Method for manufacturing full-fiber quarter wave plate

A production method and an all-fiber technology, applied in the direction of voltage/current isolation, polarization components, etc., can solve the problems of complex equipment, high cost, and low feasibility, and achieve low production cost, high welding success rate, and simple production equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

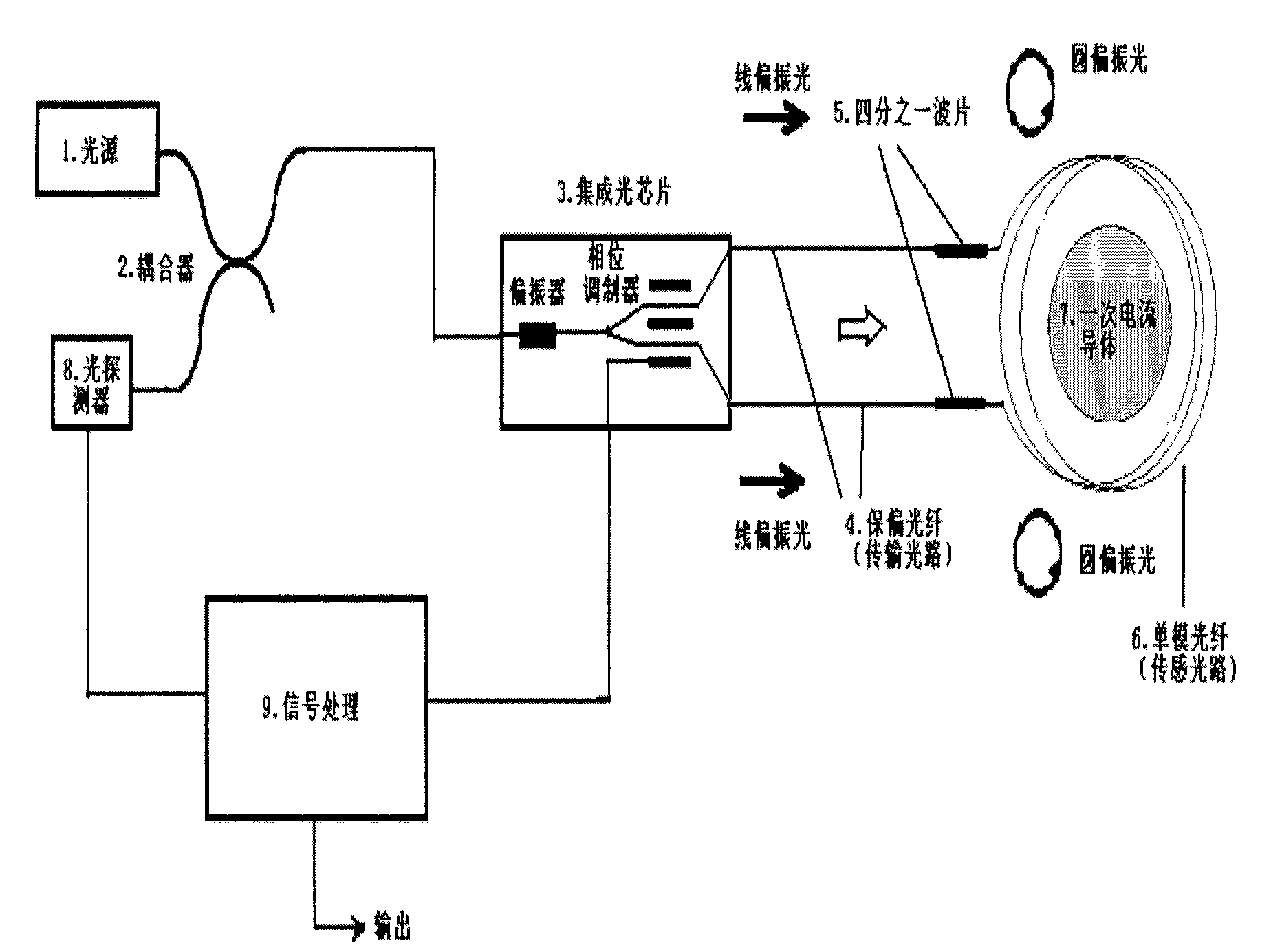

[0028] see figure 2 The optical system structure of the Sagnac interferometer annular all-fiber current transformer of the present invention is illustrated.

[0029] Like most optical current transformers, Sagnac interferometric all-fiber current transformers are also made according to the Faraday effect. When the propagation direction of a beam is parallel to the direction of the adjacent magnetic field, then the circular component in the polarization state of the beam must produce a phase shift proportional to the magnetic field strength. The polarity of this phase shift depends on the direction of the magnetic field relative to the propagation of the beam. That is to say, this phenomenon is a non-reciprocal optical process. That is, the total polarization rotation angle after the light beam passes through the quartz fiber core twice forward and backward is not zero, but the superposition of the two rotation angles. If it passes N times, the total rotation angle increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com