Method for manufacturing body-contact structure of partially depleted SOI MOSFET

A body contact and device technology, which is applied in the field of body contact structure of partially depleted silicon-on-insulator devices, can solve the problems of increased body parasitic capacitance, prolonged body discharge time, unfavorable floating body effect, etc., and achieves reduced body lead-out resistance, Inhibition of floating body effect, inhibition of possession effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail in conjunction with specific embodiments and with reference to the accompanying drawings.

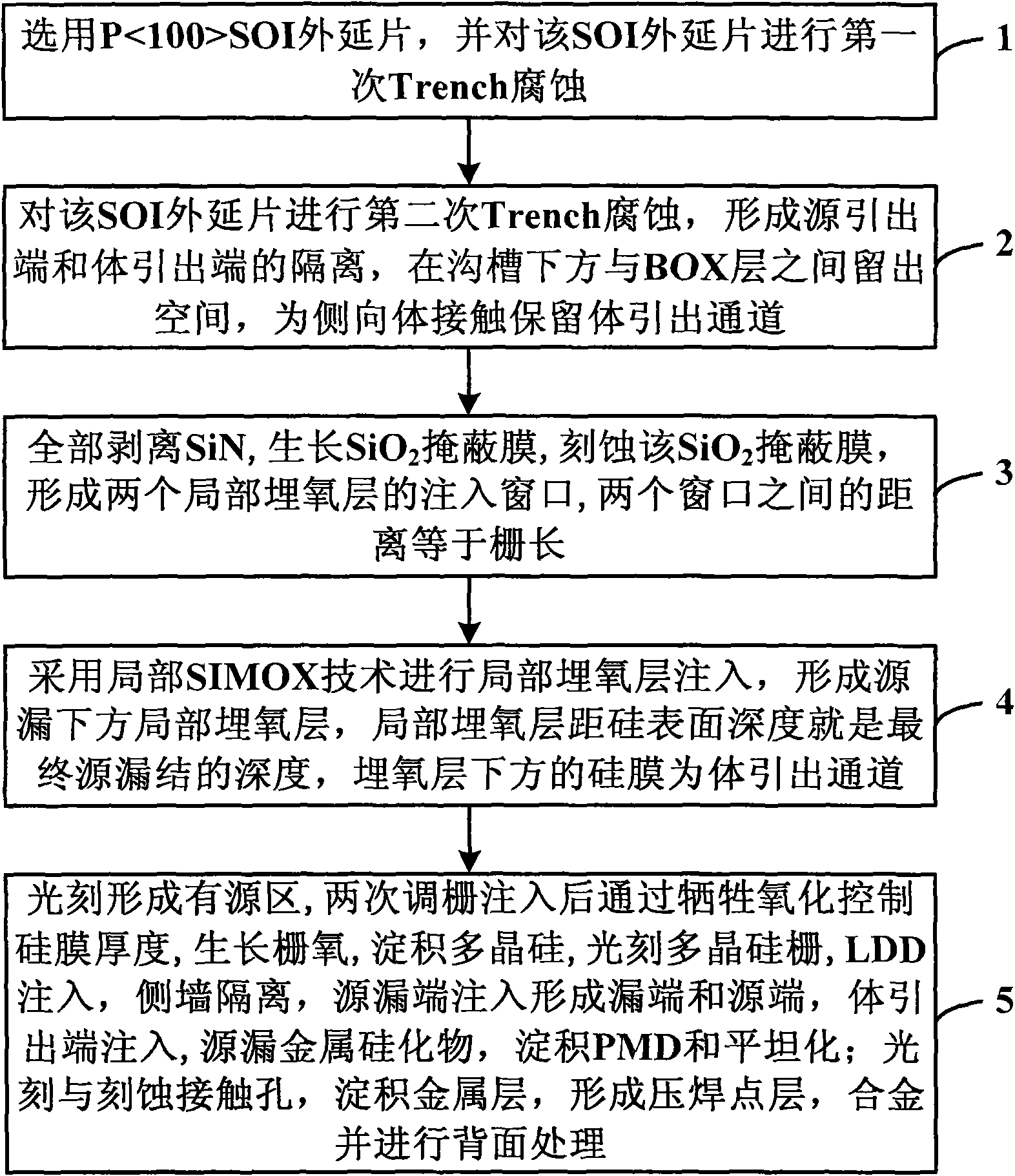

[0036] figure 1 It is a flow chart of the method for manufacturing a body contact structure of a partially depleted SOI device according to the present invention. The specific implementation of the structure of the present invention will be described in detail below with reference to the accompanying drawings.

