Preparation method and application of rare earth metal hydroxide or vanadate nano material

A technology of rare earth metal salts and rare earth metals, applied in the fields of rare earth metal compounds, chemical instruments and methods, vanadium compounds, etc., can solve the problems of phase regulation and structure control difficulties, and achieve stable product quality, simple process, and controllable structure strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

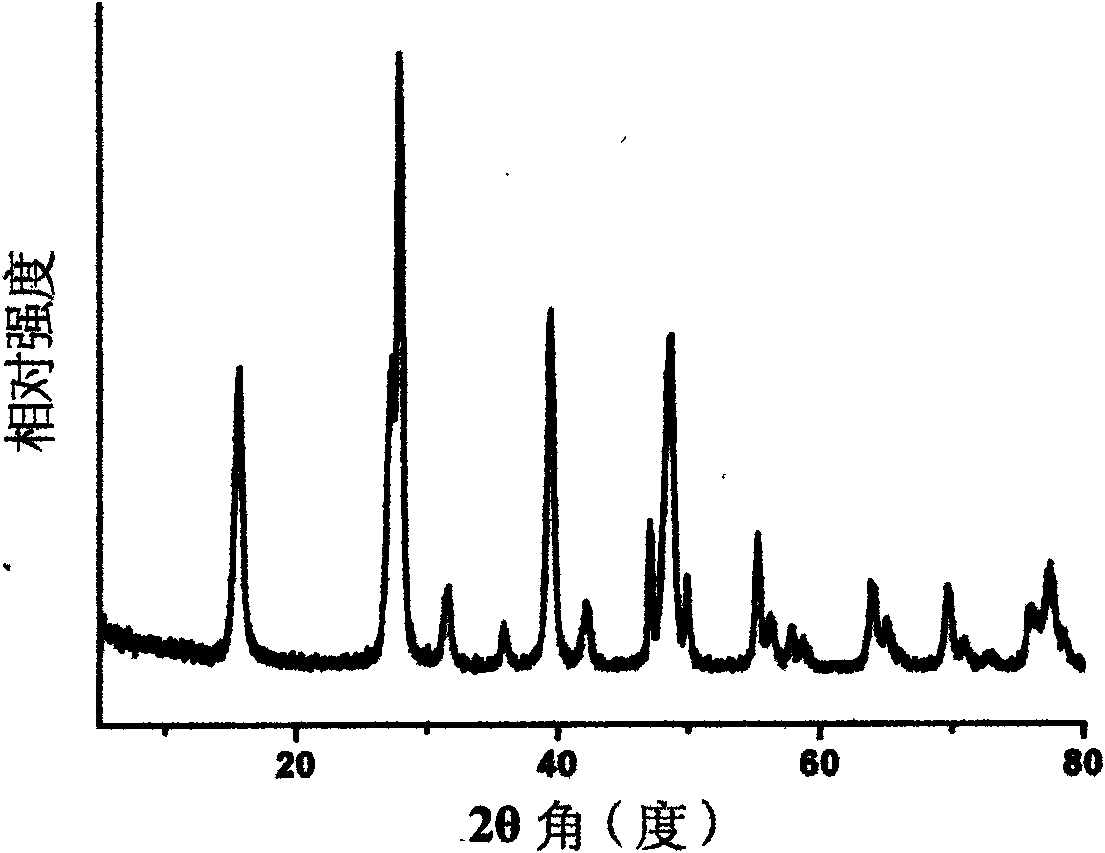

[0038] Example 1: Preparation and structural characterization of lanthanum hydroxide nanoparticles

[0039] At room temperature, the La(NO 3 ) 3 Mix it with NaOH uniformly according to the molar ratio of 1:30, put it in a polytetrafluoroethylene or stainless steel liner hydrothermal reaction kettle, add deionized water to make La(NO 3 ) 3The concentration is 0.0001M, then add a mixture of ionic liquid 1-butyl-3-methylimidazole bromide and absolute ethanol with a volume ratio of 1:90, and stir for 10 to 30 minutes; ℃ for 1 to 2 hours, after the reaction is completed, cool to room temperature, wash with deionized water and absolute ethanol for 3 to 4 times to neutrality, and vacuum dry at 80 ℃ for 6 hours to obtain a white powder. The XRD spectrum of the sample prepared under the conditions of Example 1 is as follows: figure 1 Show: product is the lanthanum hydroxide pure phase of hexagonal phase; SEM scanning electron microscope ( figure 2 ) shows that the product is a na...

Embodiment 2

[0041] Example 2: Preparation and structural characterization of lanthanum hydroxide nanorods

[0042] At room temperature, the LaCl 3 Mix evenly with NaOH at a molar ratio of 1:30, place in a polytetrafluoroethylene or stainless steel liner hydrothermal reactor, add deionized water to make LaCl 3 The concentration is 0.0015M, then add the mixed solution of ionic liquid 1-hexadecyl-3-methylimidazole bromide and absolute ethanol with a volume ratio of 1:10, and stir for 10 to 30 minutes; in a closed reaction kettle React at 170°C for 4-6 hours, cool to room temperature after the reaction is complete, wash the product with deionized water and absolute ethanol for 3-4 times to neutrality, and vacuum-dry at 80°C for 6 hours to obtain dry white powder. The product is identified as lanthanum hydroxide by X-ray powder diffraction, corresponding to the standard card (JCPDS card 36-1481), belonging to the hexagonal crystal system, and the space group is P63 / m; SEM scanning electron mi...

Embodiment 3

[0044] Example 3: Preparation and structural characterization of lanthanum hydroxide nanowires

[0045] At room temperature, the La 2 (SO 4 ) 3 Mix with NaOH uniformly according to the molar ratio of 1:30, place it in a polytetrafluoroethylene or stainless steel liner hydrothermal reaction kettle, add deionized water to make La 2 (SO 4 ) 3 The concentration is 0.002M, then add a mixture of ionic liquid 1-ethyl-3 imidazolium acetate and absolute ethanol with a volume ratio of 1:10, and stir for 10 to 30 minutes; React for 7 to 8 hours. After the reaction is completed, cool to room temperature, wash with deionized water and absolute ethanol for 3 to 4 times until neutral, and vacuum dry at 80° C. for 6 hours to obtain a white powder. In order to compare the positive effect of ionic liquids in hydrothermal synthesis, samples were prepared without adding ionic liquid 1-ethyl-3-methyl imidazolium acetate and other experimental conditions were the same. After comparing the X-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com