Pulping and papermaking process and equipment

A technology for pulping and papermaking and technology, which is applied in the field of new pulping and papermaking technology to achieve the effects of reducing processing steps, shortening processing time, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

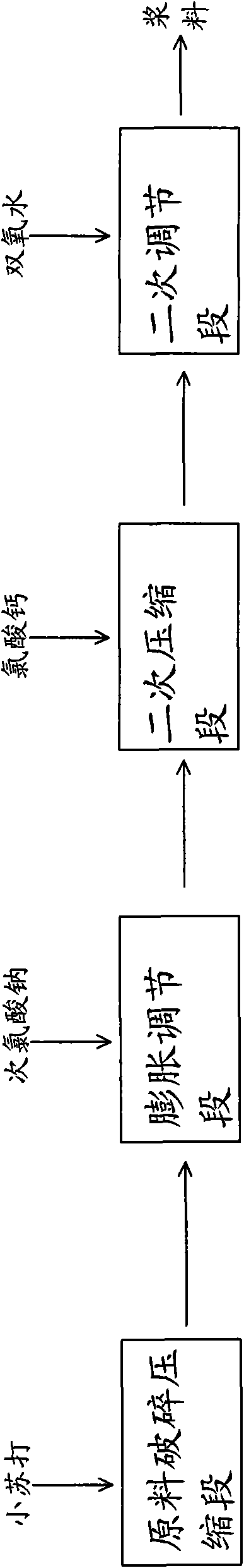

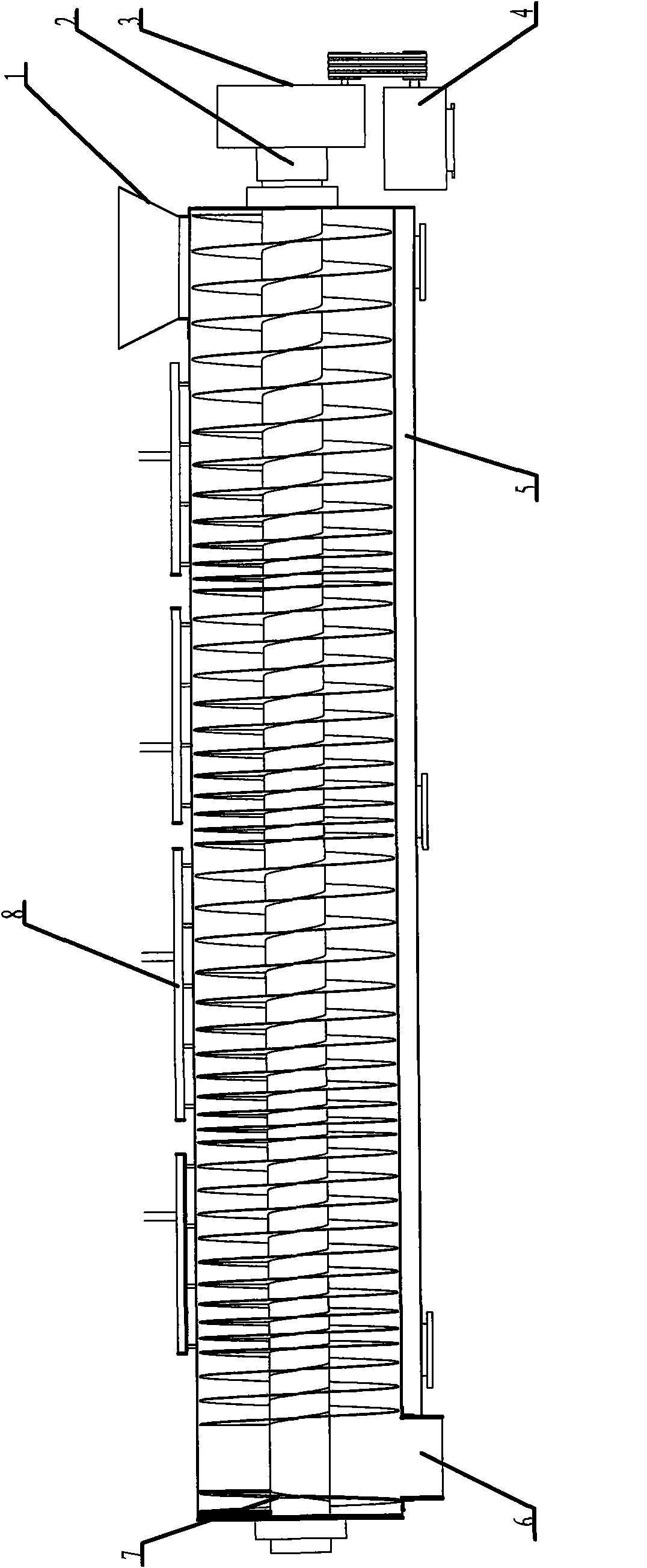

[0042] A kind of pulping and papermaking process, including pretreatment, after cutting the raw material (wheat straw) containing the pulpable fiber into 6cm small sections, directly sending it into the soaking device for soaking, the adopted soaking liquid is clear water, soaking to the dry matter of the raw material The concentration is 25%, and then the pretreated raw material is continuously passed into the reaction device containing four slurry-forming sections, and the slurry-forming agent is added during the movement of the raw material. The four slurry-forming sections include :

[0043] (1) Raw material crushing and compression section; the reaction temperature in this section is 35-45°C, and the compression ratio of raw material is 3:1; The consumption of alkaline treatment liquid is 5.5% of dry matter weight in the mixed raw material;

[0044] After going through this treatment section, the raw material gradually changes from a mixed system of dry matter and pre-so...

Embodiment 2

[0052] A pulping and papermaking process, including pretreatment, after cutting the wheat straw raw material containing pulpable fibers into small sections of 5 cm, it is directly sent to a soaking device for soaking, the soaking liquid used is clear water, and the concentration of the dry matter of the raw material after soaking is 35%, and then the pretreated raw material is continuously passed into the reaction device containing two slurry-forming sections, and slurry-forming agents are added during the movement of the raw material. The two slurry-forming sections include:

[0053] (1) Raw material crushing and compression section; the reaction temperature in this section is 35-45°C, and the compression ratio of raw material is 3.3:1; the treatment agent added in this slurry section is weakly alkaline treatment liquid, sodium silicate, the The consumption of weak alkaline treatment liquid is 3.5% of dry matter weight in the mixed raw material;

[0054] After this treatment ...

Embodiment 3

[0059] A kind of pulping and papermaking process, including pretreatment, after cleaning the wheat straw raw material containing pulpable fiber, cutting it into small sections of 7 cm, and then directly sending it into a soaking device for soaking, and the soaking liquid adopted is an aqueous solution of baking soda; The pretreated raw materials are continuously fed into the reaction device containing two slurry-forming sections, and slurry-forming agents are added during the movement of the raw materials. The two slurry-forming sections include:

[0060] (1) Compression section: the reaction temperature in this section is 85-93°C, and the compression ratio of raw materials is 2.8:1; the treatment agent added in the compression section is an acidic chlorine-containing oxidant, calcium chlorate, the amount of the treatment agent 9-10% of the weight of dry matter in the mixed raw materials;

[0061] After this treatment section, the raw material system is close to pulp, and its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com