Method for recycling iron and aluminum by particle size grading pretreatment of Bayer process red mud

A technology of Bayer process red mud and recovery method, which is applied in the field of resource utilization of industrial waste residues, and achieves the effects of good economy, good promotion prospects, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

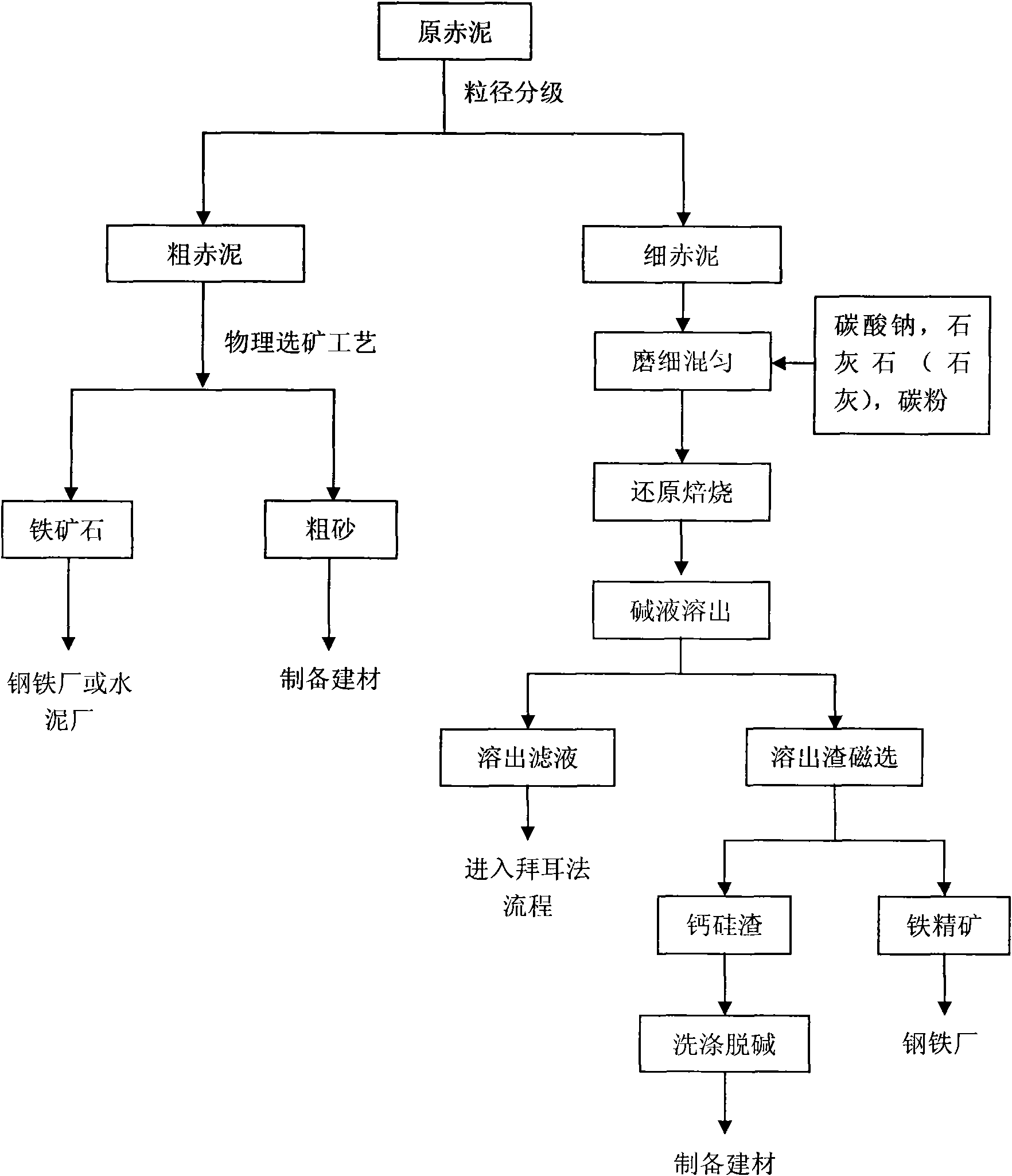

Method used

Image

Examples

Embodiment 1

[0029] (1) Classification of red mud

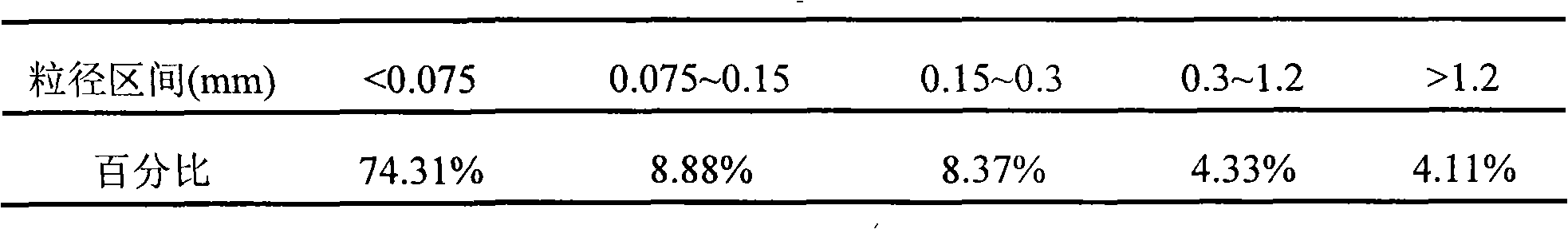

[0030] The Bayer process red mud used in the present invention comes from an alumina plant in Shandong. After classification, the red mud is divided into parts with a particle size of 1.2mm. Among them, the red mud with a particle size of 0.075mm accounts for 25.69% (called coarse red mud) (see Table 1 for details).

