Flat amorphous alloy powder and electromagnetic wave absorber containing same

An amorphous alloy, flat technology, applied in electrical components, magnetic field/electric field shielding, etc., can solve the problems of the preparation method and performance limitation of the absorber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, the alloy composition is selected as Fe 74 Cr 2 Mo 2 sn 2 P 10 Si 4 B 4 C 2 , prepared into spherical amorphous alloy powder by water atomization method, the atomization pressure is 30Kg / cm 2 . Dry the atomized product in a vacuum drying oven at 180° C. for 8 hours, and sieve the dried product to obtain spherical amorphous alloy powder with an average particle size of 40-50 μm.

[0039] Wet ball milling in a planetary ball mill with a ball-to-material ratio of 5:1, a rotational speed of 400 rpm, and a ball milling time of 10 hours and 16 hours to obtain two types of flat powders with different aspect ratios.

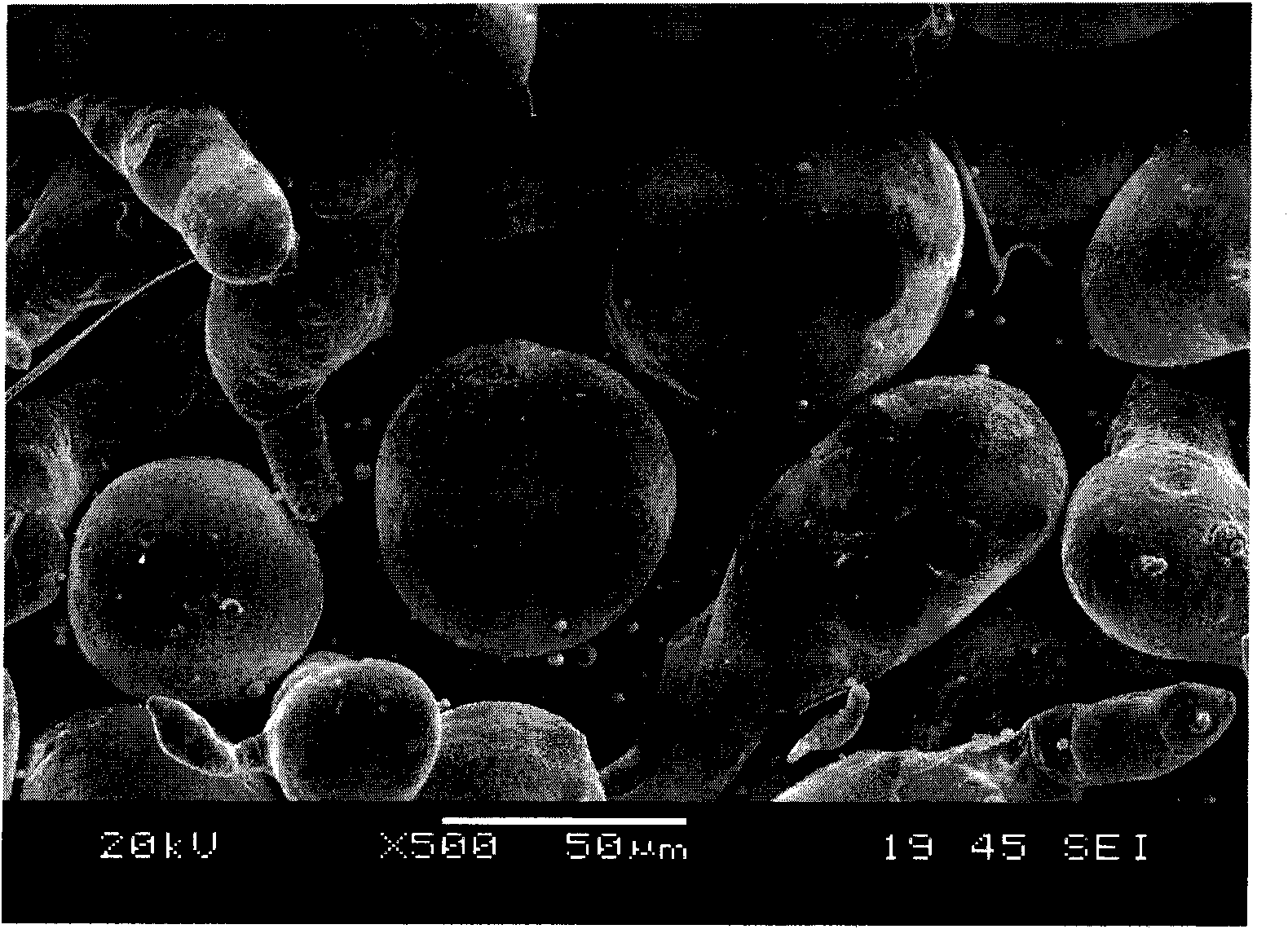

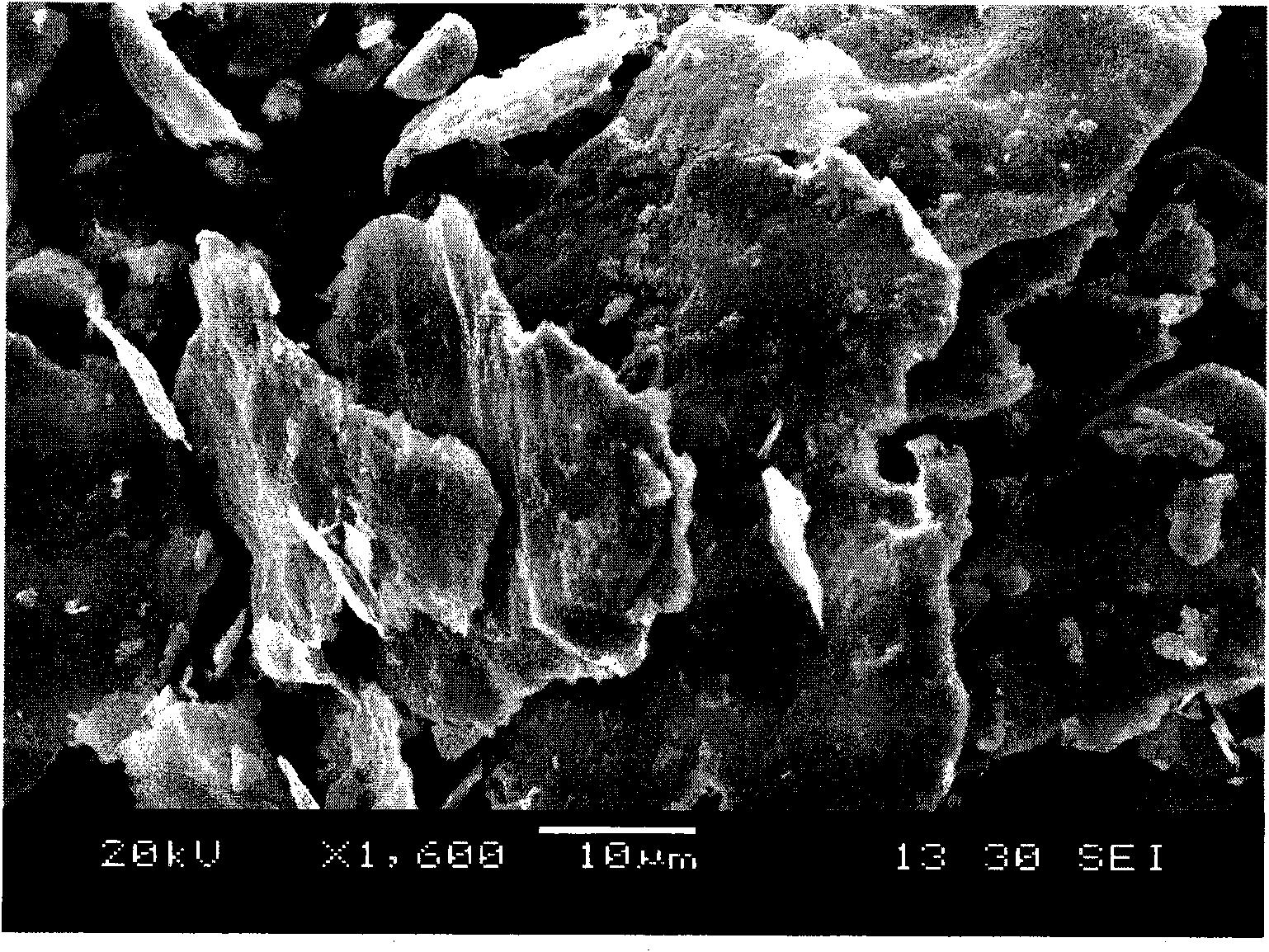

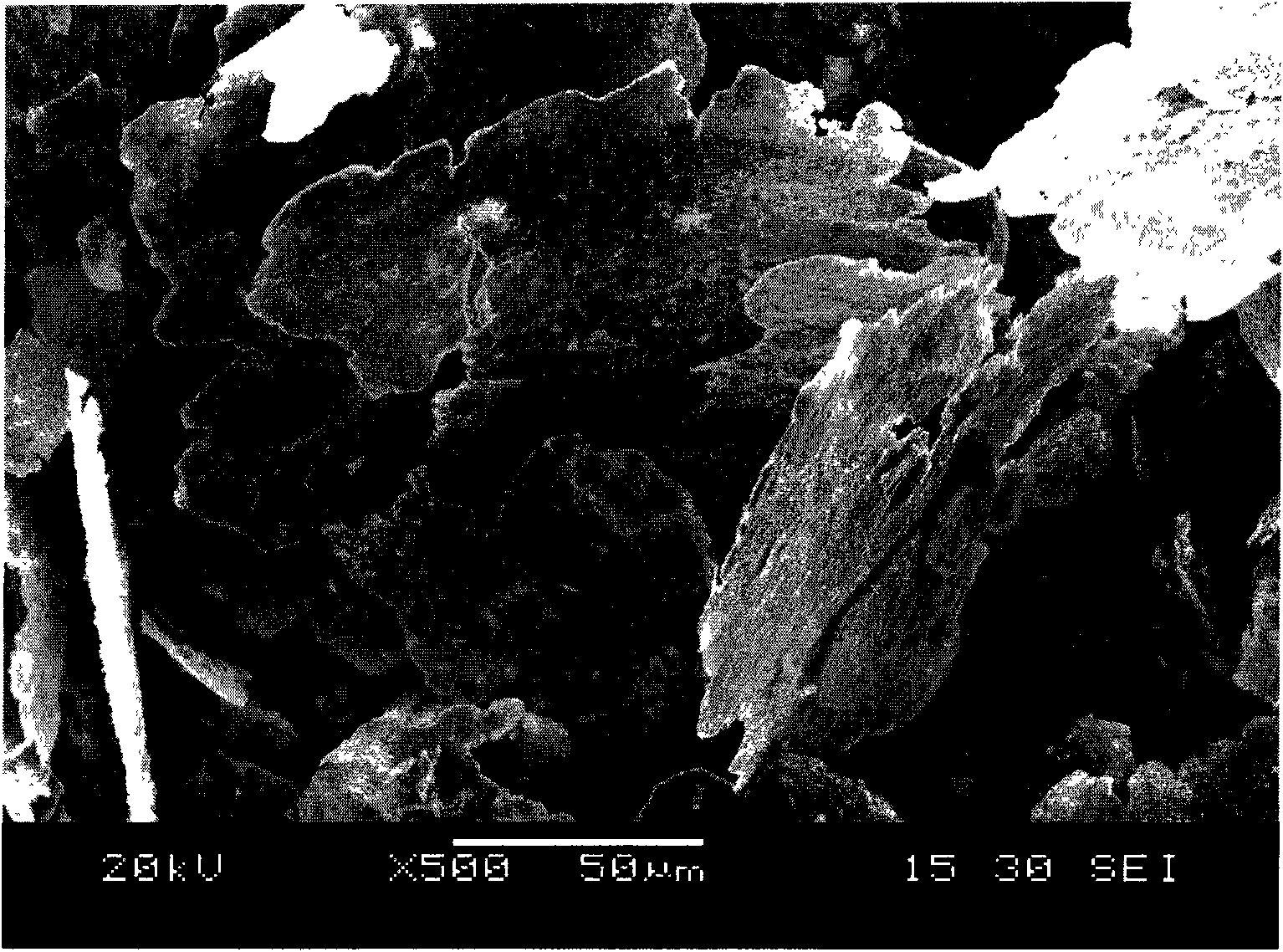

