Microchannel condenser

A condenser and micro-channel technology, which is applied in the field of parallel-flow condensers for micro-channels, can solve problems such as unreasonable flow path design, and achieve the effects of reasonable structural design, enhanced pressure resistance, and improved heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

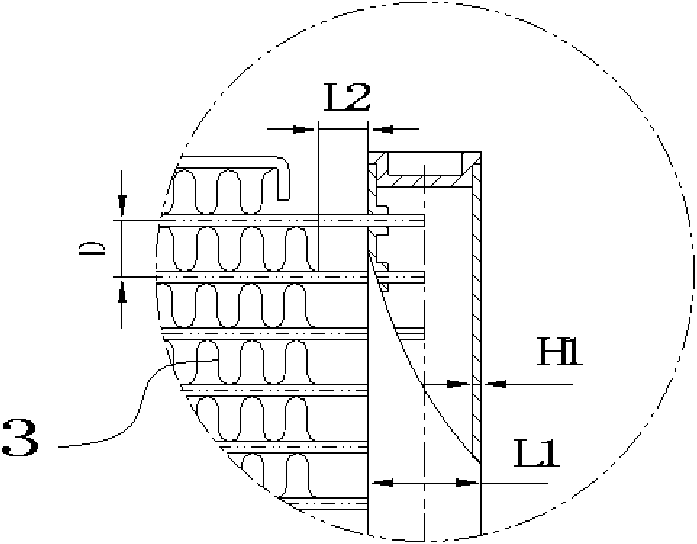

[0024] Embodiment one, see figure 1 and figure 2 , this micro-channel condenser includes two parallel left headers 1 and right headers 5, between the two headers is provided with multi-layer flat tubes 2, the flat tubes 2 communicate with the inner chambers of the two headers, in the flat There are fins 3 extending in a sine wave between the tubes 2, and a partition 7 is inserted in the inner cavity of the two headers. The partition 7 seals and separates the two headers into multiple chambers, namely, the inlet tube and the inlet tube. Working area of the outlet pipe.

[0025] End caps 4 capable of sealing the headers are respectively provided at both ends of the left and right headers, and an inlet pipe 6 and an outlet pipe 8 are arranged on the right header 5 .

[0026] The upper and lower sides of the flat tube 2 are respectively provided with side plates 9 , and fins 3 are also provided between the flat tube 2 and the side plates 9 .

[0027] Both the header and the ...

Embodiment 2

[0031] Embodiment 2, the structure of this embodiment is similar to that of Embodiment 1, the difference is that the outer diameter and wall thickness of the header are 26 ± 1 mm × 1.9 ± 0.2 mm, the width of the flat tube is set to 20 ± 0.2 mm, and the number of holes inside the flat tube The number is 12, and the width of the fins 3 is also set to 20±0.2mm.

Embodiment 3

[0032] Embodiment 3, the structure of this embodiment is similar to that of Embodiment 1, the difference is that the outer diameter and wall thickness of the header are 32 ± 1 mm × 2.5 ± 0.2 mm, the width of the flat tube is set to 25 ± 0.2 mm, and the number of holes inside the flat tube The number is 14, and the width of the fins 3 is also set to 25±0.2mm.

[0033] Similarly, the header, the flat tube 2, the number of holes in the flat tube and the fins 3 have other optimal size configurations.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Side wall thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com