[0031] Table 1 Mass specific gravity of red mud with different particle sizes

[0032]

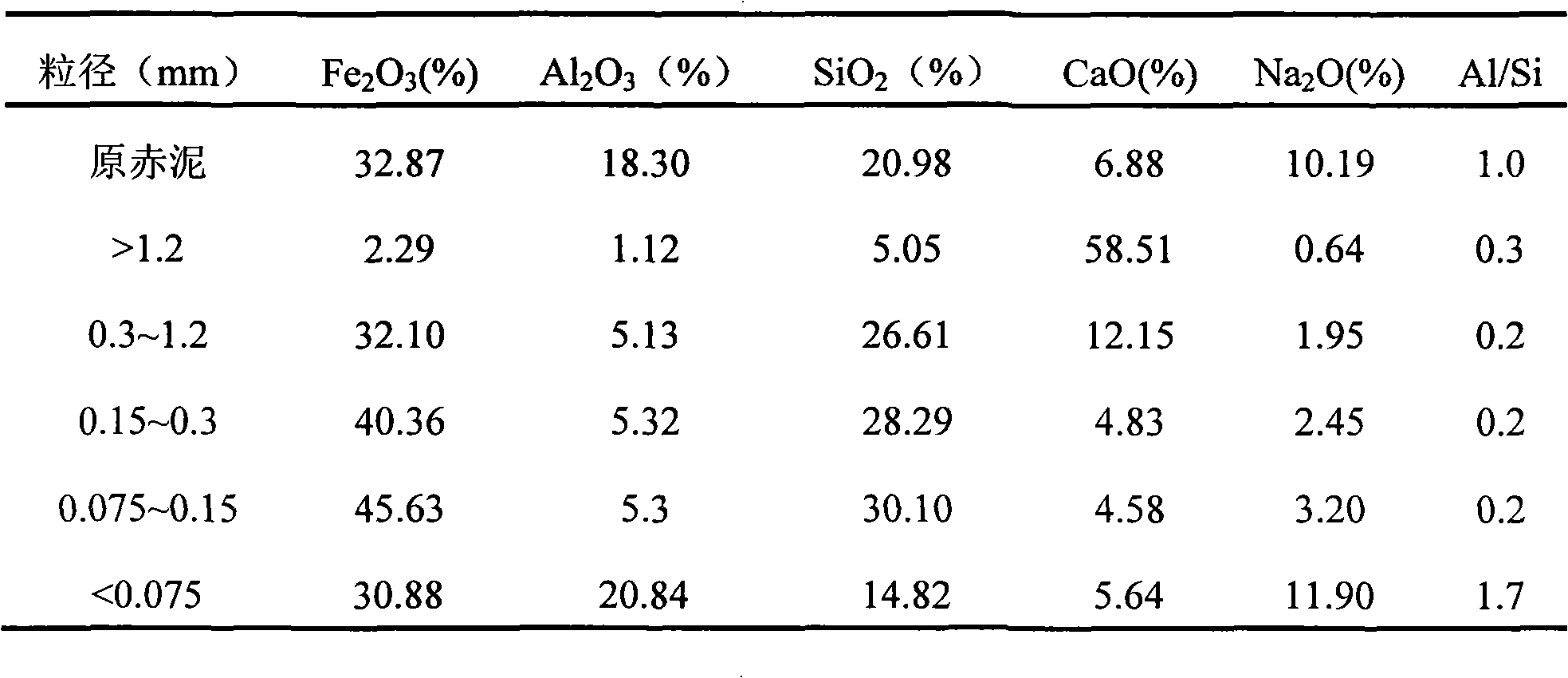

[0033] The chemical composition of red mud with various particle sizes is shown in Table 2. The chemical composition of red mud with a particle size greater than 1.2mm is mainly CaO, and the red mud with a particle size between 0.075mm and 1.2mm contains Fe 2 o 3 , SiO 2 High content, Al 2 o 3 The content of the red mud is lower; the red mud with a particle size of less than 0.075mm is compared with the original red mud SiO 2 The content of Al / Si has decreased significantly, and the Al / Si has increased from 1.0 of the original...

Embodiment 2

[0042] (1) Classification of red mud

[0043] The red mud is classified into coarse red mud with a particle size of >0.075mm and fine red mud with a particle size of <0.075mm through particle size separation. Among them, coarse red mud accounts for 25.91%, and fine red mud accounts for 74.09%. The chemical composition analysis of the two kinds of red mud is shown in Table 3 below.

[0044] Table 3 Chemical composition analysis of coarse and fine red mud after classification

[0045]

[0046] (2) Separation and utilization of iron concentrate and coarse sand in coarse red mud

[0047] Using the method of Example 1, iron ore and sand with an iron grade of 58.13% were separated from the coarse red mud.

[0048] (3) Fine red mud iron and aluminum recovery

[0049] Dried fine red mud and a certain amount of NaCO 3 , CaO and carbon powder are finely ground and mixed, among which NaCO 3 Add according to Na / Al=1.3 (molar ratio), CaO according to Ca / Si=2.3 (molar ratio), add c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com