Method for continuous microwave expansion of cut tobacco

A technology of microwave expansion and shredded tobacco, which is applied in the cyclic process of shredded tobacco expansion and the field of shredded tobacco expansion technology, which can solve the problems of poor filling performance, high energy consumption, and failure of continuous production of expanded shredded tobacco, and achieve the effect of stable temperature changes inside and outside shredded tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

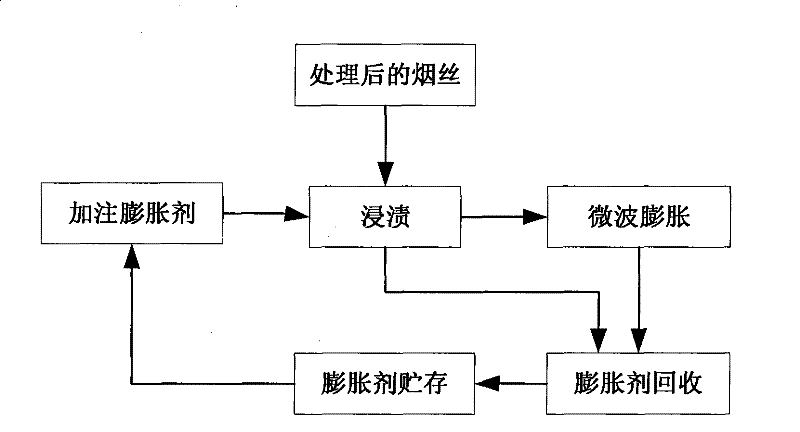

[0064] Such as figure 1 As shown, the shredded tobacco is pretreated so that its water content is 15% of the weight of the shredded tobacco, and 200Kg of the shredded tobacco after treatment is added to an impregnation tank that has been preheated to 70°C; the impregnation tank is evacuated to a pressure of 0.01 Mpa; Add 100Kg liquid expansion agent in dipping tank, described expansion agent is by 85% pentafluorobutane (1,1,1,3,3-pentafluorobutane), 15% heptafluoropropane (1,1 , 1,2,3,3,3-heptafluoropropane) mixture, and then about 70Kg (300Kg) of liquid expansion agent is vaporized and passed into the impregnation tank to increase the pressure in the impregnation tank to 0.8Mpa and the temperature to 110 °C, soak for 30 minutes under the above temperature and pressure conditions;

[0065] After the shredded tobacco is soaked, the gas and liquid expansion agents are recycled and reused separately. After the recycling is completed, the shredded tobacco is unloaded and sent to ...

Embodiment 2

[0067] Pretreat the shredded tobacco so that its water content is 17% of the weight of the shredded tobacco. Take 200Kg of the shredded tobacco after treatment and add it to a dipping tank that has been preheated to 65°C; vacuumize the dipping tank to keep the pressure at 0.03Mpa; Add 200Kg liquid expansion agent in the dipping tank, described expansion agent is 80% pentafluorobutane (1,1,1,3,3-pentafluorobutane), 20% pentafluoropropane (1,1, 1,3,3-pentafluoropropane), and then vaporize 200Kg of liquid expansion agent into the impregnation tank to increase the pressure in the impregnation tank to 0.5Mpa and the temperature to 100°C. Immerse for 10min under the conditions;

[0068] After the shredded tobacco is soaked, the gas and liquid expansion agents are recycled and reused separately. After the recycling is completed, the shredded tobacco is unloaded and sent to the microwave expansion equipment. The microwave power density is 8KW / m 2 , expand the cut tobacco at a tempera...

Embodiment 3

[0070] Pretreat the shredded tobacco so that its water content is 25% of the weight of the shredded tobacco. Take 200Kg of the shredded tobacco after treatment and add it to a dipping tank that has been preheated to 75°C; vacuumize the dipping tank to keep its pressure at 0.005Mpa; Add 130Kg of liquid expansion to the dipping tank, the expansion agent is a mixture of 95% pentafluorobutane and 5% hexafluoropropane, and then vaporize 190Kg of the liquid expansion agent into the dipping tank to increase the pressure in the dipping tank to 0.7Mpa, the temperature is raised to 80°C, and immersed for 20min under the above temperature and pressure conditions;

[0071] After the shredded tobacco is soaked, the gas and liquid expansion agents are recycled and reused separately. After the recycling is completed, the shredded tobacco is unloaded and sent to the microwave expansion equipment. The microwave power density is 7KW / m 2 , at a temperature of 35-40° C. and under normal pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com