Nuclear shell nanometer catalyst packaged with noble metal nanometer grains and method thereof

A nano-catalyst and nano-particle technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of poor catalyst stability, chemical affinity mismatch, easy Agglomeration and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

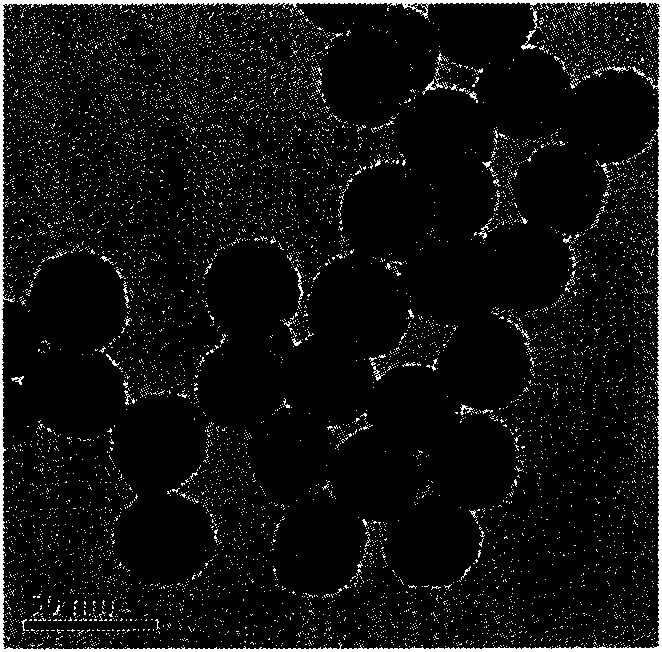

[0086] Example 1: Making 2%Pd@SiO 2 (Spherical) Core-shell Nanocatalysts

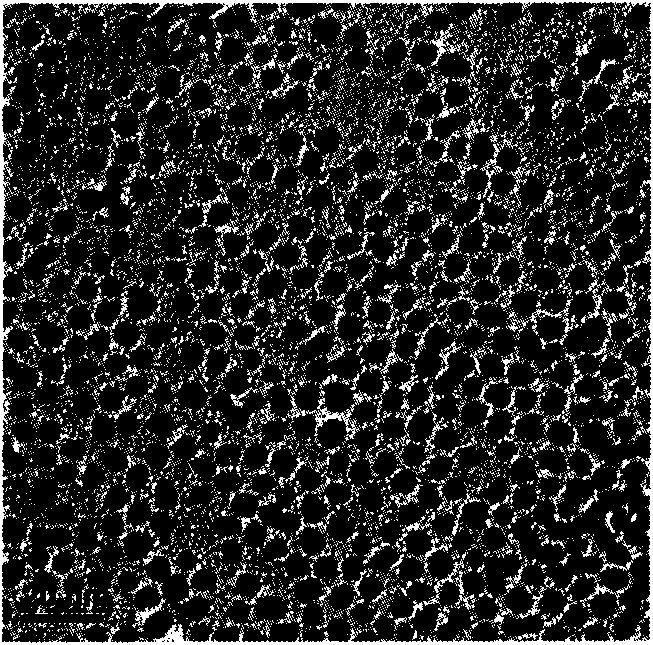

[0087] Weigh 15.2mg of palladium acetylacetonate, measure 0.75ml of oleylamine, 0.25ml of oleic acid, 50ul of triphenylphosphine and 2ml of diphenyl ether solution, stir well, put it into a microwave reactor, react at 180°C for 1h, and take out the sample Wash with absolute ethanol, dissolve with cyclohexane (such as figure 1 ). Weigh 35mg of iron acetylacetonate, measure 1.5ml of oleylamine, 1.1ml of oleic acid and 10ml of n-octanol solution, put them into a three-necked bottle, heat to 80°C for 1h, draw a vacuum, replenish nitrogen several times, Heated to 180°C in medium temperature, maintained for 2h, cooled to room temperature, washed with absolute ethanol, and then dissolved in an appropriate amount of cyclohexane solution (such as figure 2 ). Weigh 4.672g Brij56 and dissolve in 20ml cyclohexane, measure 0.2ml deionized water, then stir overnight, measure 0.7ml ammonia water and stir for 0.5h...

Embodiment 2

[0089] Example 2: Making 1.3%Pd@SiO 2 (Spherical) Core-shell Nanocatalysts

[0090] Weigh 10mg palladium acetylacetonate, measure 0.5ml oleylamine, 0.2ml oleic acid, 10ul triphenylphosphine and 2ml diphenyl ether solution, stir evenly, put it into a microwave reactor, react at 180°C for 1h, take out the sample for Wash with absolute ethanol and dissolve with cyclohexane. Weigh 20mg of iron acetylacetonate, measure 1.5ml of oleylamine, 1.1ml of oleic acid and 10ml of n-octanol solution, put them into a three-necked bottle, heat to 80°C for 1h, draw a vacuum and replenish nitrogen several times, Heated to 180°C in medium temperature, maintained for 2h, cooled to room temperature, washed with absolute ethanol, and then dissolved in an appropriate amount of cyclohexane solution. Weigh 4.672g Brij56 and dissolve in 20ml cyclohexane, measure 0.2ml deionized water, then stir overnight, measure 0.7ml ammonia water and stir for 0.5h, then measure 1.5ml tetraethoxysilane, heat to 50°C...

Embodiment 3

[0091] Example 3: Making 4%Pd@SiO 2 (Spherical) Core-shell Nanocatalysts

[0092] Weigh 30mg of palladium acetylacetonate, measure 3ml of oleylamine, 1ml of oleic acid, 200ul of triphenylphosphine and 5ml of diphenyl ether solution, stir well and put it in a microwave reactor, react at 180°C for 2h, take out the sample with anhydrous Wash with ethanol and dissolve with cyclohexane. Weigh 70mg of iron acetylacetonate, measure 1.5ml of oleylamine, 1.1ml of oleic acid and 10ml of n-octanol solution, put them in a three-necked bottle, heat to 80°C for 1h, draw vacuum, supplement nitrogen several times, Heated to 180°C in medium temperature, maintained for 2h, cooled to room temperature, washed with absolute ethanol, and then dissolved in an appropriate amount of cyclohexane solution. Weigh 4.672g Brij56 and dissolve in 20ml cyclohexane, measure 0.2ml deionized water, then stir overnight, measure 0.7ml ammonia water and stir for 0.5h, then measure 1.5ml tetraethoxysilane, heat to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com