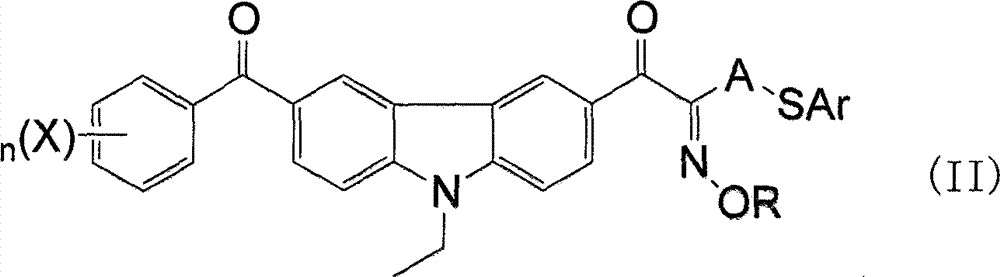

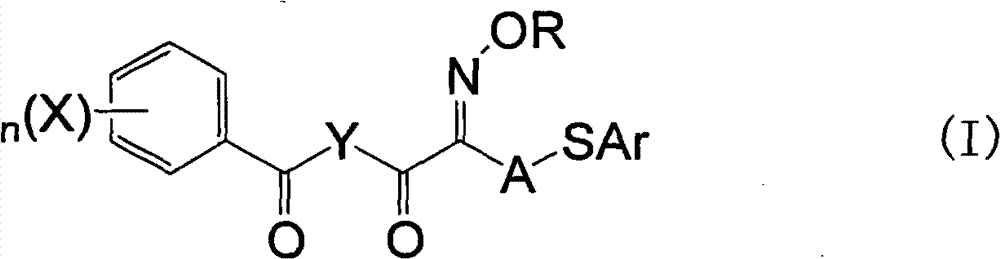

[0374] Synthesis Example 1: Synthesis of Compound 2, the photopolymerization initiator represented by the general formula (I) above

[0375] First, compound D was synthesized according to the following strategy.

[0376] Ethylcarbazole (100.0g, 0.512mol) was dissolved in 260ml of chlorobenzene, and after cooling to 0°C, aluminum chloride (70.3g, 0.527mol) was added. Next, o-chlorotoluene (81.5 g, 0.527 mol) was added dropwise over 40 minutes, the temperature was raised to room temperature, and the mixture was stirred for 3 hours. Then, after cooling to 0°C, aluminum chloride (75.1 g, 0.563 mol) was added. 4-Chlorobutyryl chloride (79.4 g, 0.563 mol) was added dropwise over 40 minutes, warmed up to room temperature, and stirred for 3 hours. The mixed solution of 156 ml of 35 mass % hydrochloric acid aqueous solution and 392 ml of distilled water was cooled to 0 degreeC, and the reaction solution was dripped. The precipitated solid was suction-filtered, washed with distilled ...

Synthetic example 2

[0386] Synthesis Example 2: Synthesis of Compound 3, the photopolymerization initiator represented by the above general formula (I)

[0387] First, the same operation as in Synthesis Example 1 was carried out to synthesize compound D.

[0388]Dissolve the obtained compound D (86.5g, 209mmol) in THF 277ml, add 2,6-dimethylbenzenethiol (30g, 217mmol) and sodium iodide (3.0g, 20.0mmol), and stir at 40°C . Next, sodium hydroxide (8.66 g, 216 mmol) was added to the reaction liquid, and it refluxed at 40 degreeC for 2 hours. Next, after cooling to 0° C., sodium methoxide 28% methanol solution (manufactured by Nippon Shokubai Co., Ltd., SM-28) (48 g, 249 mmol) was added dropwise over 20 minutes, and the temperature was raised to room temperature, followed by stirring for 2 hours. Next, after cooling to 0° C., isoamyl nitrite (29.3 g, 250 mmol) was added dropwise over 20 minutes, the temperature was raised to room temperature, and the mixture was stirred for 3 hours. The reaction s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com