[0040] Powder morphology was observed under a scanning electron microscope ( figure 1 , figure 2 , image 3 ). Depend on figure 1 It can be seen that water atomization produces nearly spherical powders. Depend on figure 2 , image 3 It can be seen that the nearly spherical powder is transformed into a flat powder after ball mi...

Embodiment 2

[0048] Iron-based amorphous alloys with different compositions were used to prepare amorphous alloy powders according to the same atomization method as in Example 1. The alloy composition used is Fe 72 Cr 1 Mo 1 sn 2 P 15 Si 1 B 7.5 C 0.5 , Fe 72 Cr 5 Mo 3 sn 2 P 3 Si 2 B 12 C 1 , Fe 72 Cr 1 Mo 1 sn 3 P 8 Si 8 B 1 C 6 , Fe 73 Cr 2 Nb 5 sn 2 P 2 Si 8 B 6 C 2 , Fe 74 Cr 2 Mo 2 sn 2 P 10 Si 4 B 4 C 2 , Fe 76 Cr 1 Mo 1 al 4 P 8 Si 8 B 1 C 1 , Fe 78 Cr 1 Mo 1 sn 2 P 8 Si 8 B 1 C 1 .

[0049] The prepared atomized powder adopts X-ray diffractometer to measure its crystal structure, such as Image 6 shown. from Image 6 It can be seen that the X-ray diffraction pattern of the obtained powder has no crystallization peak, showing obvious amorphous structure characteristics, which indicates that the alloy powder of the present invention is amorphous. The atomized powder was wet-milled in a planetary ball mill with a ball-to-mater...

Embodiment 3

[0056] The powder of this embodiment is composed of Fe 73 Cr 2 Nb 5 sn 2 P 2 Si 8 B 6 C 2 The iron-based amorphous alloy was prepared into powder by the same atomization method as in Example 1. The flat powder was prepared by the same ball milling process as in Example 2, and then the powder was heat-treated in a vacuum heat treatment with a process parameter of keeping the temperature at 440° C. for 1 hour.

[0057]Disperse the flat powder into thermoplastic polyurethane to prepare absorbers with flat powder filling rates of 20vol.%, 30vol.%, 40vol.%, 50vol.%, 60vol.%, 70vol.%. The specific steps are: a. Use organic solvent nitrogen methyl formamide to dissolve thermoplastic polyurethane to prepare a coating with thermoplastic polyurethane content of 20vol.%. According to the filling rate requirements, add a certain amount of the above-mentioned flat powder and use a mixer at 1000rpm Stir for 1 hour b. Use a stirrer to stir for 1 hour at 1000rpm, so that the preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com