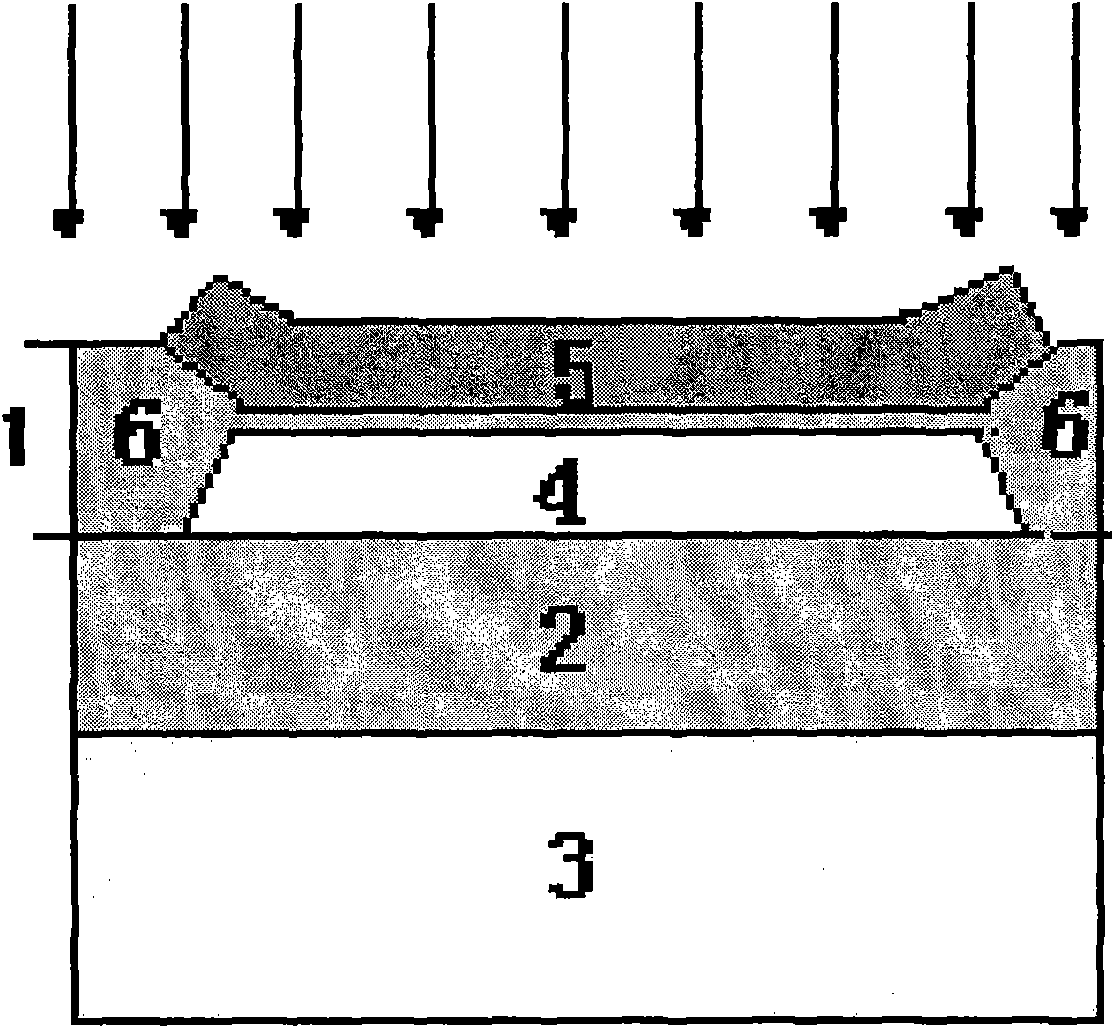

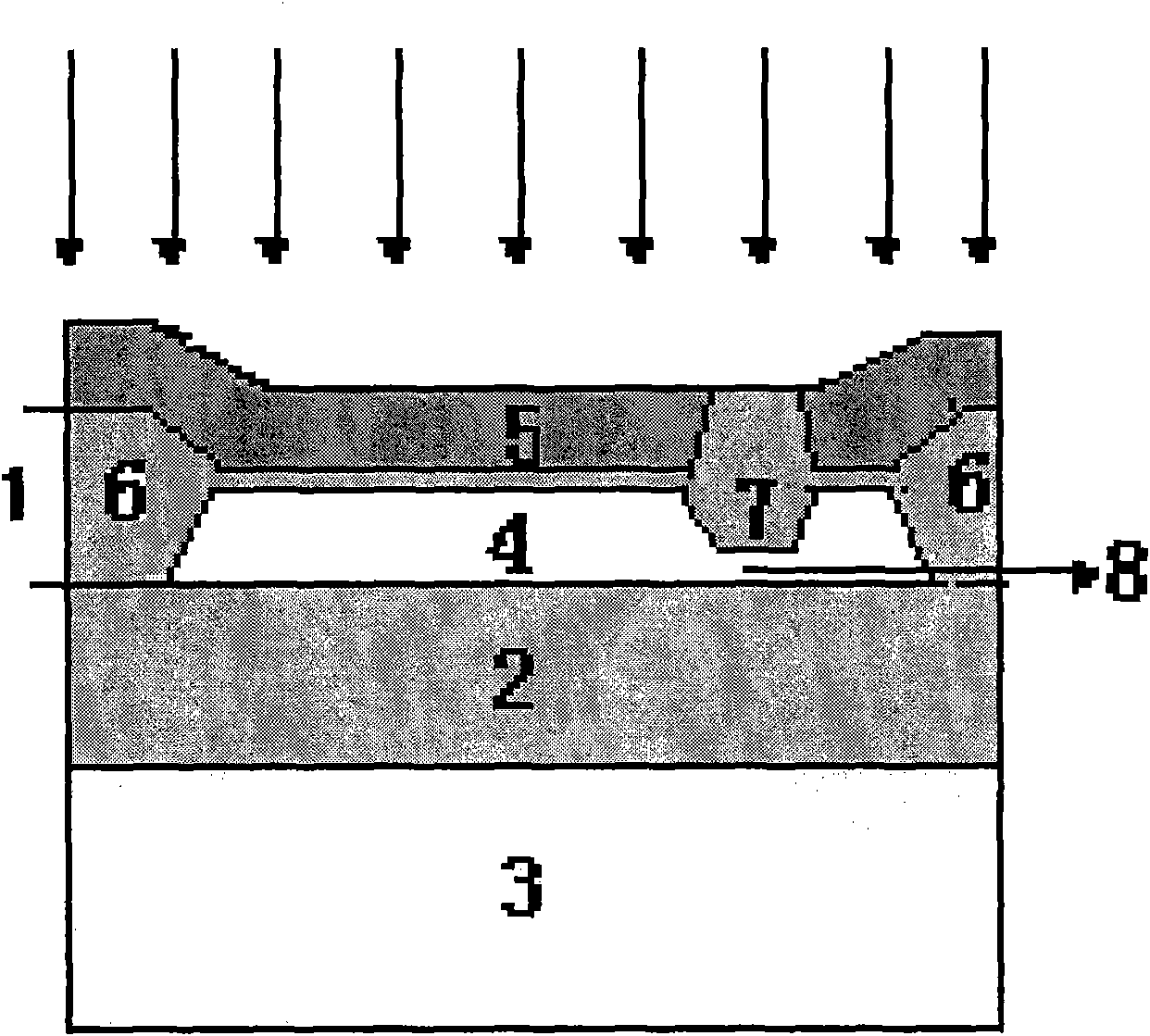

[0037] Step 1, such as figure 2 As shown, select P SOI epitaxial wafer, silicon film (1) thickness of 600nm, BOX layer (2) thickness of 400nm, substrate (3) thickness of 2000nm, gettering oxidation, P-well exposure, P-well (4) injection, injection B+ energy 60KEV, dose 8.5E12, grow SiO 2 Oxide layer, grow SiN (5), etch SiN to form the STI isolation window, perform the first trench etching, the trench reaches th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com